High voltage lithium ion battery functional electrolyte and preparation method and application

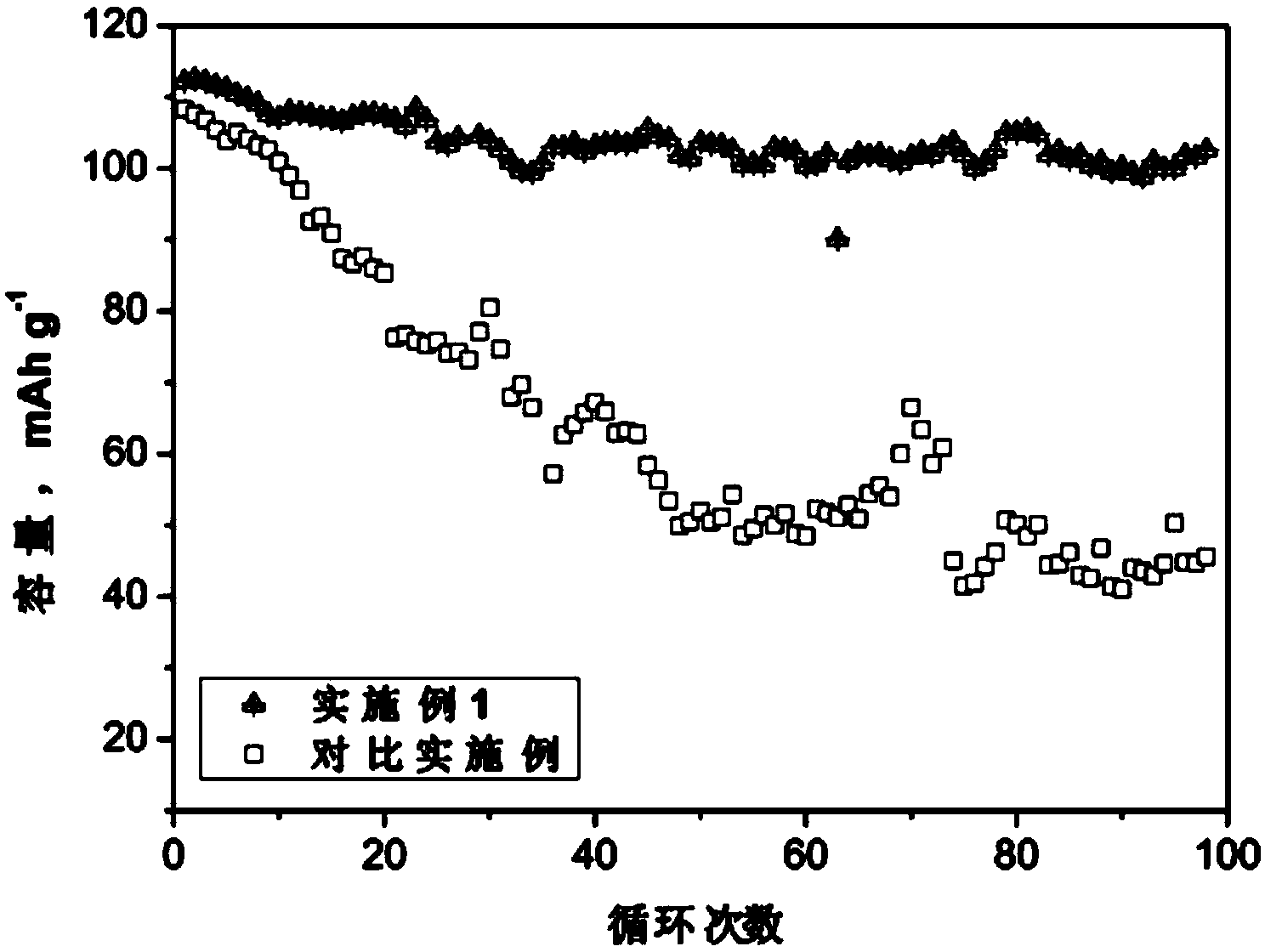

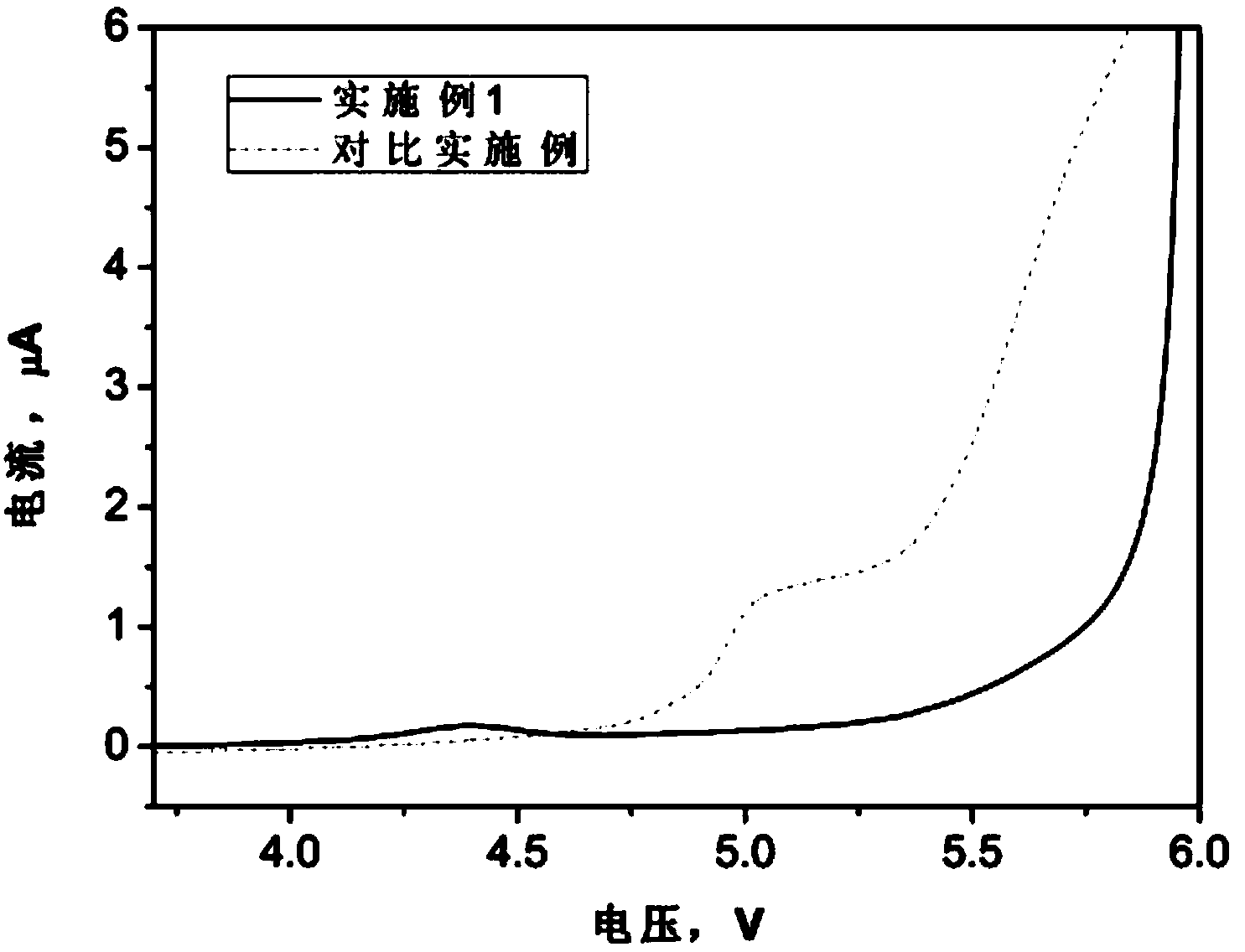

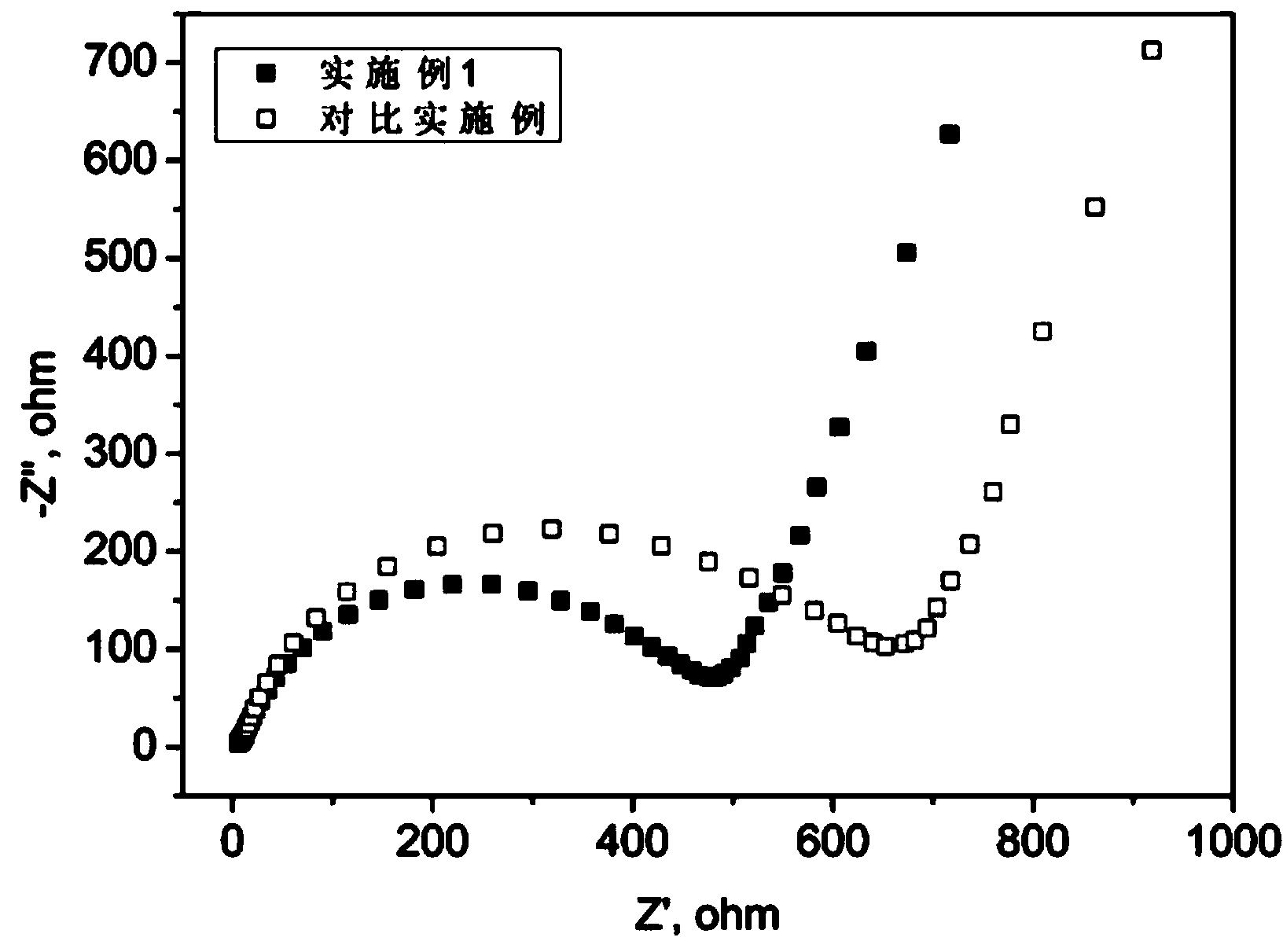

A lithium-ion battery and electrolyte technology, which is applied in the field of high-voltage lithium-ion battery functional electrolyte and preparation, can solve the problems of unable to form graphite electrode interface, low conductivity, high viscosity, etc., to achieve the suppression of dissolution phenomenon and small battery impedance , the effect of good charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Mix cyclic carbonate solvent ethylene carbonate (EC) and linear carbonate solvent dimethyl carbonate (DMC) by mass ratio EC:DMC=1:2, and adopt Molecular sieve, calcium hydride, and lithium hydride are purified to remove impurities and water to obtain a mixed solvent; the conductive lithium salt LiPF 6Dissolve in a mixed solvent of ethylene carbonate and dimethyl carbonate, stir evenly to obtain a common electrolyte; among them, the conductive lithium salt LiPF 6 The final concentration in ordinary electrolyte is 1.0mol / L;

[0046] (2) Add dimethyl phenyl phosphate to the common electrolyte prepared in step (1), the amount of dimethyl phenyl phosphate is 0.5% of the mass of the common electrolyte; obtain a high-voltage lithium-ion battery functional electrolyte.

Embodiment 2

[0048] (1) cyclic carbonate solvent ethylene carbonate (EC) and linear carbonate solvent dimethyl carbonate (DMC) are mixed according to mass ratio EC:DMC=1:3, and adopt Molecular sieve, calcium hydride, and lithium hydride are purified to remove impurities and water to obtain a mixed solvent; the conductive lithium salt LiPF 6 Dissolve in a mixed solvent of ethylene carbonate and dimethyl carbonate, stir evenly to obtain a common electrolyte; among them, the conductive lithium salt LiPF 6 The final concentration in ordinary electrolyte is 0.8mol / L;

[0049] (2) Add dimethyl phenyl phosphate to the ordinary electrolyte prepared in step (1), the amount of dimethyl phenyl phosphate is 0.1% of the mass of the ordinary electrolyte; obtain a high-voltage lithium-ion battery functional electrolyte.

Embodiment 3

[0051] (1) cyclic carbonate solvent ethylene carbonate (EC) and linear carbonate solvent ethyl methyl carbonate (EMC) are mixed according to mass ratio EC:EMC=1:2, and adopt Molecular sieve, calcium hydride, and lithium hydride are purified to remove impurities and water to obtain a mixed solvent; the conductive lithium salt LiSO 3 CF 3 Dissolve in a mixed solvent of ethylene carbonate and dimethyl carbonate, stir evenly to obtain a common electrolyte; among them, the conductive lithium salt LiSO 3 CF 3 The final concentration in ordinary electrolyte is 1.0mol / L;

[0052] (2) Add dimethyl phenyl phosphate to the common electrolyte prepared in step (1), the amount of dimethyl phenyl phosphate is 1% of the mass of the common electrolyte; obtain a high-voltage lithium-ion battery functional electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com