Method for preparing oxygen precipitation electrode based on three-dimensional porous graphene

An oxygen evolution electrode, three-dimensional porous technology, applied in electrodes, battery electrodes, circuits, etc., can solve the problems of hindering the commercial development of metal-air batteries, high oxygen evolution overpotential, and expensive electrodes, and achieve excellent oxygen evolution catalysis. The performance, the preparation method is simple, and the price is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the oxygen evolution electrode based on three-dimensional porous graphene of the present embodiment comprises the following steps:

[0028] 1) Use concentrated sulfuric acid, sodium nitrate and potassium permanganate to oxidize graphite powder to prepare graphite oxide;

[0029] 2) Dry the graphite oxide prepared in step 1) in vacuum at 80°C for 20 hours;

[0030] 3) Grinding the dried graphite oxide obtained in step 2), and then heat-treating at 100°C for 12 hours under vacuum;

[0031] 4) The graphite oxide in step 3) is rapidly heated to 200°C at a rate of 2°C / s under a vacuum of about 0.0088Pa and kept for 10min. The obtained product is an oxygen evolution electrode based on three-dimensional porous graphene .

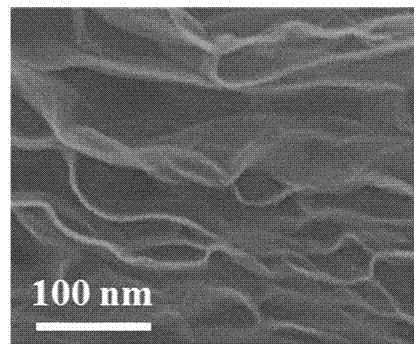

[0032] figure 1 The scanning electron microscope image of the three-dimensional porous graphene electrode prepared for Example 1; three-dimensional graphene with a porous structure can be clearly seen from the figure.

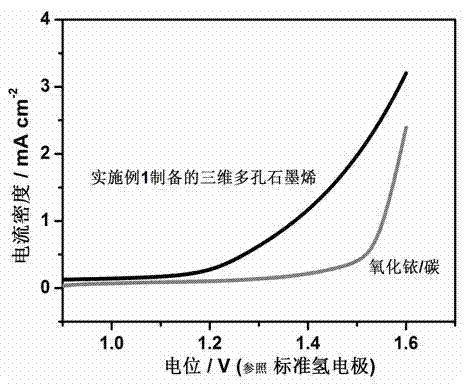

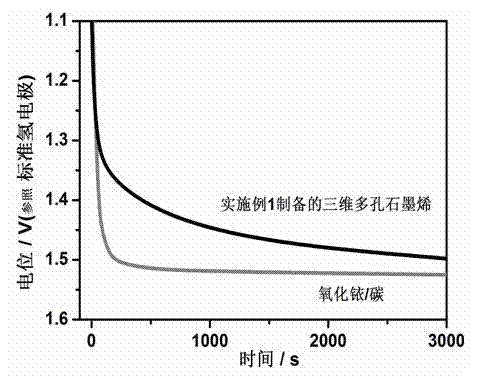

[0033] ...

Embodiment 2

[0037] The preparation method of the oxygen evolution electrode based on three-dimensional porous graphene of the present embodiment comprises the following steps:

[0038] 1) Use concentrated sulfuric acid, sodium nitrate and potassium permanganate to oxidize graphite powder to prepare graphite oxide;

[0039] 2) The graphite oxide prepared in step 1) was vacuum-dried at 60°C for 24 hours;

[0040] 3) Grinding the dried graphite oxide obtained in step 2), and then heat-treating at 80°C for 16h under vacuum;

[0041] 4) The graphite oxide in step 3) is rapidly heated to 180°C at a rate of 3°C / s under a vacuum of about 0.012Pa and kept for 30min. The obtained product is an oxygen evolution electrode based on three-dimensional porous graphene .

[0042] Figure 4 The scanning electron microscope image of the three-dimensional porous graphene electrode prepared for Example 2; three-dimensional graphene with a porous structure can be clearly seen from the figure.

[0043] Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com