Biomass chain boiler

A chain boiler, biomass technology, applied in the combustion method, combustion chamber, combustion of solid fuel and other directions, can solve the problems of inconvenient use of fuel, decrease in output and working medium parameters, low combustion efficiency, etc. Loss, improve the utilization of heat, improve the effect of combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

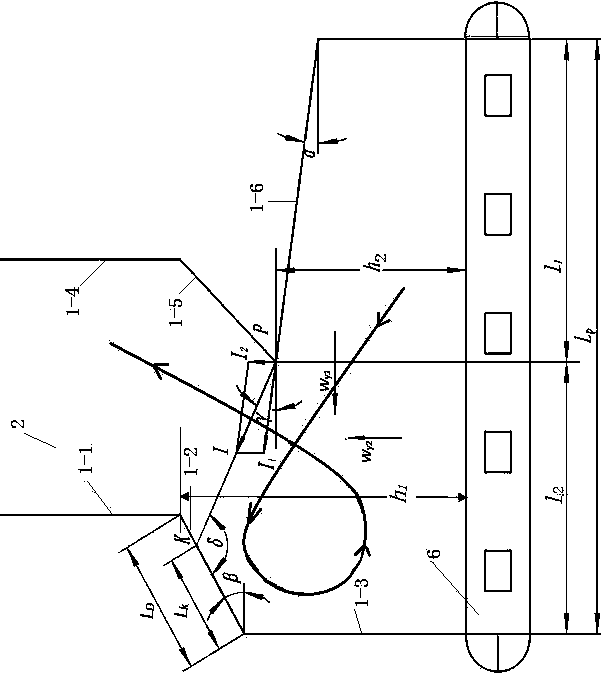

[0027] Depend on Figure 1-Figure 4 The biomass chain boiler shown includes a furnace body 8 provided with a feed inlet. The feed inlet is located at the bottom of the front end of the furnace body 8 . .

[0028] The body of furnace 8 is provided with an upper drum 4, a lower drum 5, a furnace 2, an ember chamber 3, a front arch, a rear arch and a chain grate 6, wherein the upper drum 4, the lower drum 5 and the chain grate 6 are all To extend horizontally back and forth, the front end of the upper drum 4 extends to the front side of the front end of the lower drum 5, the upper drum 4 and the lower drum 5 are connected by a convection tube bundle 9 and the burnout chamber is formed between the two, Of course, the convection tube bundle 9 is also located in the burnout chamber 3, and the furnace 2 is located at the lower side of the front portion of the upper drum 4 and at the front side of the combustion chamber, and the furnace 2 communicates with the combustion chamber. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com