Method for designing two-peak cam with waste gas recycling function of diesel engine

A technology of exhaust gas recirculation and diesel engine, applied in valve details, valve drive devices, etc., can solve problems such as unreported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0143] The present invention is described in detail below in conjunction with accompanying drawing and embodiment, but present embodiment can not be used for limiting the present invention, and every similar method and similar variation thereof that adopt the present invention all should be included in the protection scope of the present invention.

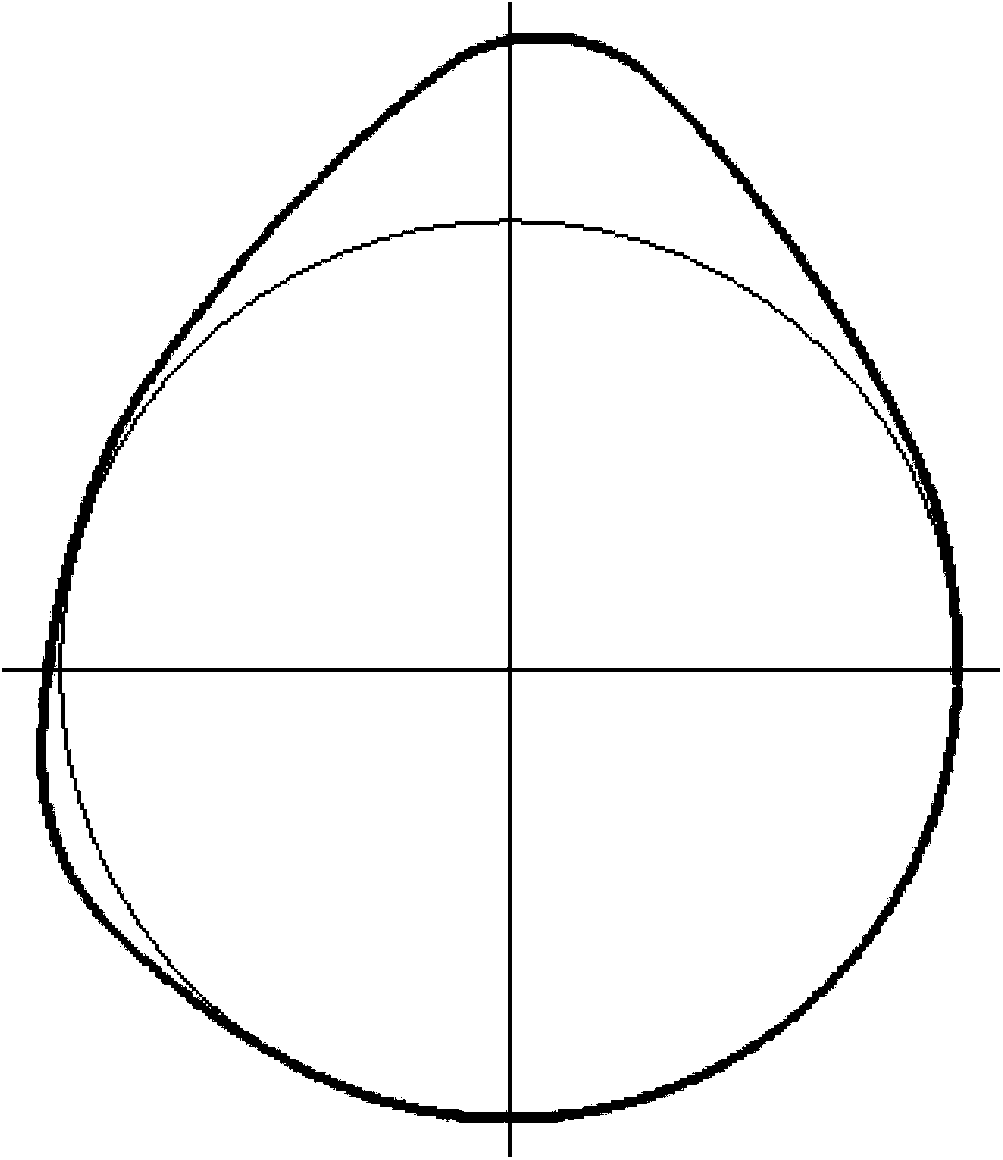

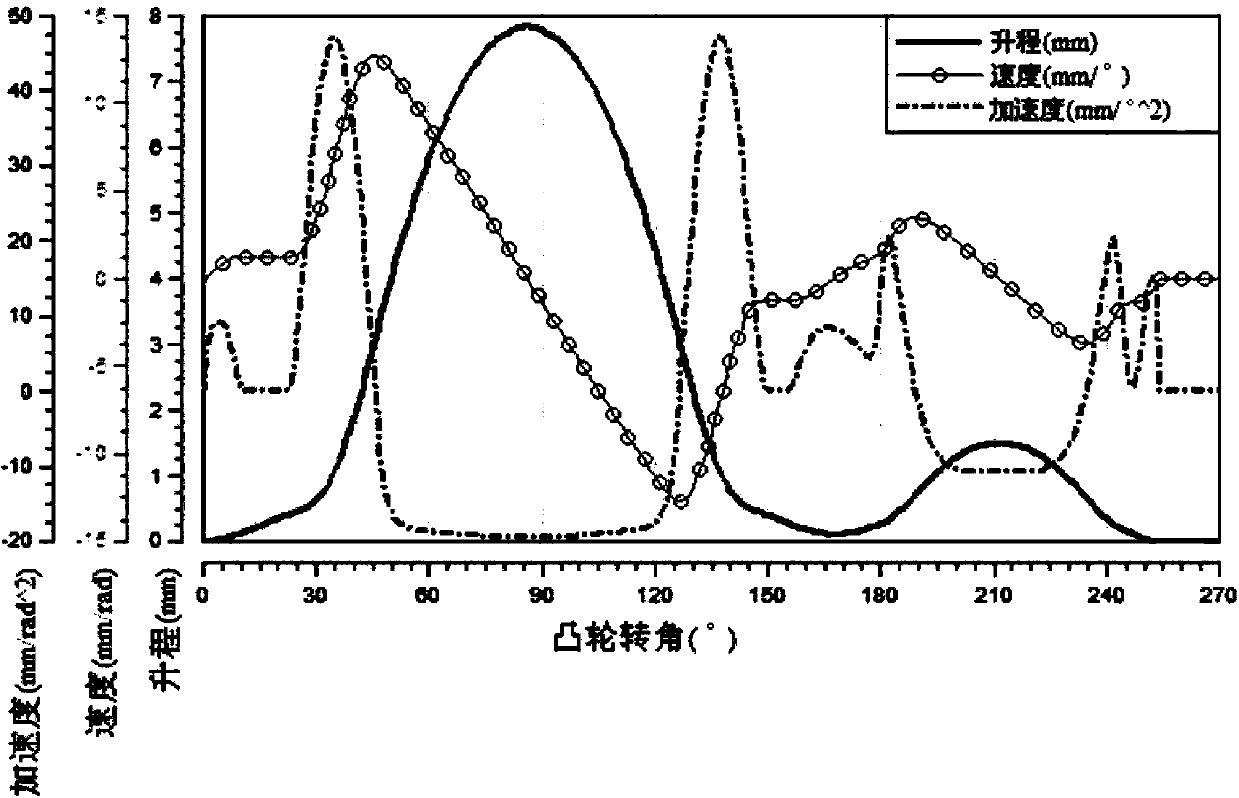

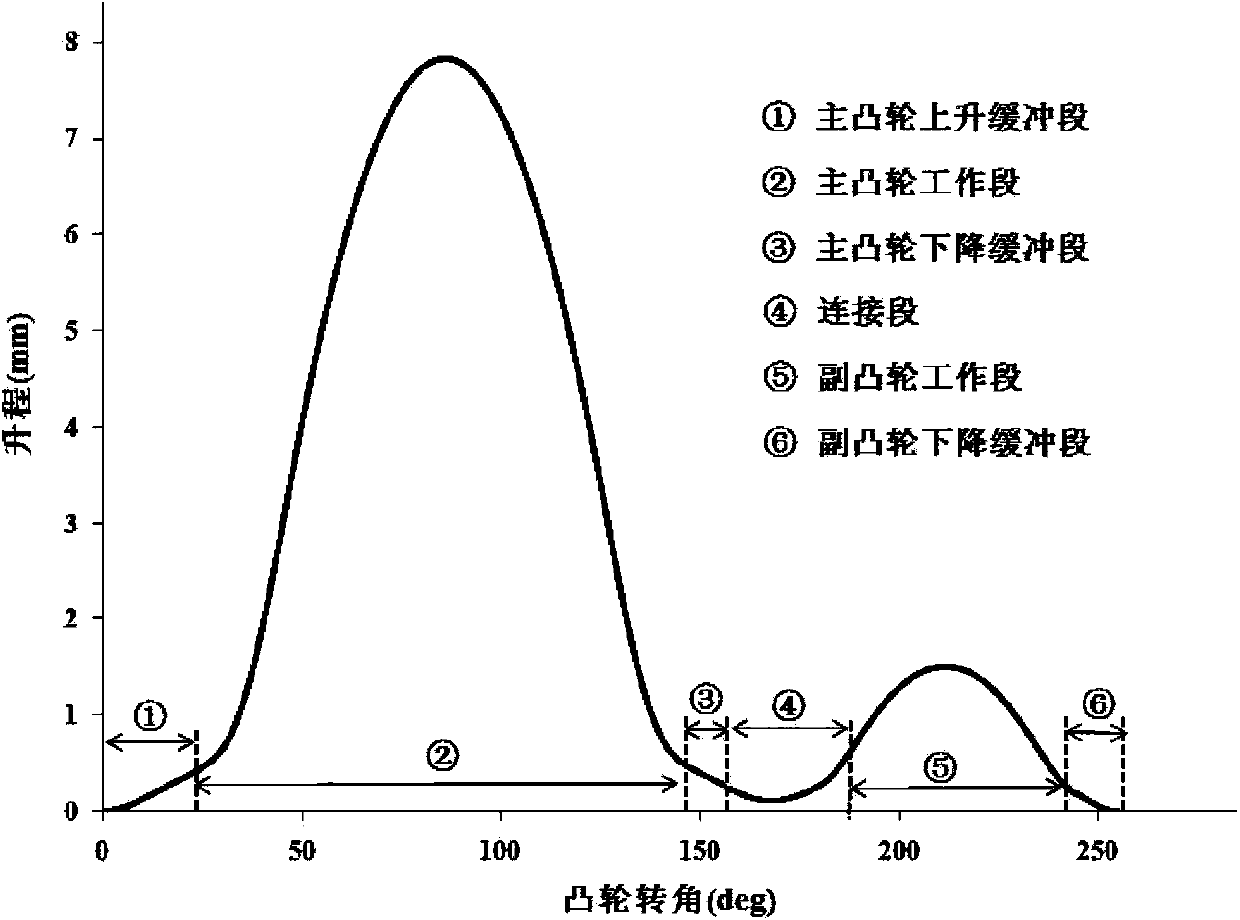

[0144] Example of bimodal cam profile design with diesel exhaust gas recirculation:

[0145] The parameters of the initial conditions of profile design are shown in Table 1.

[0146] Table 1 Type Line Design Parameters

[0147]

[0148] In order to simplify the calculation, when calculating the profile of each section, the starting point of the cam rotation angle is set to zero, and finally the result can be translated to obtain the profile of the entire double-peak cam.

[0149] 1. Calculation of the main buffer segment

[0150] From the initial conditions:

[0151] alpha 1 = 24°

[0152] h 1 =0.438453mm

[0153] v 1 =...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com