Distributing mechanism for roller press and high pressure roller mill

A technology of high-pressure roller mill and material distribution mechanism, which is applied in the direction of grain processing, etc., can solve the problems of poor rolling quality of the end cake, failure to meet the feeding requirements, insufficient extrusion pressure and material extrusion, etc., to achieve Improve the extrusion effect, reliable performance, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

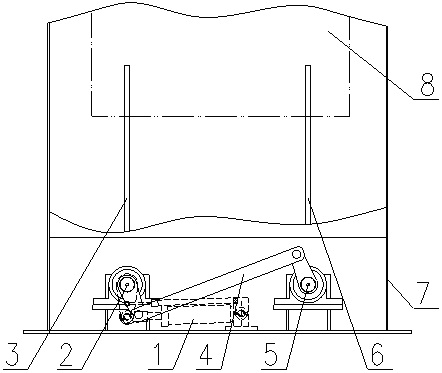

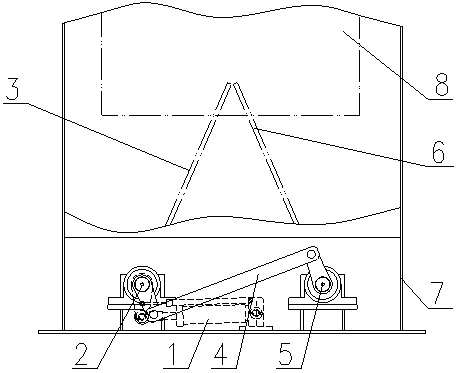

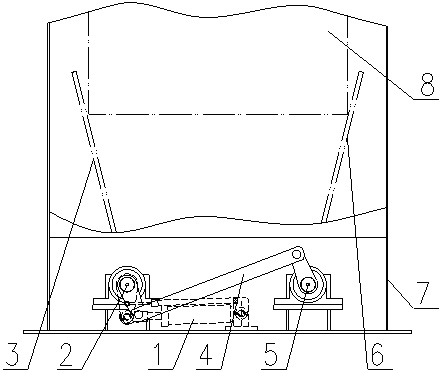

[0020] Such as Figure 1 to Figure 4 As shown, a material distributing mechanism for a roller press and a high-pressure roller mill, including a drive device 1 installed under the squeeze roller 8, a transmission shaft 2, a material distribution plate 3, a connecting rod 4, and a transmission shaft 2 5 And distribution plate two 6, described driving device 1 drives transmission shaft one 2 to rotate, and the connecting rod 4 that connects transmission shaft one 2, transmission shaft two 5 drives transmission shaft two 5 reverse rotations; Said material distribution plate one 3. Distributing plates 2 and 6 are respectively fixed on transmission shaft 1 and transmission shaft 2 5 and swing left and right along the width direction of extrusion roller 8 as they rotate. The two swing directions are opposite and the sum of the swing range covers the entire extrusion Roll 8 roll wide range. As a preferred mode, as shown in this embodiment, in the initial state, the first 3 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com