Preparation method of gadolinium oxide-coated ferroferric oxide magnetic fluorescent nano hollow spheres

A technology of ferroferric oxide and fluorescent nanometers, which is applied in the preparation of microspheres, chemical instruments and methods, and the magnetism of inorganic materials. It can solve the problems of particle aggregation and other problems, and achieve the effects of good repeatability, large specific surface area, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] ① Take 1.5g of nano-microspheres with a particle size of 500nm of silica, add 10ml of distilled water, and sonicate to a uniform colloidal solution.

[0026] ②Weigh 0.268g of ferric nitrate hexahydrate and 0.290g of urea respectively, mix them together, dissolve them in 20ml of distilled water, and add them into a three-necked flask.

[0027] ③Put the mixed solution of ① into the three-neck flask of ②, and add 70ml of distilled water to form a red homogeneous colloidal solution.

[0028] ④Put the three-necked flask into a constant temperature water tank, stir, adjust the temperature of the constant temperature water bath at 95°C, and keep stirring for 4 hours after the system temperature reaches 95°C.

[0029] ⑤ Centrifuge the above mixed solution, wash with double distilled water, and then centrifuge to obtain a reddish-brown solid precipitate.

[0030] ⑥ The above steps are a complete process for one-time coating of particles, and the coating of rare earth element ga...

Embodiment 2

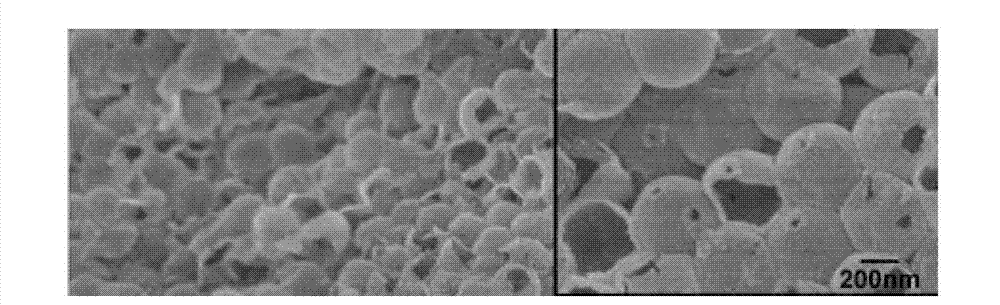

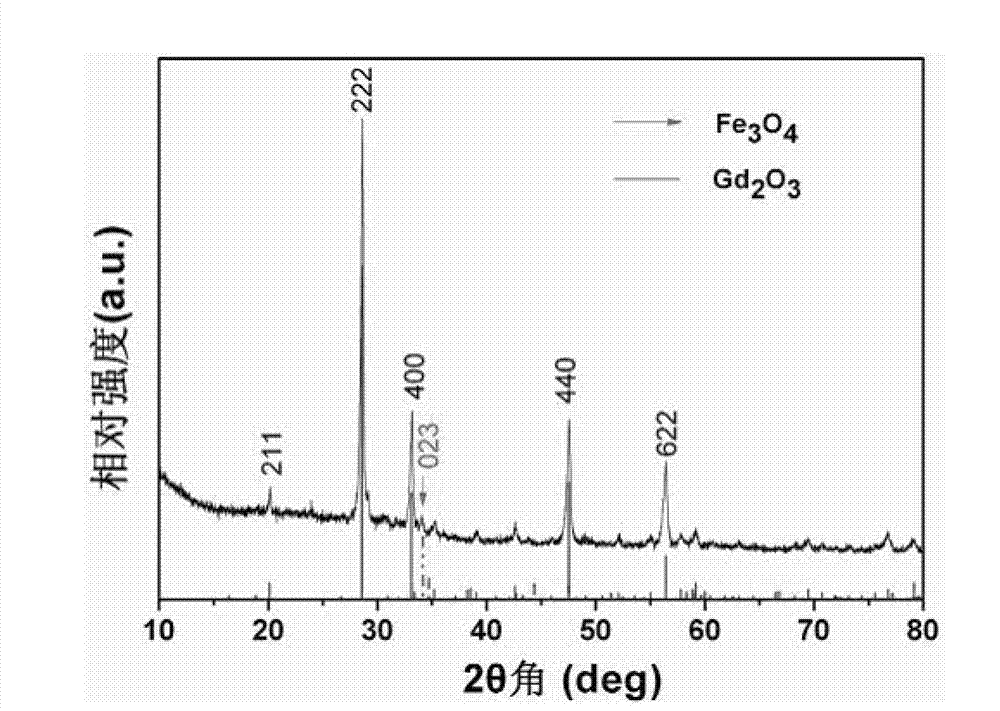

[0037] The proportioning in the method of above-mentioned embodiment 1 is constant, uses silicon dioxide particle diameter 180nm as inner core, carries out coating, then etches away inner core with sodium hydroxide 0.5mol / L, reduces with hydrogen, and reduction temperature remains at 450 ° C, other conditions are the same as in Example 1, Fe 3 o 4 Gd 2 o 3 nano hollow spheres. From Figure 4 It can be seen from the SEM that the overall coating is relatively uniform, monodisperse and regular.

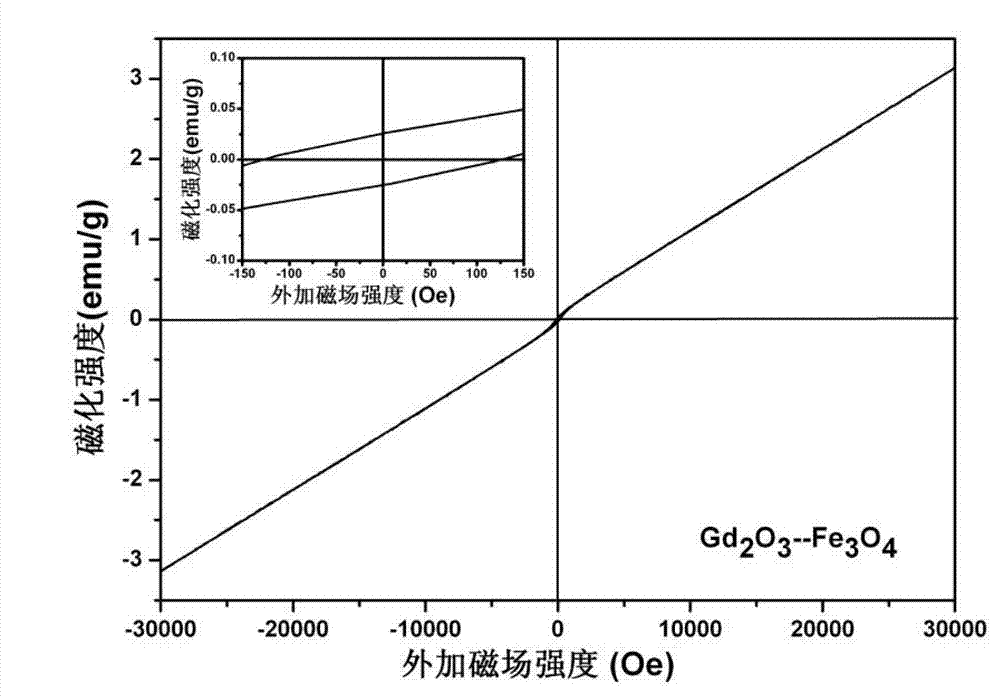

[0038] In conclusion, the present invention reports a method using a hard template method, using silica with different inner diameters as a template, and synthesizing metal Fe with particle inner diameters of about 500nm and 180nm through a hydrolysis process. 3 o 4 Gd 2 o 3 nano hollow spheres. We adopt the wet injection process and reduce it to obtain metallic Fe 3 o 4 Gd 2 o 3 nano hollow spheres.

[0039] The hollow spheres obtained in this patent have a relatively larg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com