Porous cordierite block preparation method

A technology of cordierite and block, which is applied in the field of preparation of porous cordierite block by epoxide-controlled sol-gel with phase separation method, which can solve complex processes such as co-hydrolysis sol-gel transition and phase separation , difficult to control and other problems, to achieve the effect of controlling the aperture size, low equipment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, a preparation method of a porous cordierite block, first prepare the main raw material according to the following ratio: with 0.80g of magnesium chloride hexahydrate (MgCl 2 ·6H 2 O) as the source of magnesium, with 2.0 g of aluminum chloride hexahydrate (AlCl 3 ·6H 2 O) as the aluminum source, 0.96ml of orthomethyl silicate (TMOS) as the silicon source, 1.5g of polyacrylamide (PAAm, with an average molecular weight of 10000) as the phase separation inducer, and 0.6ml of propylene oxide ( PO) is the gel accelerator; the following steps are performed in sequence:

[0028] 1) At room temperature, first dissolve 0.80g of magnesium chloride hexahydrate, 2.0g of aluminum chloride hexahydrate and 1.5g of polyacrylamide in a solvent consisting of 3.0ml of deionized water and 2.8ml of absolute ethanol, and then Slowly add 0.96ml of methyl orthosilicate dropwise under stirring (the dropping time is about 2 minutes); after the dropwise addition is completed, plac...

Embodiment 2

[0034] Embodiment 2, a kind of preparation method of porous cordierite block,

[0035] Change the heat treatment temperature in Step 5) of Example 1 from 800°C to 1300°C, and the rest are the same as in Example 1.

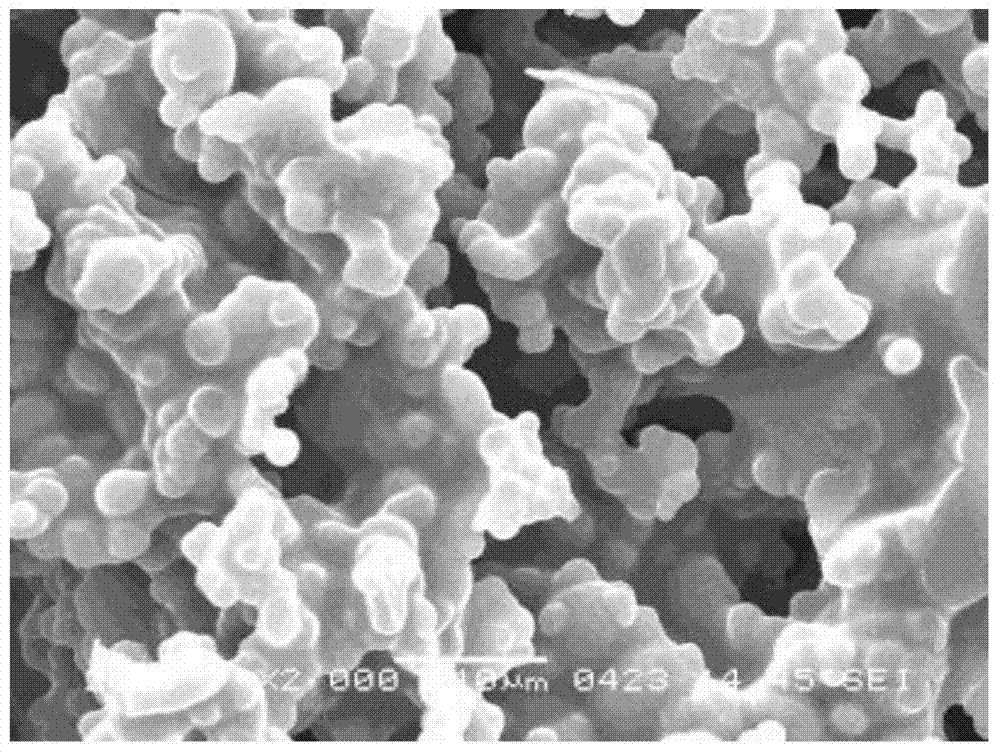

[0036] The prepared porous cordierite block remains intact, has no cracks on the surface of the block, and has only a small amount of shrinkage; the crystallinity is good, and the phase is a single α-type cordierite. The interior of the porous cordierite block has a co-continuous macroporous structure and a complete framework (see figure 1 ), the average pore diameter of macropores is 5 microns, and the apparent density of the block is about 0.82g / cm 3 , the calculated relative density is 32%, and the porosity is 54%. The N of the porous cordierite block 2The adsorption-desorption curve is H3 type, indicating that the block has a certain number of slit-like mesopores due to its skeleton structure, so the cordierite block has a hierarchical porous structure.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com