Sludge filtering machine

A filter and sludge technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve problems such as difficulty, environmental pollution, and mud overflow, and achieve the effect of reducing filtration cost, high filtration efficiency, and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

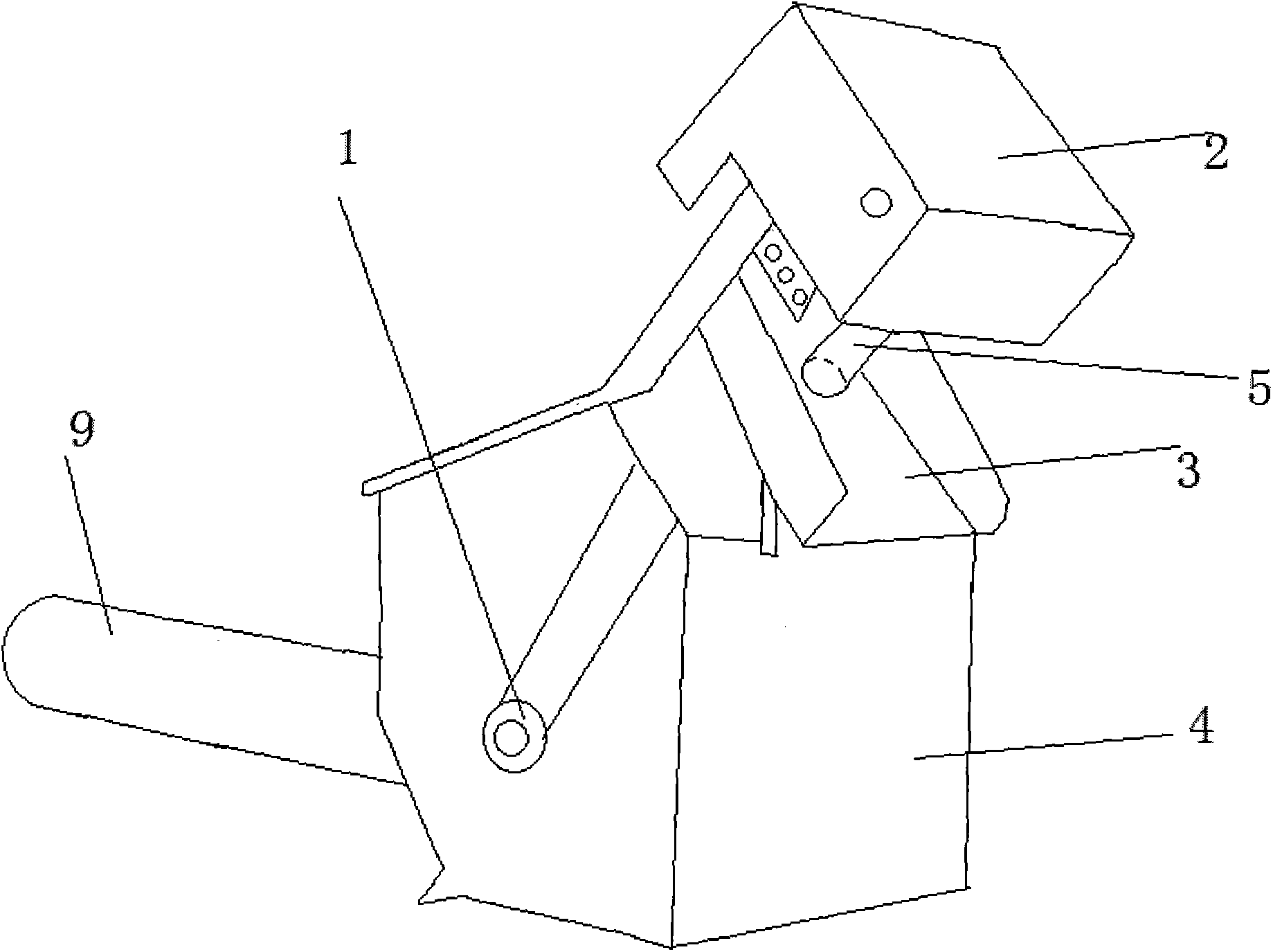

[0021] A sludge filter, such as Figure 1-2 As shown, it includes a drive motor 1, an electric control box 2, a discharge port 3, a housing 4, a drive shaft 5, a cone 6 and a filter shower head 7, the drive motor 1 is arranged in the housing 4, and is connected to the drive shaft 5, The drive shaft 5 is connected with the electric control box 2, the bottom of the electric control box 2 is provided with a discharge port 3, the end of the drive shaft 5 is provided with a cone 6, and the entrance of the cone 6 is connected with the filter shower head 7. Filtration shower head 7 is also connected with pipeline 9.

[0022] The cone 6 is composed of an upper vertebral body 8 and a lower vertebral body 10 , and the upper vertebral body 8 is provided with a helical blade 11 and a blocking ring 12 . The blocking ring 12 blocks the upward movement of the sludge and guides the sludge to flow to the discharge port 3 .

[0023] The filter shower head 7 is made of a stainless steel tube w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com