Injection molding machine automatic feeding device

An automatic material feeding and injection molding machine technology, applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of high production cost and maintenance cost, complex structure of automatic material suction machine, obstructed air flow, etc., and achieve simple structure , low maintenance cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

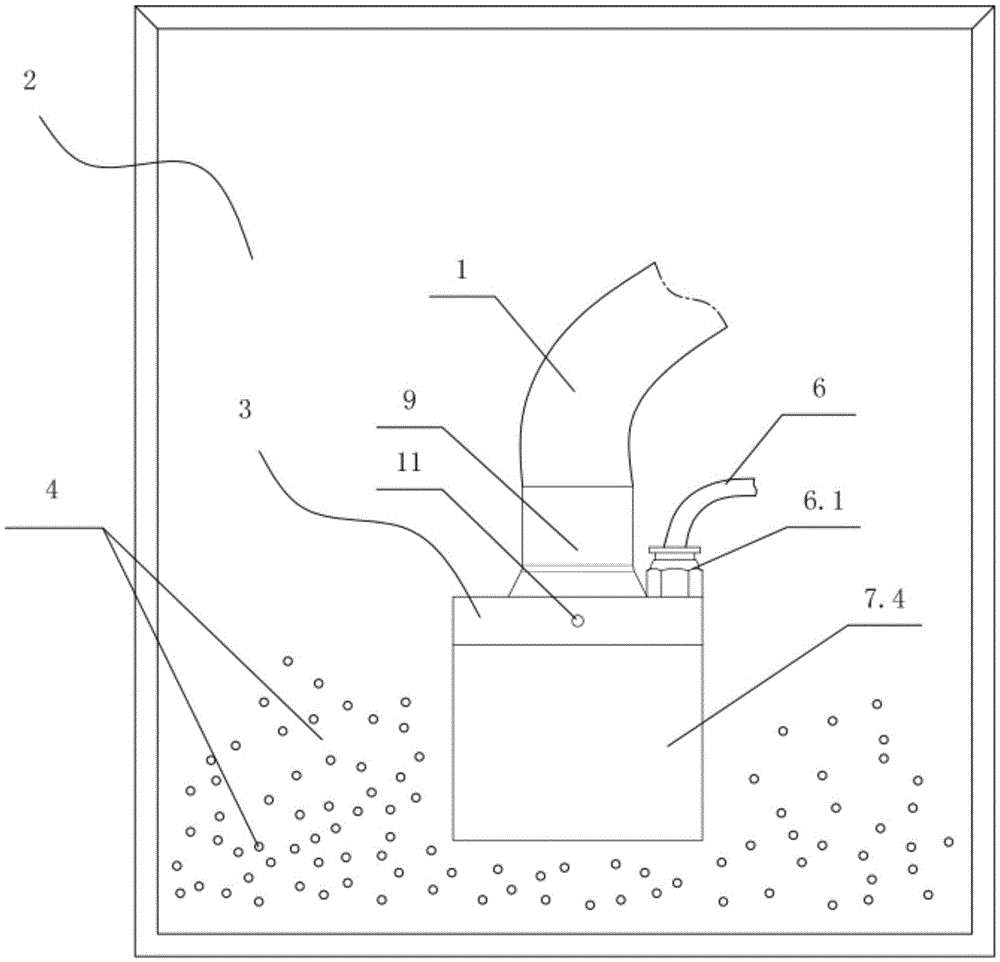

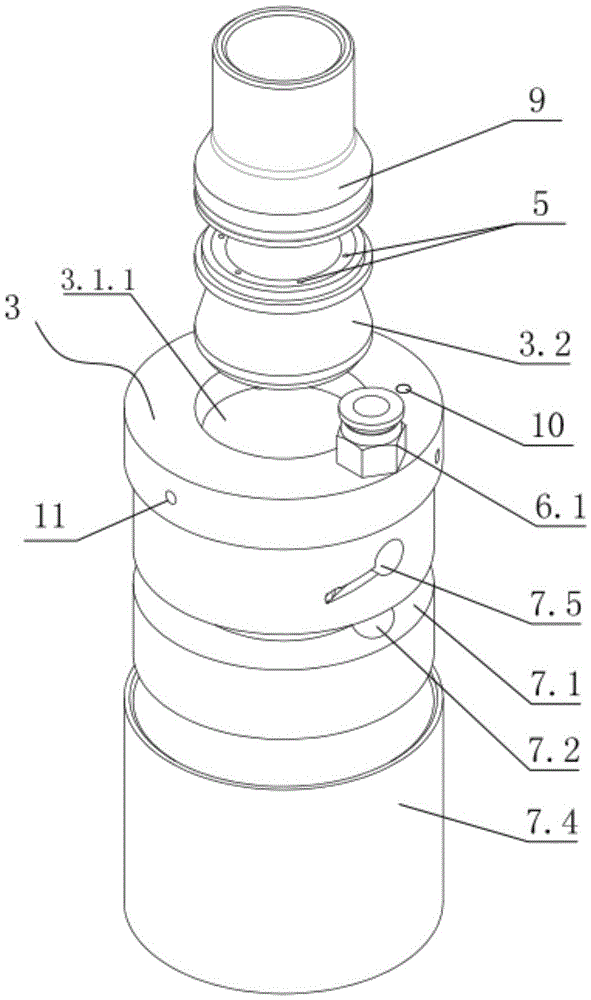

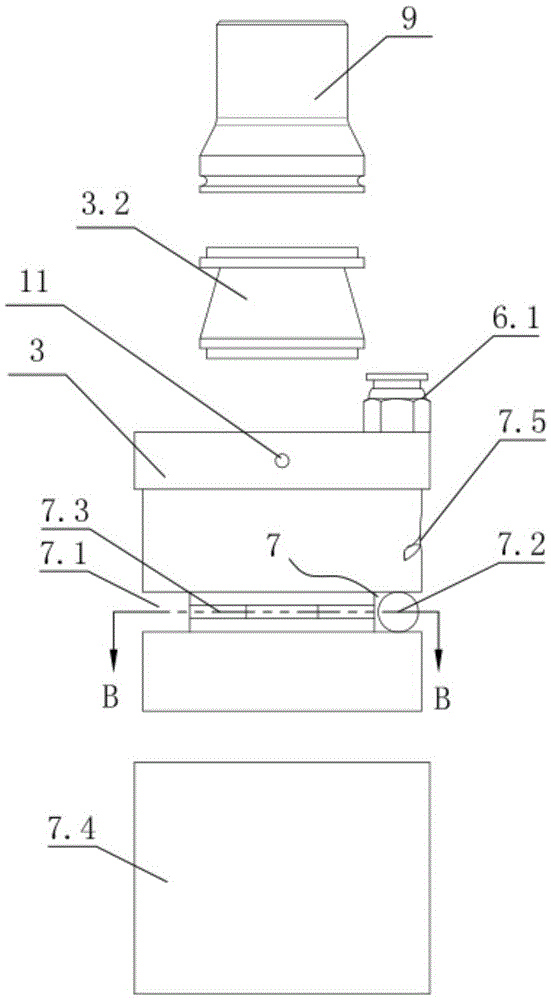

[0024] Such as figure 1 As shown, the present invention provides an automatic feeding device for an injection molding machine, which includes a feeding pipe 1 , one end of the feeding pipe 1 communicates with the injection molding machine, and the other end is placed in a storage barrel 2 . The communication with the injection molding machine referred to above can be directly connected with the mold cavity of the injection molding machine, and can also be connected with a container for temporarily storing plastic particles 4 such as a discharge barrel or a funnel on the injection molding machine. As the invention attached Figure 7 As shown, one end of the feeding pipe 1 communicates with the injection molding machine feeding cylinder 13, and the lower end of the injection molding machine feeding cylinder 13 shown communicates with the injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com