Al-V-Cr-Fe-Ti intermediate alloy and preparation method thereof

A technology of aluminum vanadium chromium iron and master alloy, which is applied in the field of aluminum vanadium chromium ferrotitanium master alloy and its preparation, can solve the problems of difficult production process of titanium alloy, unstable product performance, complicated production process, etc., and shorten the production process , convenient preparation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

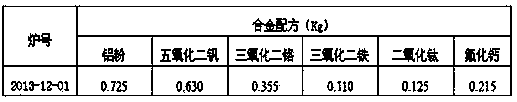

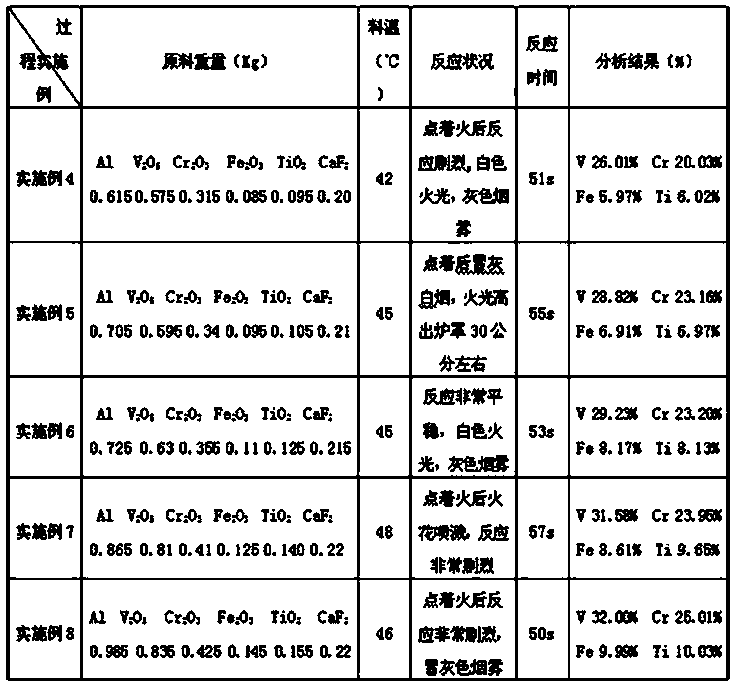

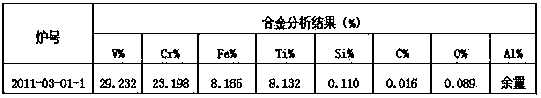

Embodiment 1

[0017] The weight percent alloy composition of the aluminum-vanadium-chromium-iron-titanium master alloy is: V: 26.0%%, Cr: 20.0%, Fe: 6%, Ti: 6%, and Al is the balance. The five-element alloy is used as an intermediate alloy, and is added to sponge titanium and aluminum beans in the form of an alloy package. When using a vacuum consumable furnace to smelt titanium alloys, it is easy to control the magnitude of the current because of the uniform composition of the ingot, which facilitates the preparation of titanium alloys. The degree of alloy segregation is low.

Embodiment 2

[0019] The weight percent alloy composition of the aluminum vanadium chromium iron titanium master alloy is: V: 32.0%, Cr: 25.0%, Fe: 10%, Ti: 10%, and Al is the balance. The five-element alloy is used as an intermediate alloy, and is added to sponge titanium and aluminum beans in the form of an alloy package. When using a vacuum consumable furnace to smelt titanium alloys, it is easy to control the magnitude of the current because of the uniform composition of the ingot, which facilitates the preparation of titanium alloys. The degree of alloy segregation is low.

Embodiment 3

[0021] The weight percent alloy composition of aluminum vanadium chromium iron titanium master alloy is: V: 30.0%, Cr: 22.0%%, Fe: 8%8, Ti: 8%, Al is the balance. The five-element alloy is used as an intermediate alloy, and is added to sponge titanium and aluminum beans in the form of an alloy package. When using a vacuum consumable furnace to smelt titanium alloys, it is easy to control the magnitude of the current because of the uniform composition of the ingot, which facilitates the preparation of titanium alloys. The degree of alloy segregation is low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com