Granular Schwertmannite and its preparation method and use

A Shishi mineral, granular technology, applied in the field of granular Shishi mineral and its preparation, can solve the problems of difficult recovery, limited application, long synthesis cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation of embodiment 1 granular Shi's minerals

[0034] (1) Weigh the biogenic Schwartz mineral powder 20 prepared according to the method disclosed in ZL200510094428.8 Example 1 g , join in the Erlenmeyer flask that fills the 200mL NaOH solution that pH is 12;

[0035] (2) Place the above Erlenmeyer flask in a shaker at 25°C and 180rpm for 12h;

[0036] (3) Vacuum filter the above solution and wash it with water for 3-5 times until the effluent is nearly neutral, then dry it.

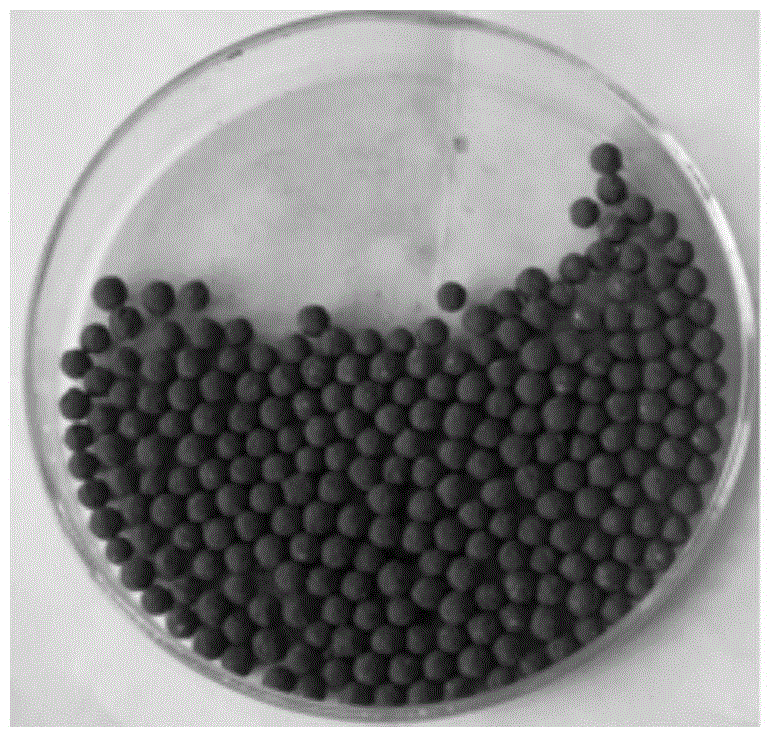

[0037] (4) Adhere 1g of the above-mentioned modified powdered Schwartz minerals to the surface of 250g of zeolite particles with a particle size of about 4mm with glass glue, and dry them in an oven at 50°C to obtain granular Schwartz minerals, small The particle density is 1.195g / cm 3 , and store it in a dry box for later use.

[0038] (5) In order to observe the anti-breaking ability of the particles, add 100mLH 2 O was placed in a 250mL Erlenmeyer flask and shaken in a shaker at...

Embodiment 2

[0040] The preparation of embodiment 2 granular Shi's mineral adsorption columns

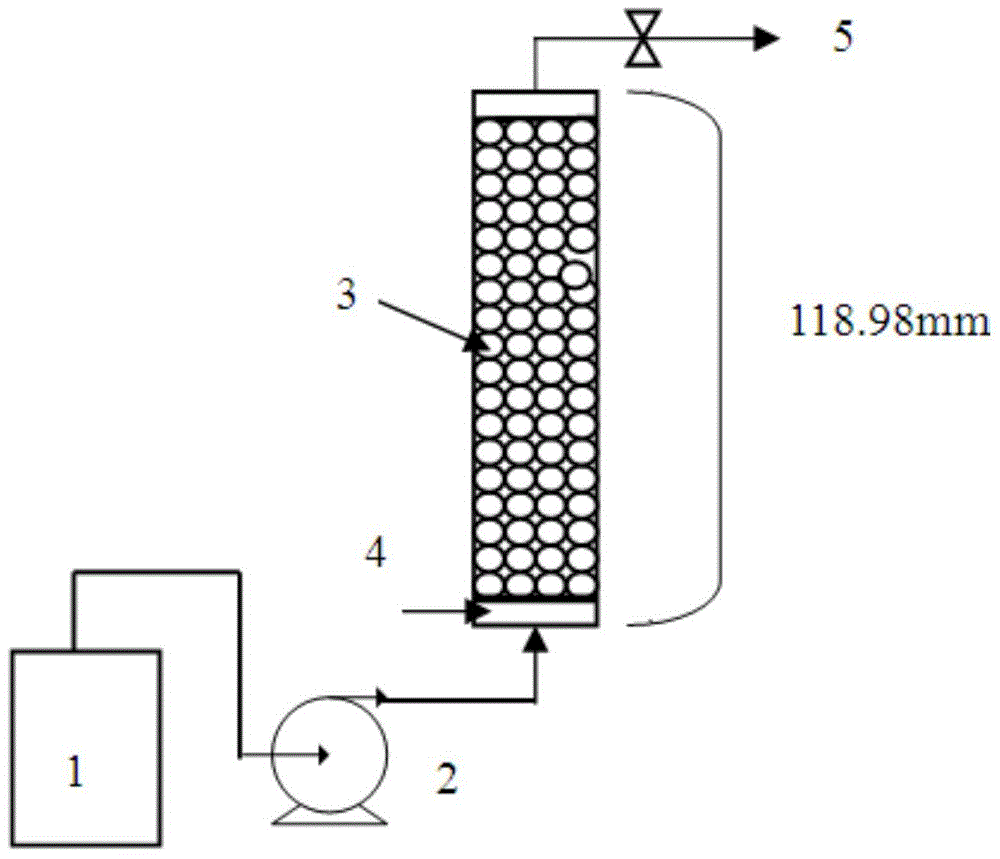

[0041] Take by weighing 44g of granular Shi's minerals (prepared in Example 1) and fill them with an internal diameter of 29.3mm and a column height of 118.98mm in a plexiglass column. The glass column is filled with glass fibers of 5mm up and down. The actual adsorbent height is 108mm, and the packing density 0.604g / cm 3 , with a porosity of 49.4%, artificially prepared arsenic-containing groundwater through a peristaltic pump (LDB-M electronic peristaltic pump) at a certain influent flow rate from bottom to top through the adsorption column. figure 2 It is a schematic diagram of the adsorption column test device.

Embodiment 3

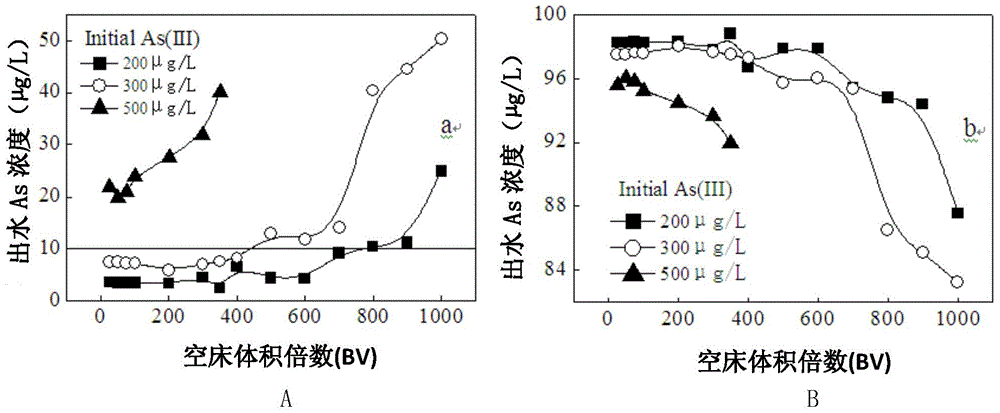

[0042] Example 3 The Adsorption and Removal of As(III) and As(V) in Simulated Water by Granular Schwartz Mineral Adsorption Column

[0043] 3.1 Test method

[0044] 3.1.1 Preparation of As(III) and As(V) solutions

[0045] Analytical pure As dried at 110°C for 2 h 2 o 3 Dissolve 0.6595g in 20mL NaOH solution with a mass fraction of 40%, moderately dilute with ultrapure water (>18MΩcm), then adjust the pH of the solution to 7.0 with superior pure hydrochloric acid, and dilute to 500mL, this stock solution As(III) The concentration is 1000mg / L, and it is stored in a refrigerator at 4°C, protected from light.

[0046] Accurately weigh 1.2015g KH 2 AsO 4 In a beaker, add 100mL of ultrapure water (>18MΩcm), dilute HCl to adjust to pH=7.0, and set the volume to 500mL. The As(V) concentration of this stock solution is 1000mg / L, and store in a refrigerator at 4°C in the dark.

[0047] 3.1.2 Influence of the concentration of As(III) in the influent on the removal of arsenic by th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com