Engineering Applicability Evaluation Method of Fiber Bragg Grating Strain Sensor

A strain sensor and fiber grating technology, applied in the field of measurement, can solve the problems of no engineering applicability, staying in the laboratory stage, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

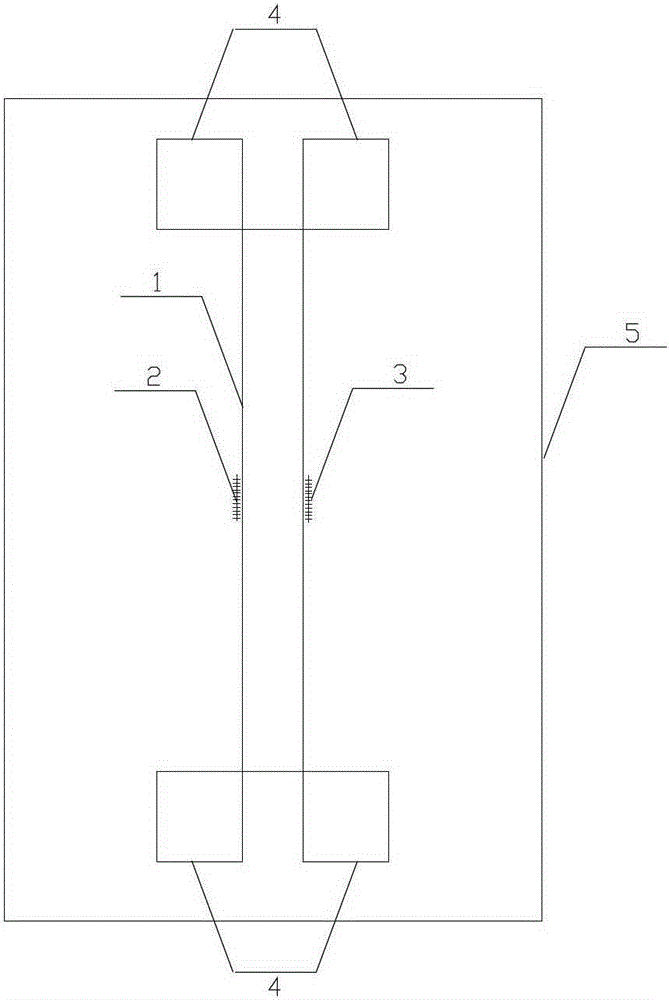

Image

Examples

Embodiment

[0055] Embodiment: the present invention is described in further detail with certain example below;

[0056] Step 1.1: When the test condition is normal temperature, the preparation steps for the test are: provide a tensile / compression test piece, determine the position where the fiber grating strain sensor sheet is pasted on the tension / compression test piece, and paste the corresponding position Resistance strain gauge, install the tensile / compression test piece that has pasted the fiber grating strain sensor and the resistance strain gauge on the material mechanical performance testing machine, adjust the holding position of the tensile / compression test piece on the Instran8801 material mechanical performance testing machine, so that the tensile Stretch test pieces are evenly stressed; connect the fiber grating strain sensor to the fiber grating strain measurement system SM130-700; connect the resistance strain gauge to the resistance strain measurement system ST-16;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com