Mixed adsorbent, grease and preparation method thereof

A kind of adsorbent and oil technology, which is applied in the direction of oil/fat refining, chemical instruments and methods, non-effective components of oil/fat/wax, etc. It can solve the problems of low light absorption value, reduced anisidine value, low anisidine value of oil, etc. , to achieve the effect of reducing absorbance, reducing content and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0106] Before the preparation method described in the present invention, the above-mentioned pretreatment steps may not be included, because the refining steps described in the present invention can also effectively remove by-products such as free fatty acids, peroxides, unsaponifiables, metal ions, arsenic salts, etc. product or impurity. Therefore, it is only necessary to carry out the refining treatment steps of various raw oils and fats, and the obtained oils can meet various requirements of medicinal oils, or achieve the purpose of effectively reducing the content of chloropropanol esters.

[0107] The oil preparation method disclosed in the present invention includes the above-mentioned refining treatment.

[0108] Post-processing

[0109] The post-treatment described in the present invention includes desolvation and other conventional post-treatments.

[0110] Precipitation refers to the solvent removal of the product in the product, which is a routine method for thos...

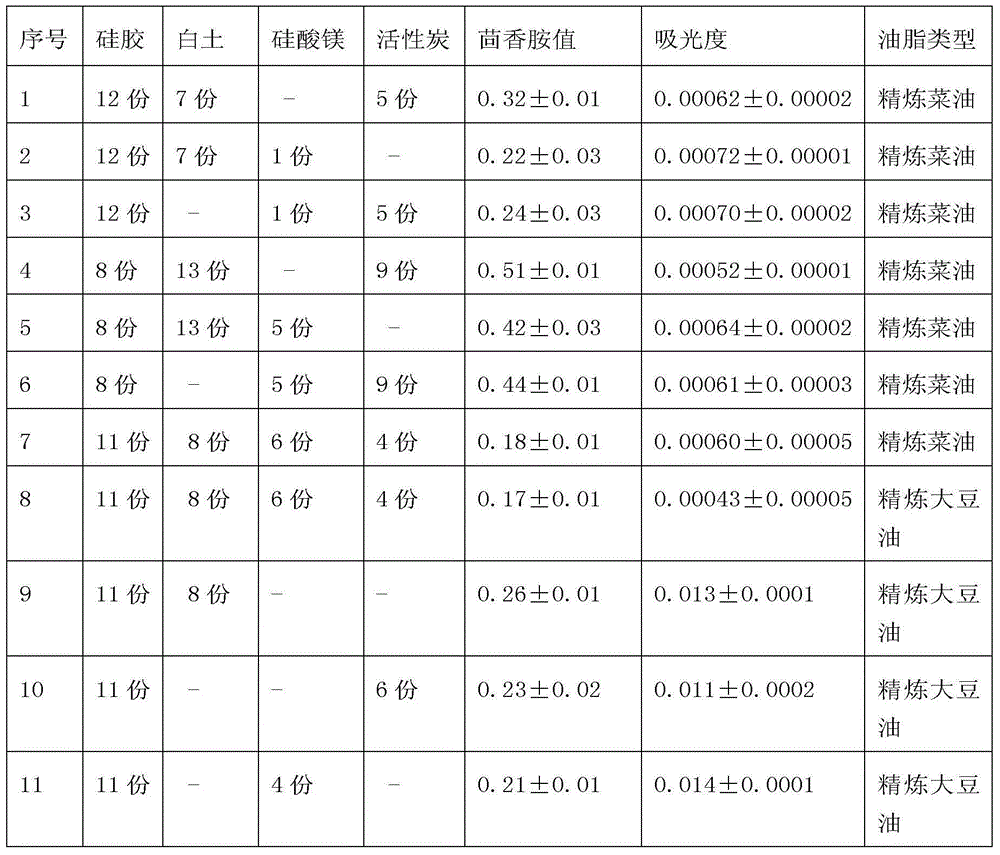

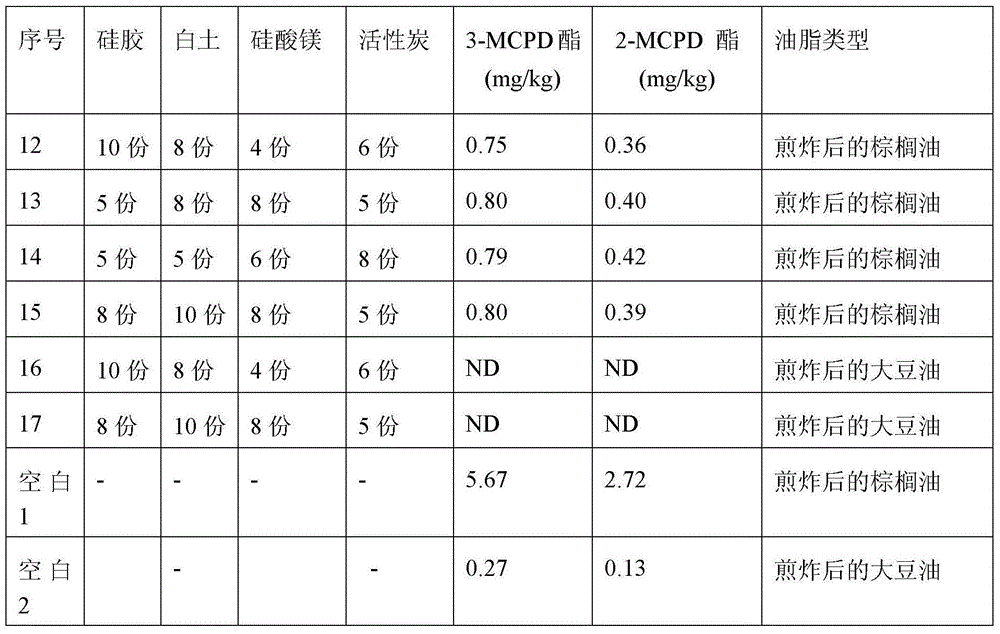

Embodiment 12-17

[0197] In Examples 12-17, according to the following operations, the raw materials are mixed uniformly as fillers, and the following operations are carried out:

[0198] 1. The results of blank 1 and blank 2 are shown in Table 4 according to the oil used for frying without using adsorbent;

[0199] 2. Weigh 5-10 parts of 60-400 mesh silica gel, 5-10 parts of clay, 5-8 parts of activated carbon, and 4-8 parts of magnesium silicate, mix them evenly, and pack them in a glass chromatography column;

[0200] 3. Take 10 parts of oil used for frying, mix well with n-hexane as solvent, slowly add to the top of the chromatography column, elute with n-hexane, and protect the whole process with nitrogen; the elution process is controlled at 24°C to 60°C between.

[0201] 3. The eluent is removed from n-hexane with a rotary evaporator at 40°C to obtain grease with low chloropropanol ester content. The details of Examples 12-17 are shown in Table 4.

[0202] Table 4 Content of chloropro...

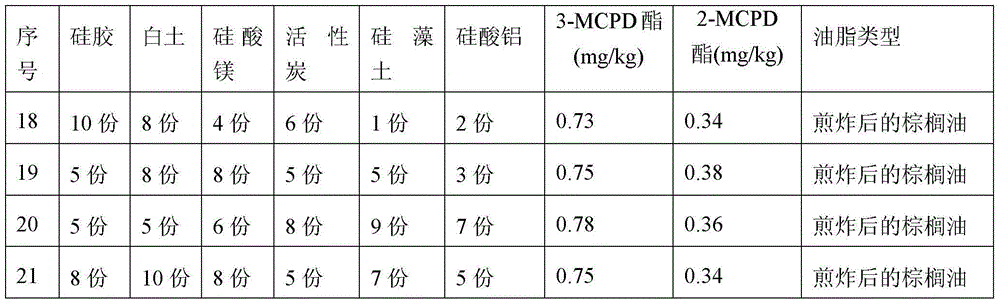

Embodiment 18-21

[0205] In Example 18-21, according to the following operations, the raw materials were mixed uniformly as fillers, and the following operations were performed:

[0206] 1. Weigh 5-10 parts of 60-400 mesh silica gel, 5-10 parts of clay, 5-8 parts of activated carbon, 4-8 parts of magnesium silicate, diatomaceous earth and aluminum silicate, mix well, and fill in glass In the chromatography column;

[0207] 2. Take 10 parts of oil used for frying, use n-hexane as a solvent, stir well, slowly add to the top of the chromatography column, elute with n-hexane, and protect the whole process with nitrogen; the elution process is controlled at 24°C to 60°C between.

[0208] 3. The eluent is removed from n-hexane with a rotary evaporator at 40°C to obtain grease with low chloropropanol ester content. The details of Examples 18-21 are shown in Table 5.

[0209] Table 5 Content of chloropropanol ester in treated oil

[0210]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com