Functional peanut milk and preparation method thereof

A peanut milk, functional technology, applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems of not being able to exert a good health care effect, protein colloid solution sedimentation, protein denaturation, etc., to protect the liver, improve immunity, liquid uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

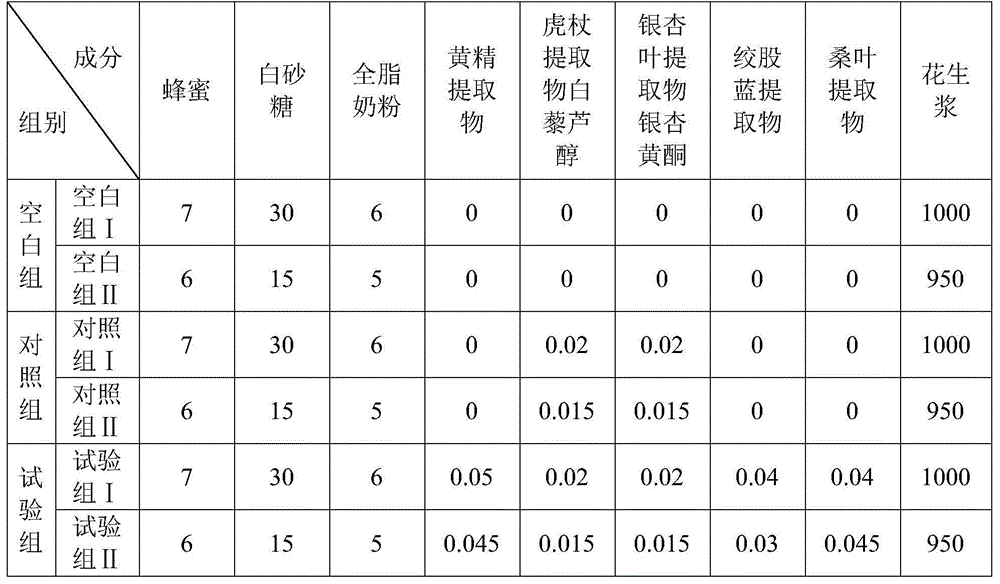

[0041] A functional peanut milk product I is composed of the following raw materials in parts by mass: 5 parts of honey, 20 parts of white sugar, 4 parts of whole milk powder, 1100 parts of peanut pulp, 0.03 parts of Polygonatum extract, resveratrol of Polygonum cuspidatum extract 0.03 parts, Ginkgo biloba extract 0.03 parts Ginkgo flavonoids, Jiaogulan extract 0.06 parts, mulberry leaf extract 0.06 parts;

[0042] The finished product I is prepared by the following steps:

[0043] Step A, prepare peanut pulp

[0044] Dry the peanut kernels at 120°C, remove the seed coat to obtain peeled peanut kernels, grind the peeled peanut kernels, boil them with purified water in a mass ratio of 100:800 for 30 minutes, and filter after cooling. Obtain the peanut pulp;

[0045] Step B, preparation of sealwort extract

[0046] Soak Polygonatum in hot water and extract by ultrasonic extraction, separate the extract with a chromatographic column, then remove the solvent by membrane separat...

Embodiment 2

[0057] A functional peanut milk product II is composed of the following raw materials in parts by mass: 10 parts of honey, 40 parts of white sugar, 8 parts of whole milk powder, 900 parts of peanut pulp, 0.06 parts of Polygonatum extract, resveratrol of Polygonum cuspidatum extract 0.01 part, Ginkgo biloba extract 0.01 part, Ginkgo flavonoids 0.01 part, Jiaogulan extract 0.02 part, mulberry leaf extract 0.02 part;

[0058] The finished product II is made by the following steps:

[0059] Step A. Dry the peanut kernels at 125°C, remove the seed coat to obtain peeled peanut kernels, grind the peeled peanut kernels, boil them with purified water for 30 minutes according to the mass ratio of 100:1000, and cool After filtering, peanut pulp is obtained;

[0060] Step B, preparation of sealwort extract

[0061] Soak Polygonatum in hot water and extract by ultrasonic extraction, separate the extract with a chromatographic column, then remove the solvent by membrane separation, and fi...

Embodiment 3

[0072] A functional peanut milk product III is composed of the following raw materials in parts by mass: 7 parts of honey, 30 parts of white sugar, 6 parts of whole milk powder, 1000 parts of peanut pulp, 0.05 part of Polygonatum extract, resveratrol of Polygonum cuspidatum extract 0.02 parts, Ginkgo biloba extract 0.02 parts, Ginkgo flavonoids 0.02 parts, Jiaogulan extract 0.04 parts, mulberry leaf extract 0.04 parts;

[0073] The finished product III is prepared by the following steps:

[0074] Step A. Dry the peanut kernels at 123°C, remove the seed coat to obtain peeled peanut kernels, grind the peeled peanut kernels, boil them with purified water in a mass ratio of 100:900 for 30 minutes, and cool After filtering, peanut pulp is obtained;

[0075] Step B, preparation of sealwort extract

[0076] Soak Polygonatum in hot water and extract by ultrasonic extraction, separate the extract with a chromatographic column, then remove the solvent by membrane separation, and final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com