Emulsion condiment

A technology of seasoning and emulsification particles, which is applied in the directions of food ingredients as emulsifiers, oil-containing food ingredients, food preparation, etc. Appearance, dehydration inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] 2.1.1. Preparation of emulsified seasoning

[0091] The liquid seasoning of Example 1 was prepared according to the recipe in Table 1 below. That is, the inner water phase and the oil phase in the following Table 1 were emulsified with a homomixer (manufactured by Tokukuki Kagaku Kogyo Co., Ltd., T.K. Automatic Homomixer MA) to prepare a W / O type emulsion. Next, add the external water phase of the following table 1 to the W / O type emulsion, emulsify with a mixer, and then emulsify with a colloid mill to prepare the liquid seasoning of Example 1 (W / O / W type emulsified granules ). The average particle diameter of the immediately prepared liquid seasoning (W / O / W emulsified particles) was measured to be 10 μm using a particle size distribution measuring device (manufactured by Nikkiso Co., Ltd., particle size distribution meter MT3300EXII). In addition, using a microscope (manufactured by Keyence Corporation, digital microscope VHX-600, magnification: 2000 times) to obser...

Embodiment 2

[0107] The emulsified seasoning of Example 2 was prepared by the same method as in Example 1 except that the compounding ratio was set as shown in the following Table 1.

[0108] The average particle diameter of the liquid seasoning (W / O / W type emulsified particles) of Example 2 immediately after preparation was 9 μm, and the W / O / W type emulsion contained a particle size of 10 μm or more. Among the O / W type emulsified particles, among the W / O type emulsified particles contained in the W / O / W type emulsified particles, there were three particles having a particle diameter exceeding 3 μm.

Embodiment 3

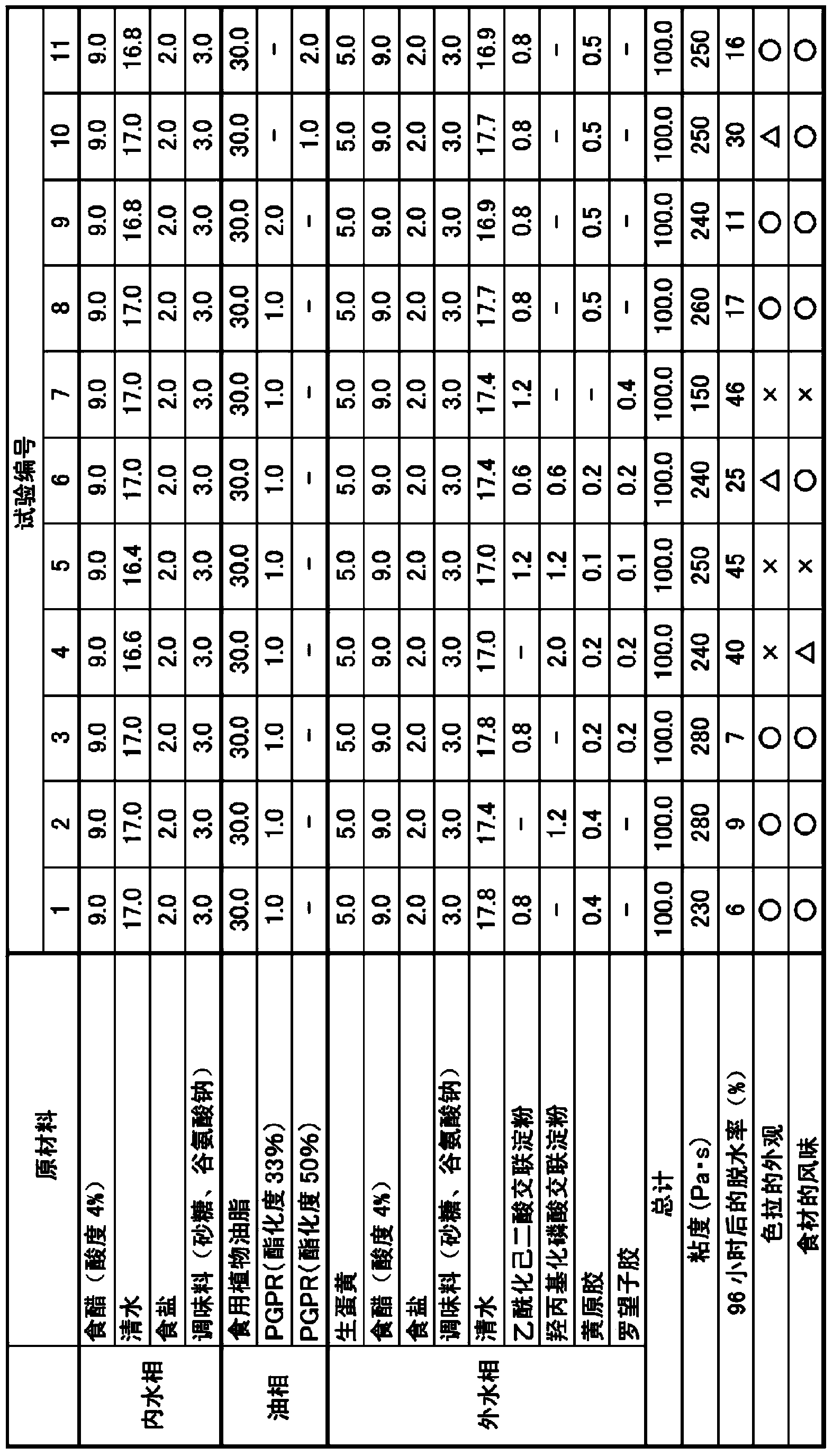

[0114] Emulsified seasonings of test numbers 1 to 11 were prepared in the same manner as in Example 1 except that the compounding ratio of starch and gum and the emulsifier used were shown in Table 2 below. The liquid seasonings (W / O / W type emulsified particles) of test numbers 1 to 11 immediately after preparation had an average particle size of 5 to 15 μm, and the particle size contained in the W / O / W type emulsion was 10 μm Among the above W / O / W type emulsified particles, among the W / O type emulsified particles contained in the W / O / W type emulsified particles, the number of particles having a particle diameter exceeding 3 μm is 5 or less.

[0115] Moreover, the dehydration rate of the emulsified seasoning of test numbers 1-11 was measured by the method similar to Example 1. The results are shown in Table 2.

[0116] [Table 2]

[0117]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com