Rare earth permanent magnetic material and preparation method thereof

A rare earth permanent magnet and raw material technology, which is applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problem that permanent magnet materials cannot obtain high coercive force at the same time, low usage of dysprosium and/or terbium, dysprosium and/or or high terbium usage to achieve high coercive force, low temperature coefficient and high working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

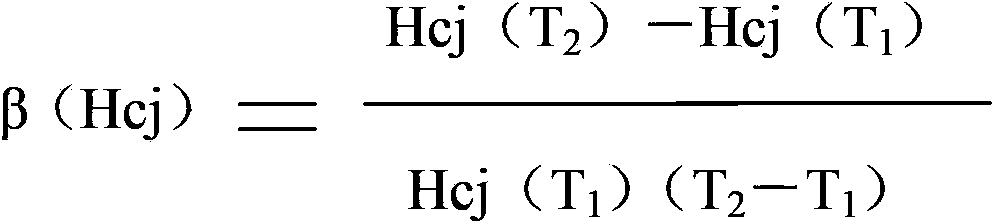

[0019] The invention provides a method for preparing a rare earth permanent magnet material. The method includes sequentially mixing and molding, sintering and tempering the main phase alloy raw material and the auxiliary phase alloy raw material, wherein the composition of the main phase alloy raw material is: R1 x R2 y Fe 100-x-y-z-u co z B u, R1 is selected from Pr and / or Nd; R2 is selected from Dy and / or Tb, wherein, x, y, z, u are mass percentages, and 26%≤x+y≤36%, 0.01%≤y≤6% , 0%≤z≤5%, 0.8%≤u≤1.2%; the composition of the auxiliary phase alloy raw material is: R1 a R2 b Fe 100-a-b-c-n-v co c B n m v , R1 is selected from Pr and / or Nd; R2 is selected from Dy and / or Tb, M is selected from one of Zr, Ga, Cu, Nb, Sn, Mo, Al, V, W, Si, Hf, Ti or Several types, where a, b, c, n, v are mass percentages, and 35%≤a+b≤80%, 5%≤b≤40%, 0%≤c≤40%, 0%≤n≤ 1.2%, 0%≤v≤30%; relative to the total amount of 100 parts by weight of the main phase alloy raw material and the auxiliary ph...

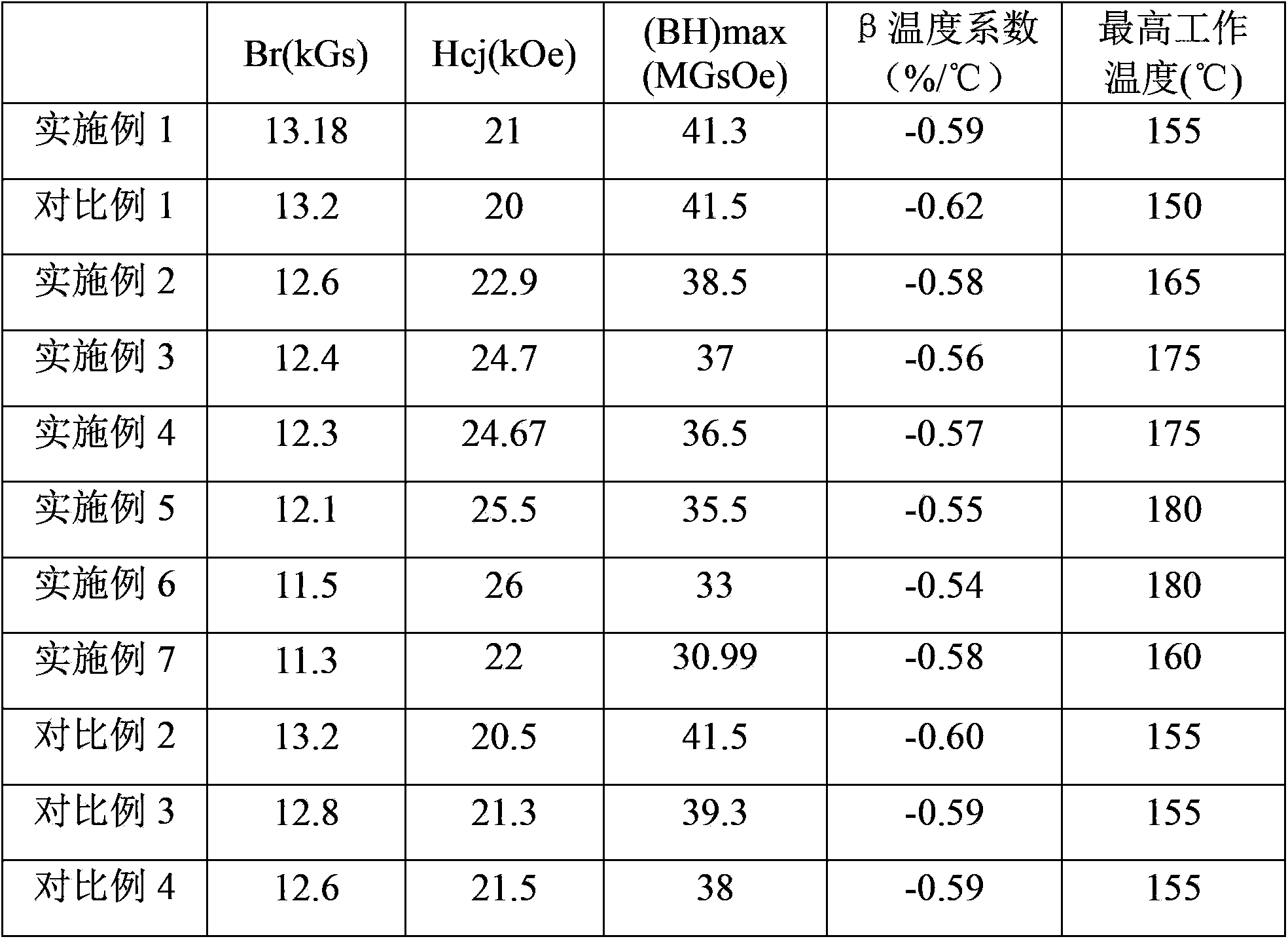

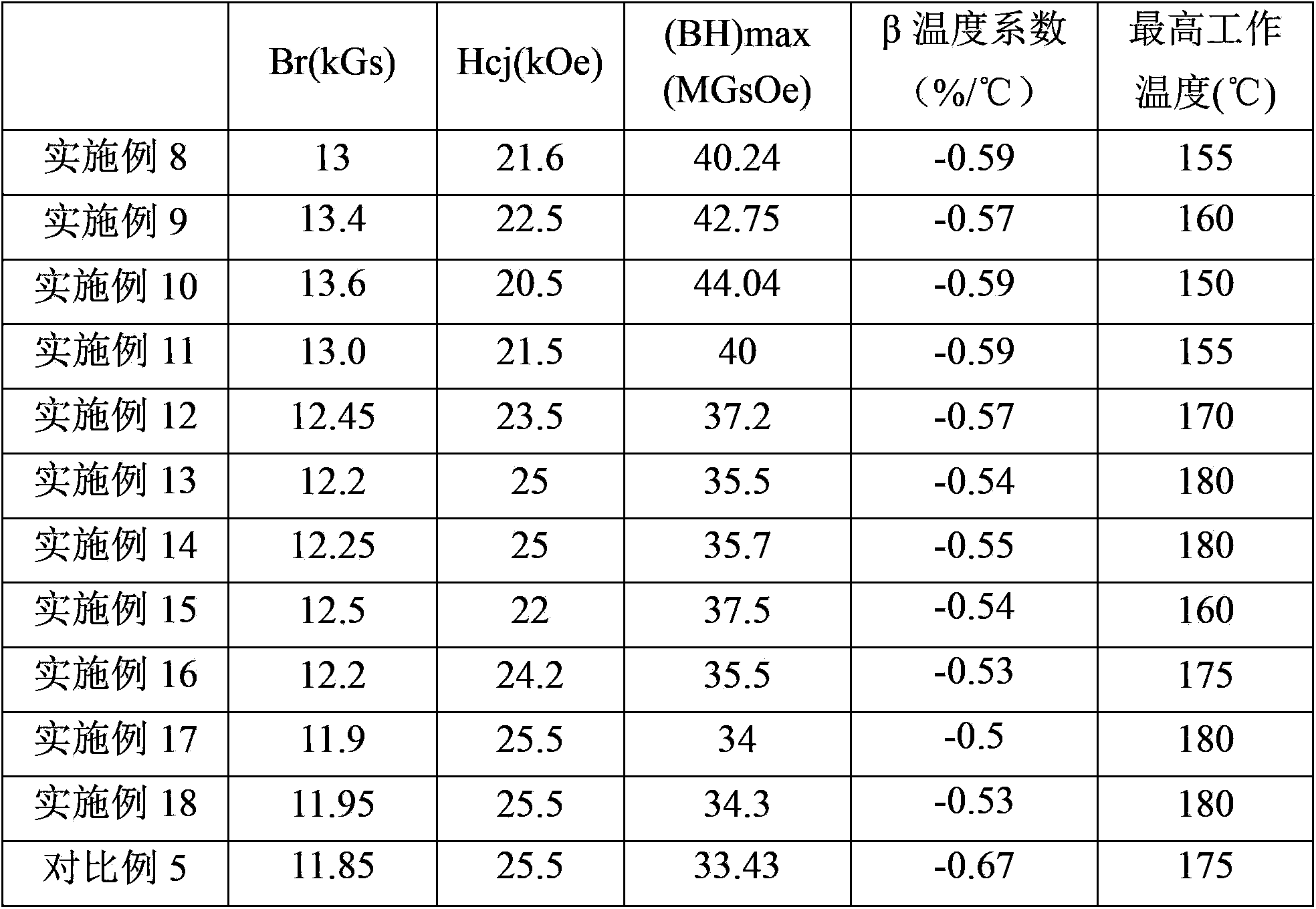

Embodiment 1

[0043] Put the recipe as Pr 5 Nd 23 Dy 3 Tb 0.5 Fe 66.5 co 1 B 1 The raw material is strip-spun at a copper roller surface speed of 1.8m / s to prepare a strip-strip sheet, which is used as the main phase alloy raw material. The main phase alloy raw material was absorbed hydrogen at 15° C. for 2 hours under a hydrogen pressure of 0.15 MPa, and then dehydrogenated at 560° C. for 6 hours, thereby obtaining hydrogen crushed powder of the main phase alloy raw material. Then, mix 100 parts by weight of hydrogen crushed powder of the main phase alloy raw material with 0.05 parts by weight of NdFeB special antioxidant (purchased from Beijing Juncefeng Technology Development Co., Ltd., brand KM-01), and then pass The jet mill grinds to make the main phase alloy raw material fine powder with an average particle diameter of 3.2um, then mix the obtained main phase alloy raw material fine powder with 0.03 parts by weight of gasoline based on the main phase alloy raw material fine powd...

Embodiment 2

[0049] Adopting the preparation method of the rare earth permanent magnet material of embodiment 1, the difference is that relative to the total amount of the main phase precursor and the auxiliary phase precursor of 100 parts by weight, the consumption of the auxiliary phase precursor is 3.5 parts by weight. The magnetic properties of the rare earth permanent magnet material are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com