Dual-fuel nozzle for plasma and gas-assisted atomization burning

A gas-assisted, dual-fuel technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of poor atomization effect of liquid fuel, low combustion efficiency, incomplete fuel combustion, etc., to ensure stability and completeness , Improve the speed of flame propagation, reduce the effect of emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

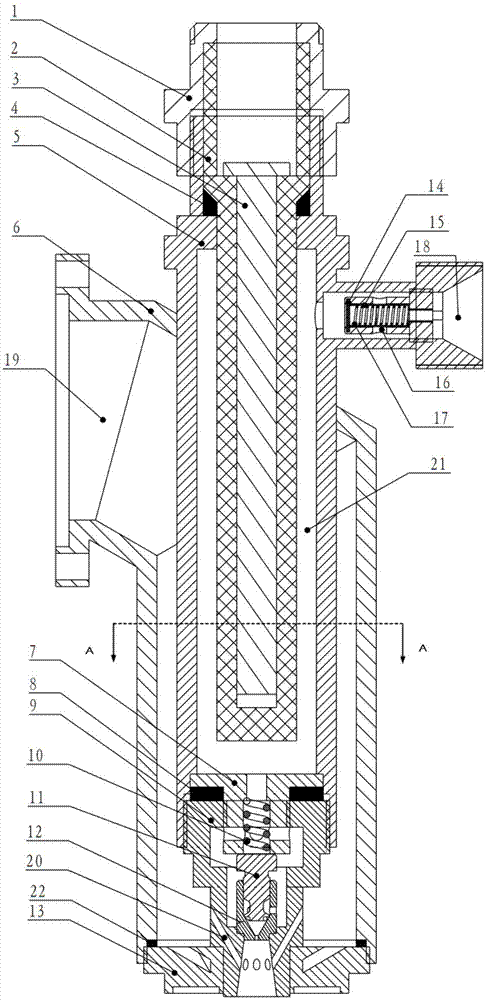

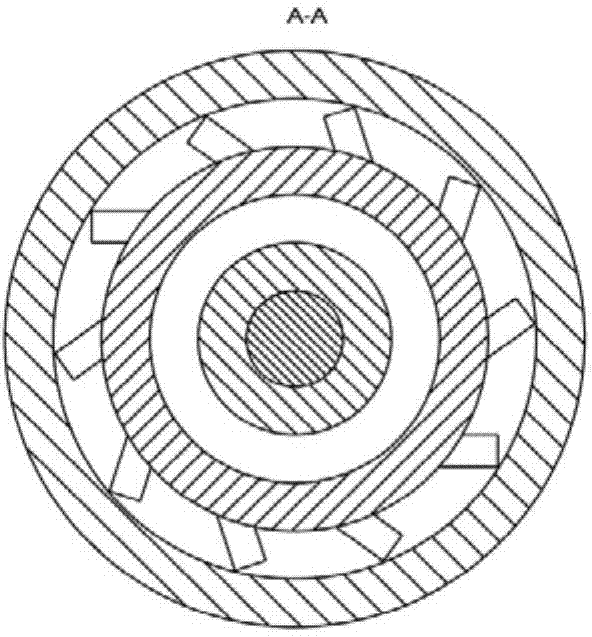

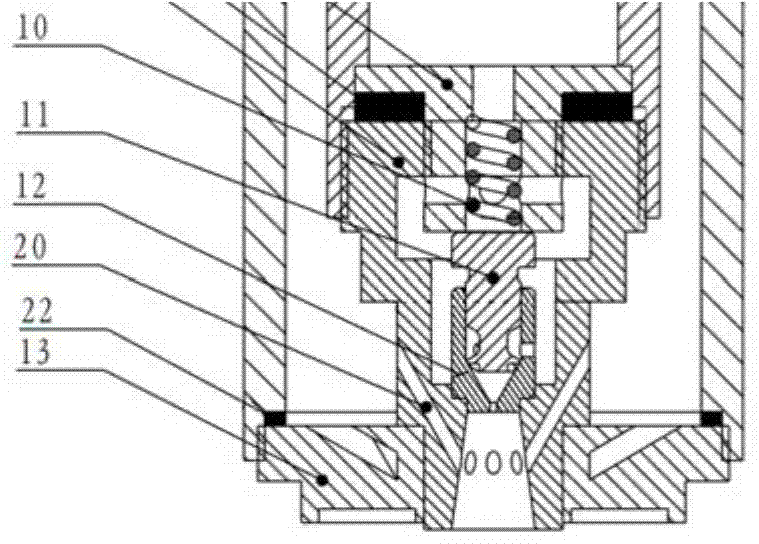

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0018] combine Figure 1~5 , the low-temperature plasma component is connected to the dual-fuel nozzle of plasma and gas-assisted atomization combustion through the external thread of the power connection nut 1 to provide the high voltage required for dielectric barrier discharge, wherein the inner electrode 3 is connected to the high-voltage end, and the outer electrode 5 is connected to zero. The liquid fuel enters the fuel filter assembly composed of the oil baffle plate 14, the oil strainer 15, the oil filter housing 16 and the support spring 17 through welding with the liquid fuel inlet joint 18 on the outer electrode 5, and after filtering Radial into the annular discharge gap 21, the liquid fuel is partially cracked under high voltage to form plasma active micelles, which are contained in the liquid fuel and flow into the swirler bracket 7, sealing gasket 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com