Movable mixed-burning steam generating device

A steam generating device, mobile technology, applied in the direction of steam generating device, steam generation, steam boiler, etc., can solve the problems of immobile, large flow field resistance, high flow loss, etc., achieve uniform and stable rotation strength, improve combustion efficiency, The effect of shortening the flame length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

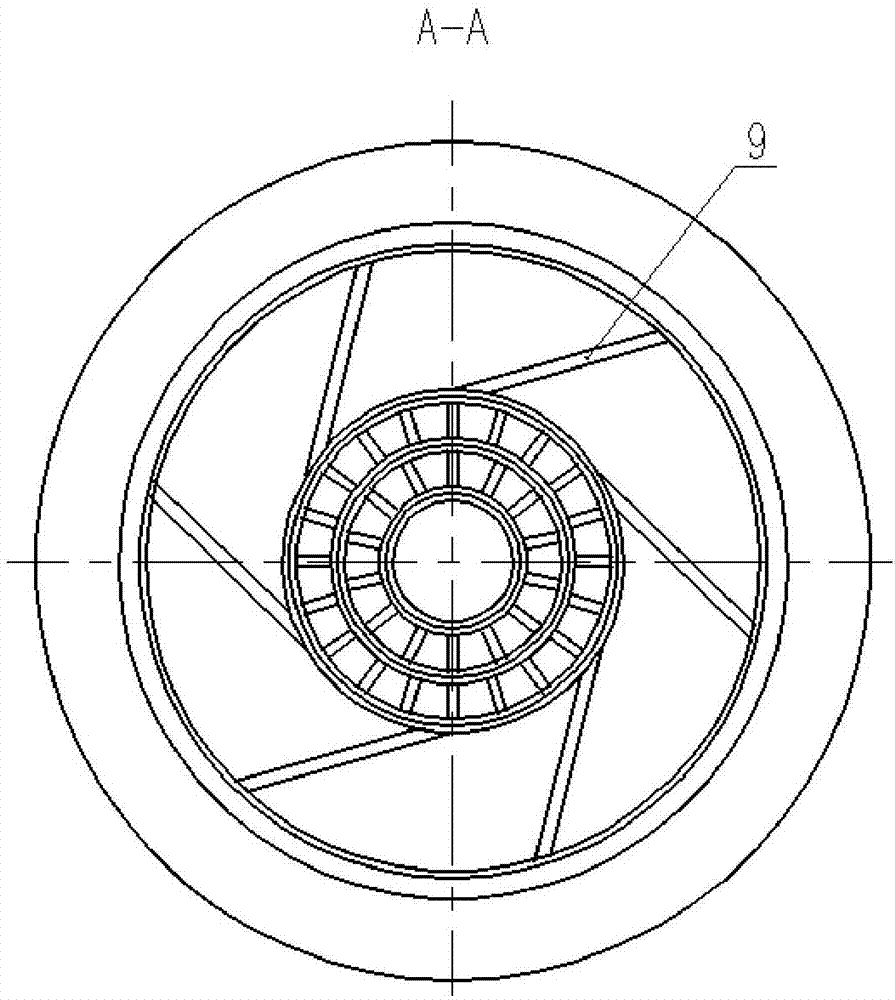

[0040] The mobile co-combustion steam generating device of this embodiment has a structure as attached Figures 1 to 6 As shown, it includes a cylindrical barrel 10 as a device housing, a cover plate 7 fixedly arranged at the inlet end of the barrel, and a flame tube combustion chamber 1 in the front part of the barrel, and a flame tube combustion chamber in the middle along the direction of gas flow. The water film cooling system 2, the rear gas atomization device 3 and the airflow operation monitoring system 4 arranged on the cylinder, the fuel connection 5 and 2 pressure air connection 6 are arranged on the cover plate, and the fuel connection is arranged on the cover plate In the center, the pressure air connection pipes are evenly distributed around the fuel connection pipes. The outlet of the fuel connection pipes is connected to the nozzle 8 located in the head inlet of the flame tube combustion chamber. The pressure air connection pipe outlet is located in front of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com