Continuous composite plating sand overlying tank for diamond cutting line

A diamond cutting wire and diamond micropowder technology, applied in electrolytic coatings, coatings, electrolytic processes, etc., can solve the problems of long coating quality controllability and low electroplating efficiency, and achieve high coating quality controllability and high electroplating efficiency. , good heat resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

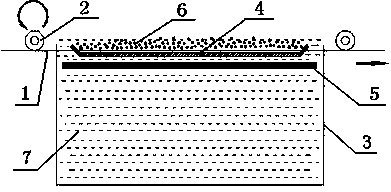

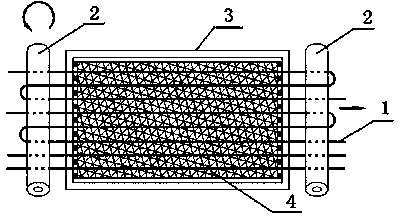

[0021] Embodiment one: see figure 1 with figure 2 As shown, a diamond cutting line continuous composite plating sand tank, including electroplating tank body 3, cathode roller 2, anode frame 5, sand tank 4 and wire wheel, the anode frame 5 is a tin-lead alloy mesh plate frame, the described sand-loading tank 4 is a reticulated flat tank, and baffles are arranged around the described reticulated flat tank, and the baffles at both ends of the reticulated flat tank are set in an inclined trapezoid and are attached with cotton balls, sponges or wool The brush material lightly rubs the steel wire, the nylon mesh with fine aperture is bonded on the described sand tank 4, the cathode roller 2 is connected with the negative pole of the power supply, the anode frame 5 is connected with the positive pole of the power supply, and the cathode roller 2 is connected with the positive pole of the power supply. Located on the outside of the electroplating tank body 3, the electroplating tan...

Embodiment 2

[0022] Embodiment two: with embodiment one, difference is: select the steel wire that diameter is 0.18mm for use, select the diamond micropowder that average particle diameter is 30 μ m for use, cut steel wire 1 winding electroplating tank body 3 two ends cathode roller 2 five circles, cathode roller 2 top The cutting steel wire 1 exposes the diamond micropowder 6 and is immersed in the plating solution 7, finally obtaining a diamond cutting wire with a diameter of 0.25mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com