Plating apparatus and method of manufacturing printed circuit board

A technology for electroplating devices and substrates, which is applied in the manufacture of printed circuits, printed circuits, electrodes, etc., and can solve problems such as the current reduction of anode electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

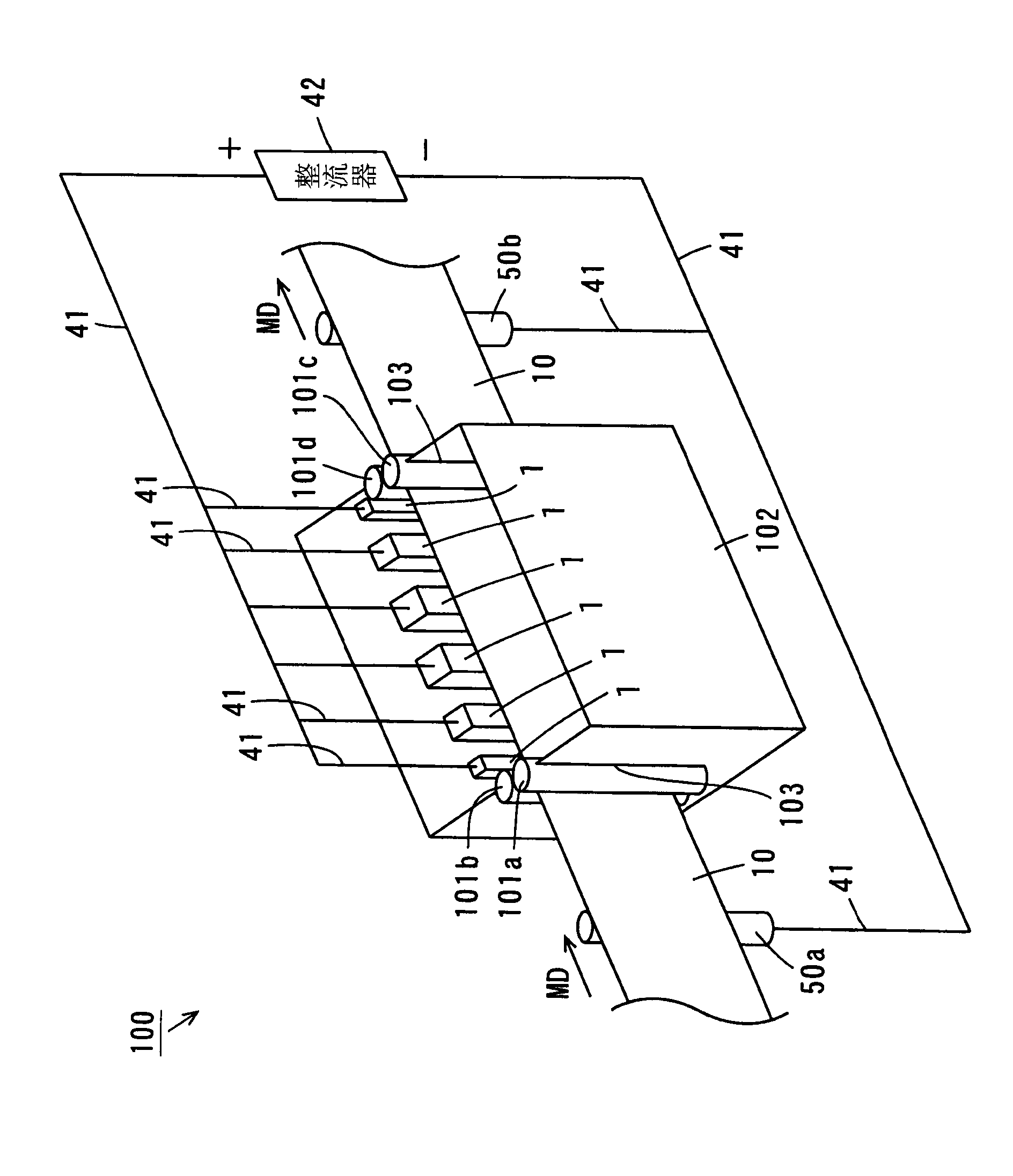

[0062] Regarding the electroplating apparatus 100 of the second embodiment of the present invention, differences from the electroplating apparatus 100 of the above-mentioned first embodiment will be described.

[0063] Figure 4 It is a figure which shows the structure of the some anode electrode 2 of the electroplating apparatus 100 of 2nd Embodiment. Such as Figure 4 As shown, the plating apparatus 100 of the second embodiment has three or more (six in this example) anode electrodes 2 instead of three or more anode electrodes 1 . Each anode electrode 2 has a structure in which a plurality of spherical anode balls 112 made of, for example, copper are accommodated in a mesh-shaped case 110 made of, for example, titanium. Each anode electrode 2 is placed in the plating tank 102 in a state of being accommodated in an acid-resistant anode cover 113 .

[0064] Hereinafter, among the plurality of anode electrodes 2, the two anode electrodes 2 disposed at both ends are respectiv...

Embodiment 2 and Embodiment 3

[0082] In Example 2 and Example 3, the plating apparatus 100 of the above-mentioned second embodiment was used. In embodiment 2, adopt the anode ball 112 that diameter is 27mm, make the quantity of the anode ball 112 of each two ends anode 2 be 25, make the quantity of the anode ball 112 of each middle anode 2 be 45, make each central anode The number of anode balls 112 is 80. In embodiment 3, adopt the anode ball 112 that diameter is 27mm, make the quantity of the anode ball 112 of each two-end anode 2 be 25, make the anode of the intermediate anode 2 on the upstream side on the transport direction of the elongated substrate 10 The number of balls 112 is 45, the number of anode balls 112 of the intermediate anode 2 on the downstream side in the transport direction of the elongated substrate 10 is 50, and the number of anode balls 112 of each central anode 2 is 80.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com