Method for preparing AZO film

A film and equipment technology, applied in the field of AZO film preparation, can solve the problems of high production cost, difficult to popularize and use in a wide range, and achieve the effect of reducing development and production costs and improving optical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

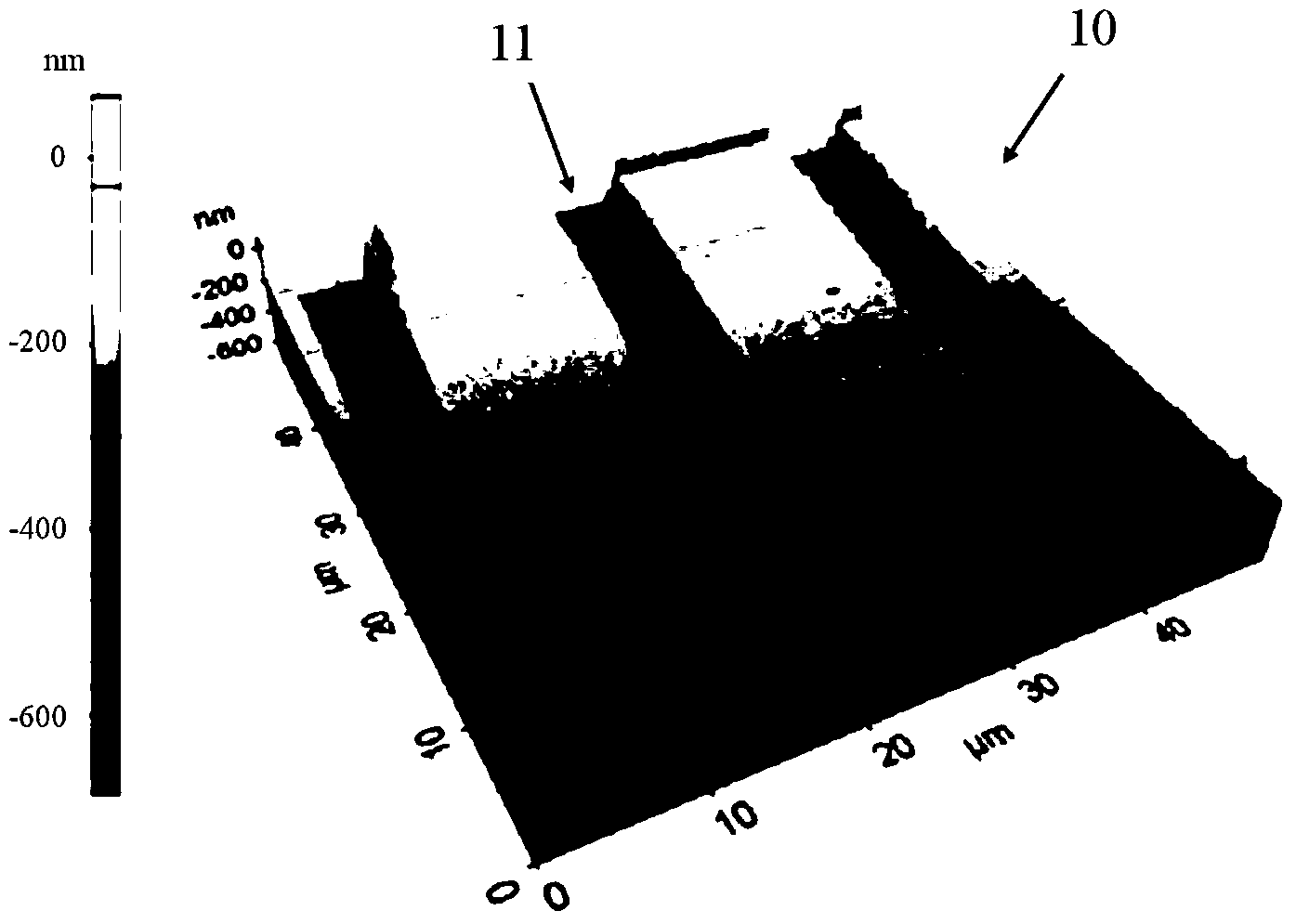

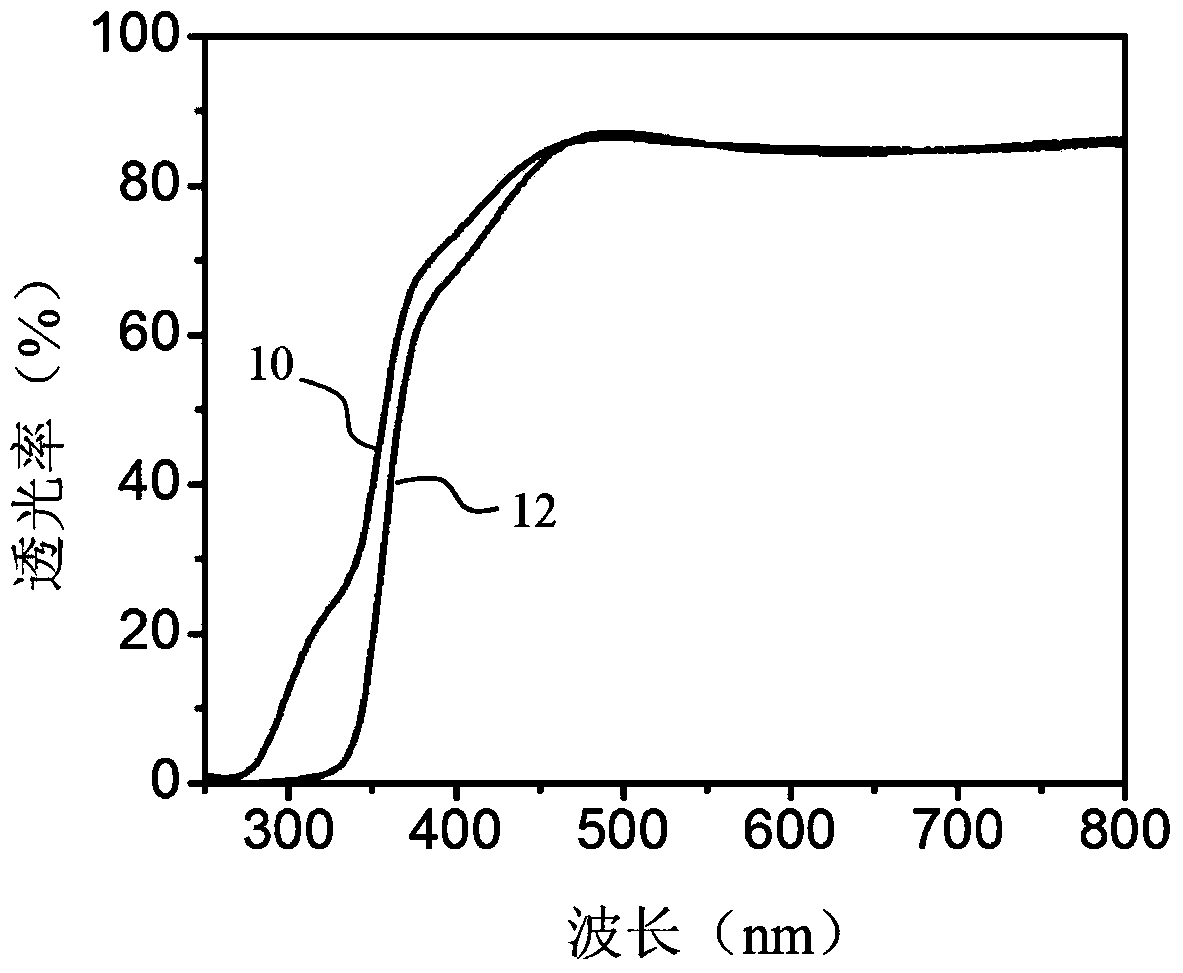

[0017] The preparation method of AZO thin film in the present embodiment is as follows:

[0018] Step 1, magnetron sputtering: In the FJL-560 magnetron sputtering system, the vacuum degree of the vacuum chamber is controlled at 5×10 -4 Above Pa, the quartz substrate after ultrasonic cleaning is fixed on the substrate fixture, and doped with 2wt.% Al 2 o 3 The ZnO ceramic target is used as the cathode sputtering target, and the movable baffle is placed between the substrate fixture and the cathode sputtering target. The working gas used for bombarding the cathode sputtering target is argon with a purity of 99.99% and a pressure of 10 -2 ~10 -1 Pa.

[0019] At 350°C, turn on the DC power supply for ignition, make the argon gas bombard the cathode sputtering target, perform pre-sputtering for 10 minutes, and clean the surface of the target.

[0020] Set the rotation rate of the substrate fixture to 4r / min, turn on the rotation of the substrate fixture, remove the movable baff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com