3D-printing-based machining method of three-dimensional micro-fluidic chip and printing device

A microfluidic chip and 3D printing technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve problems such as easy collapse and lack of support, and achieve high production efficiency, low processing cost, Conducive to the effect of industrial batch manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) First, prepare a mixture of polydimethylsiloxane (PDMS) and a curing agent (the curing agent is a curing agent matched with polydimethylsiloxane in the prior art) with a mass ratio of 10:1, Used as a chip material, a layer of the above mixture is pre-cast on the molding substrate, and the bottom surface of the three-dimensional microfluidic chip is obtained after it is cured;

[0043] 2) Spray solvent-soluble microchannel solid materials layer by layer on the bottom surface of the chip to prepare a three-dimensional microchannel solid structure, including:

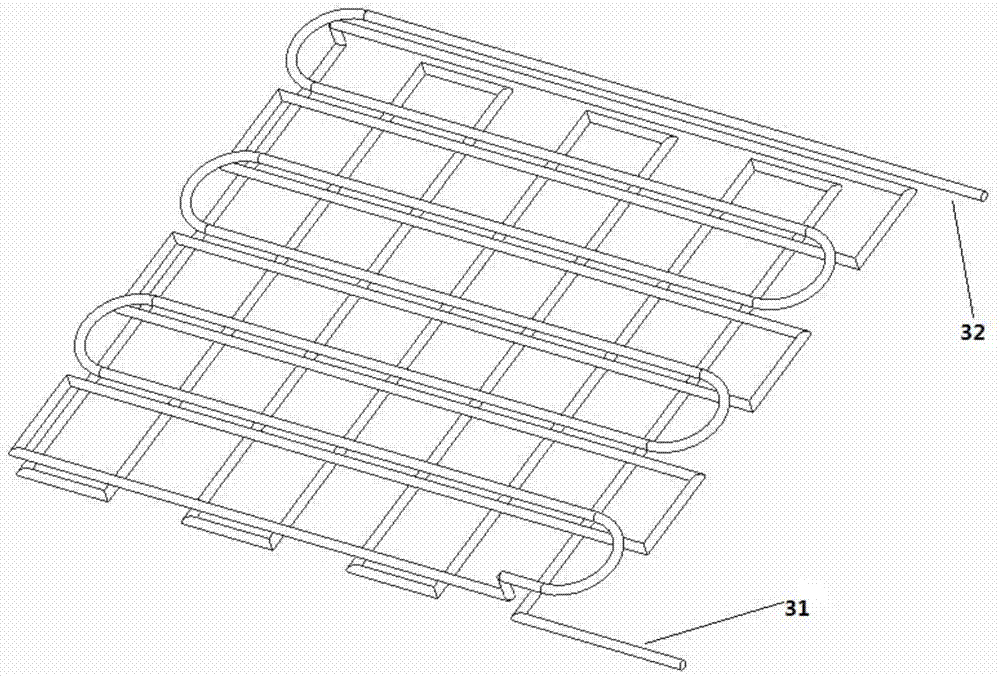

[0044] a) Use CAD software (CorelDraw) to design and draw a three-dimensional microfluidic diagram, the three-dimensional microfluidic diagram is as follows image 3 As shown, the flow channel inlet 31 and the flow channel outlet 32 have been pre-designed, located on the same side of the chip, and adopt a vertical liquid inlet method;

[0045] b) Use commercial CAD software such as CorelDraw for preprocessing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com