Method for preparing copper selenide lithium ion battery electrode material

A technology for lithium ion batteries and electrode materials, which is applied in the field of preparation of electrode materials for copper selenide lithium ion batteries, can solve the problems of low output, unfavorable expansion of production, expensive raw materials, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment one: the preparation method of a kind of copper selenide lithium ion battery electrode material of this embodiment, realizes according to the following steps:

[0022] 1. Add 0.08-0.10g of Na 2 SeO 3 , 0.16~0.20g of Cu(CH 3 COO) 2 Dissolve 0.15-0.25g of NaOH in a mixed solvent of 9-11mL ethylene glycol and 19-21mL deionized water, then place it on a magnetic stirrer and stir for 30-60min at a stirring speed of 4000-8000r / min to obtain a mixture A;

[0023] 2. Add 1-3mL of hydrazine into mixture A and stir evenly to obtain mixed solution B;

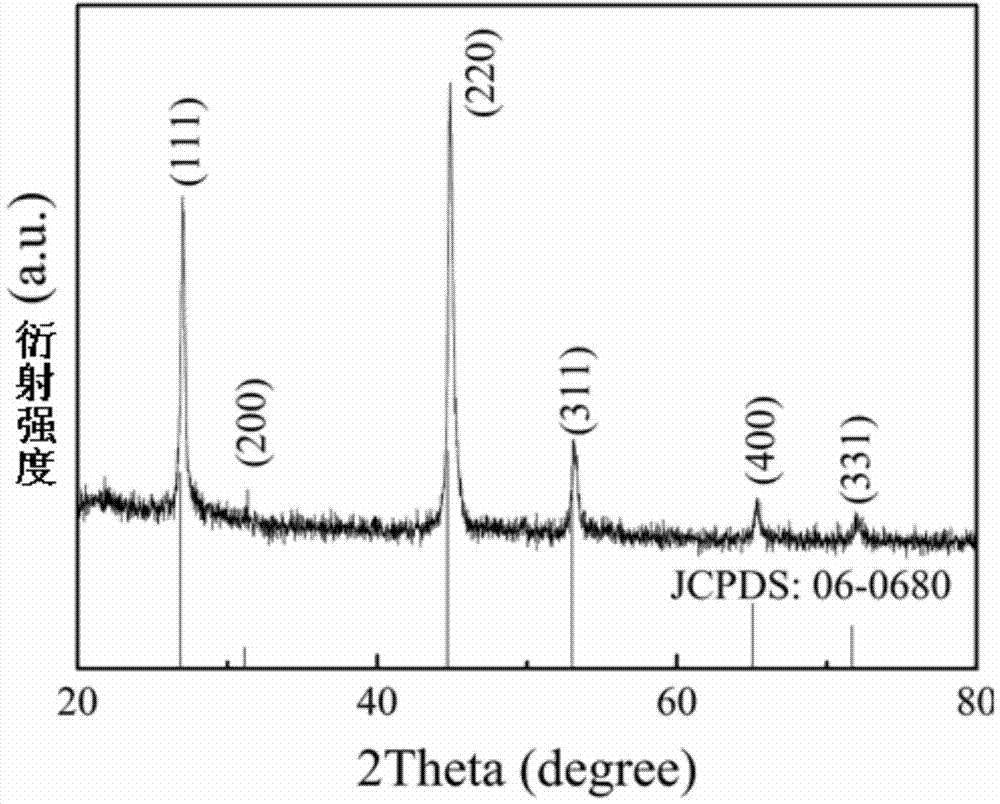

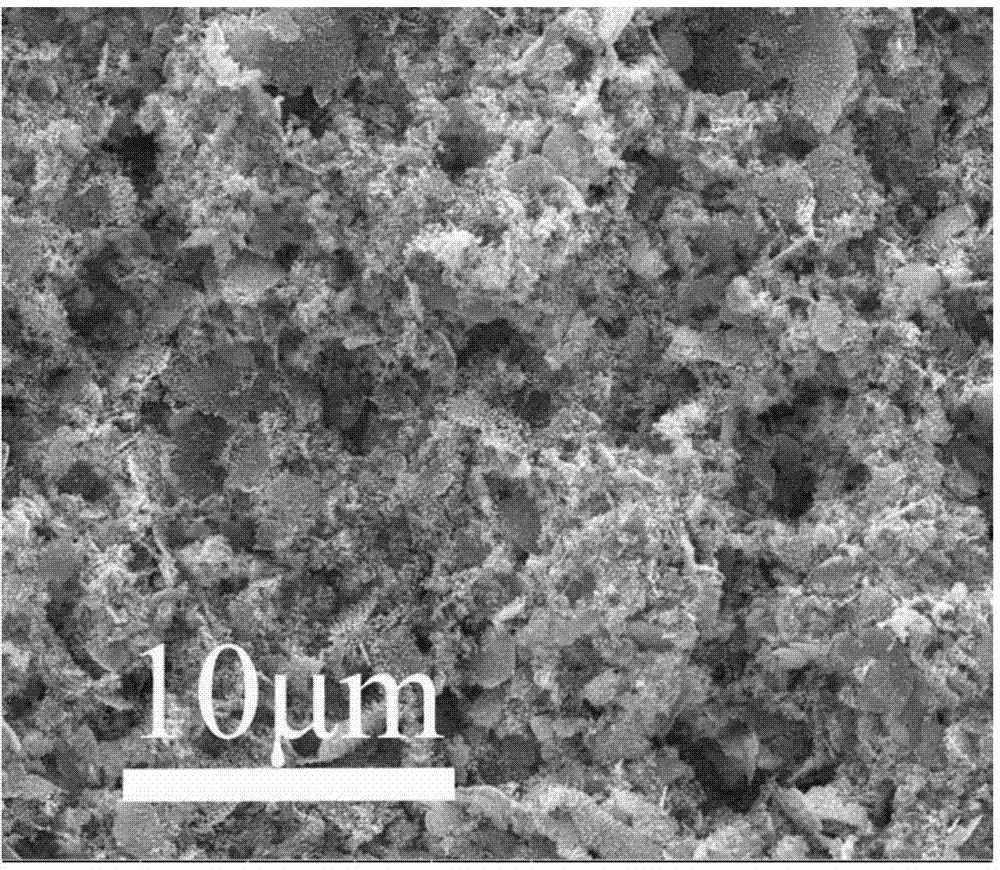

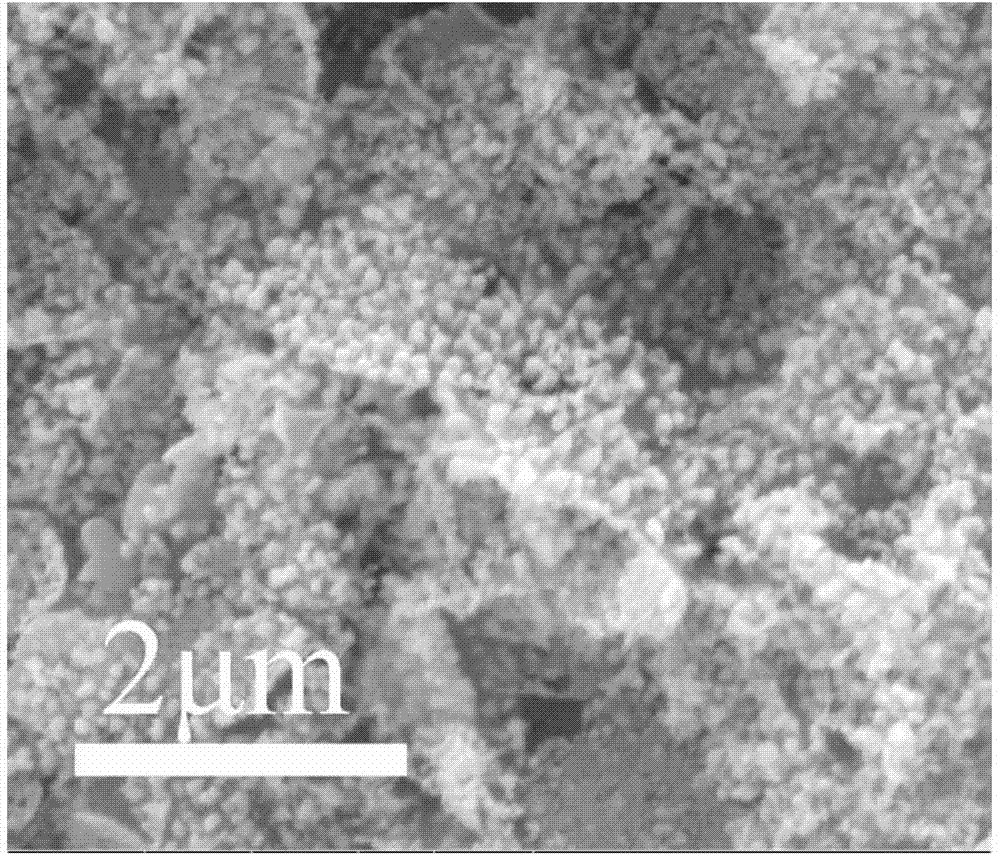

[0024] 3. Add the mixed solution B into a high-pressure reactor lined with polytetrafluoroethylene, seal it, and then heat-treat it at a temperature of 130-200°C for 6-24 hours, and cool it naturally to room temperature to obtain Cu 2-x Se electrode material precursor;

[0025] Fourth, the Cu 2-x Filtrate the precursor of the Se electrode material, then wash it for 3 to 6 times, and then vacuum dry it for ...

specific Embodiment approach 2

[0030] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, 0.09g of Na 2 SeO 3 , 0.18g of Cu(CH 3 COO) 2 and 0.2 g of NaOH were dissolved in a mixed solvent of 10 mL of ethylene glycol and 20 mL of deionized water. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0031] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that in step 1, it is placed on a magnetic stirrer and stirred at a stirring speed of 6000 r / min for 45 min. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com