A kind of nitrogen-doped graphene/copper ferrite nanocomposite material and preparation thereof

A technology of nitrogen-doped graphene and nanocomposite materials, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve low production cost, simple synthesis process, and improved electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

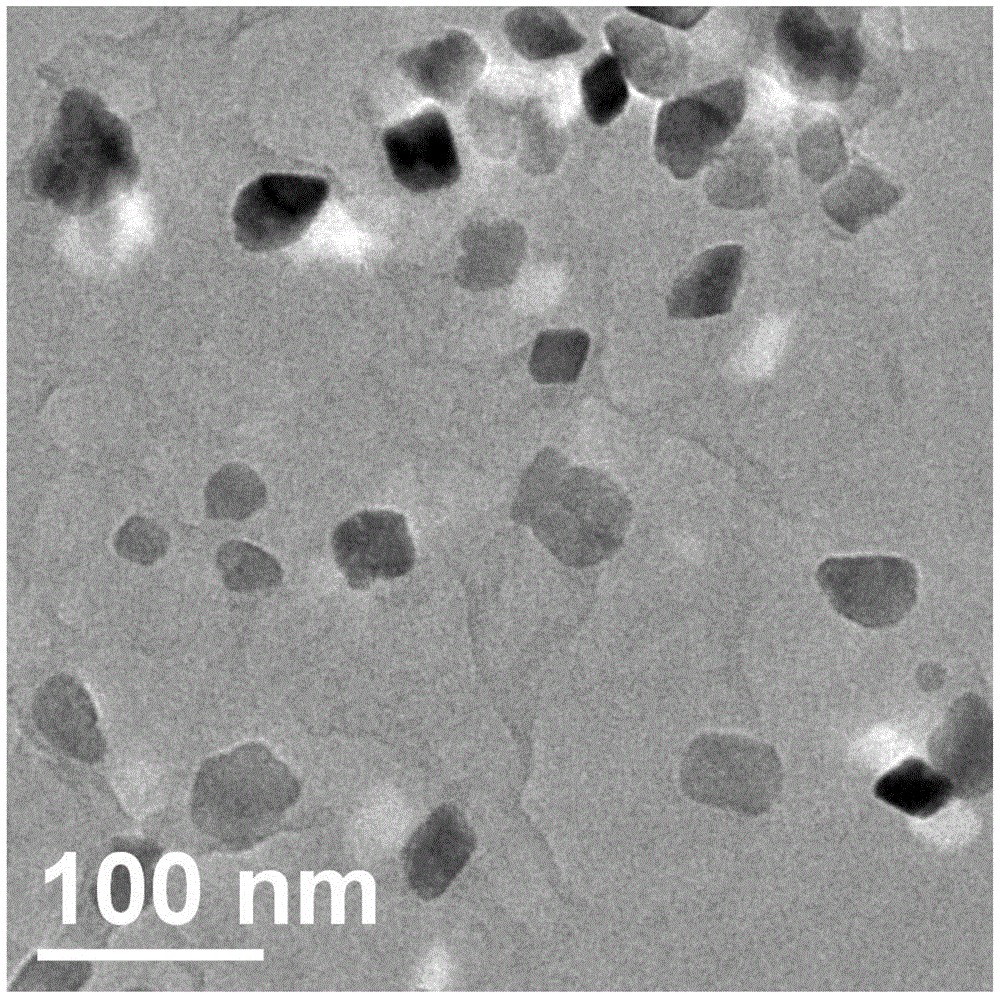

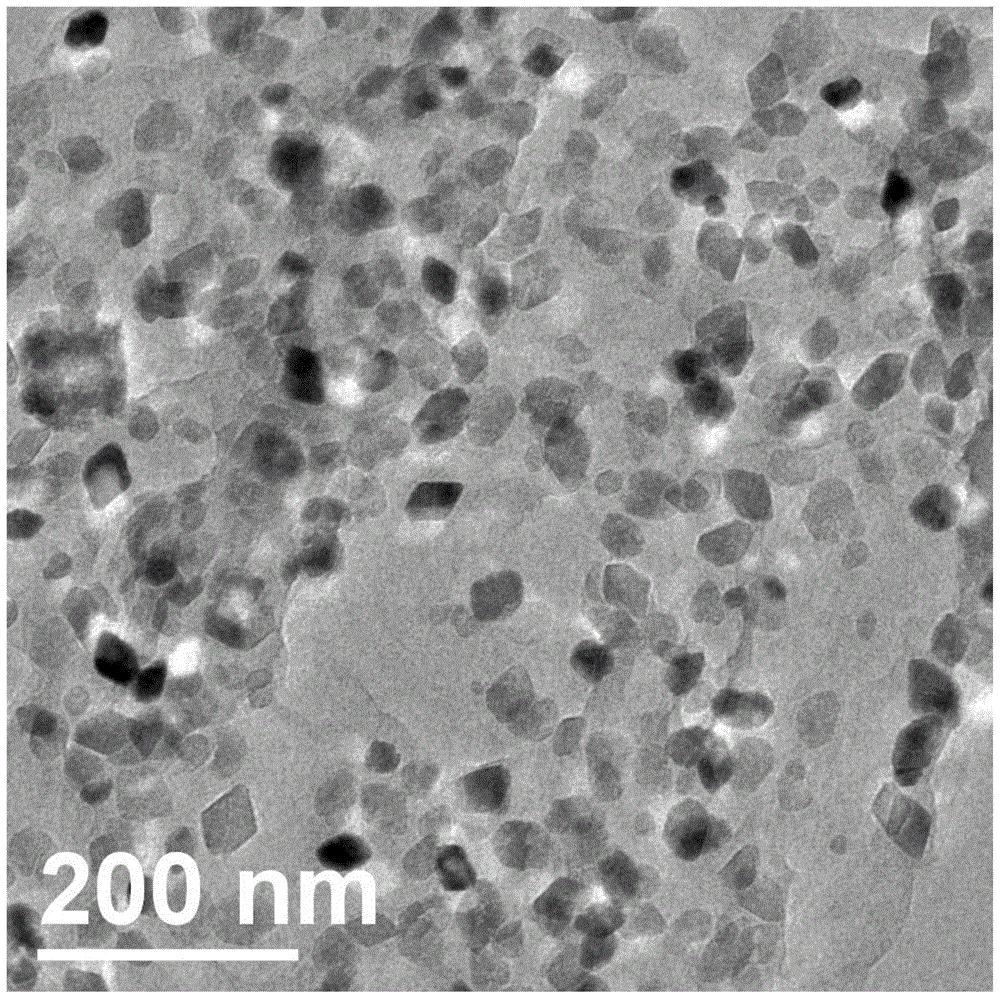

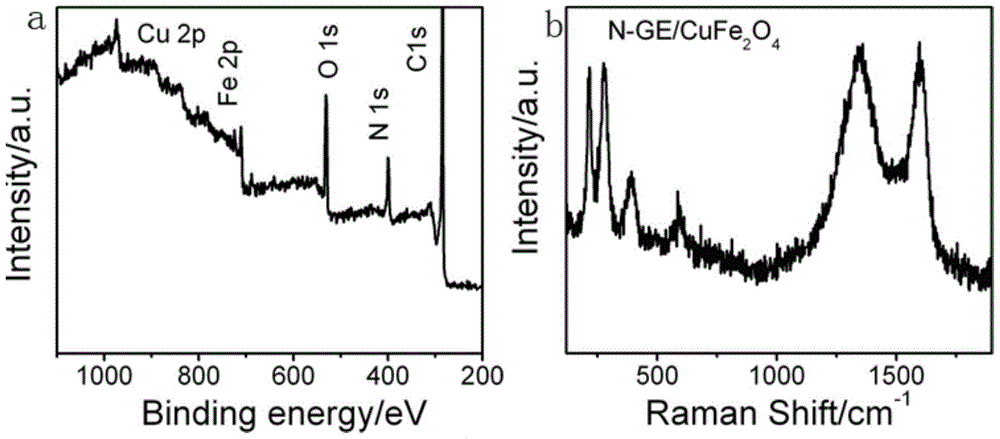

Image

Examples

Embodiment 1

[0023] Implementation Example 1: The preparation method of a nitrogen-doped graphene / copper ferrite nanocomposite material (the mass ratio of graphite oxide to copper ferrite is 1:5) with a nitrogen doping amount of 1%, specifically includes the following steps:

[0024] The first step is to ultrasonicate 100 mg of graphite oxide in 100 mL of mixed solvent (1:1) for 3 hours to obtain a uniformly dispersed graphene oxide solution;

[0025] In the second step, 1.6888g of ferric nitrate and 0.5050g of copper nitrate are added to the above mixed solution, stirred and dispersed for 5min;

[0026] In the third step, 10 g of urea is added to the obtained uniformly dispersed mixed solution, and stirred and dispersed for 30 minutes to make it evenly mixed;

[0027] The fourth step is to transfer the uniformly mixed mixed solution to a hydrothermal kettle for solvothermal reaction, the reaction temperature is 120°C, and the reaction time is 20h;

[0028] Step 5: Centrifuge the product,...

Embodiment 2

[0030] Implementation Example 2: A method for preparing a nitrogen-doped graphene / copper ferrite nanocomposite material (the mass ratio of graphite oxide to copper ferrite is 1:8) with a nitrogen doping amount of 1.5%, specifically comprising the following steps:

[0031] The first step is to ultrasonicate 100 mg of graphite oxide in 100 mL of mixed solvent (1:2) for 3 hours to obtain a uniformly dispersed graphene oxide solution;

[0032] In the second step, 2.7021g of ferric nitrate and 0.8079g of copper nitrate were added to the above mixture, and stirred and dispersed for 20 minutes;

[0033] In the third step, 15g of urea is added to the obtained uniformly dispersed mixed solution, and stirred and dispersed for 40min again to make it evenly mixed;

[0034] The fourth step is to transfer the uniformly mixed mixed solution to a hydrothermal kettle for solvothermal reaction, the reaction temperature is 180°C, and the reaction time is 18h;

[0035] Step 5: Centrifuge the pro...

Embodiment 3

[0037] Implementation Example 3: The preparation method of a nitrogen-doped graphene / copper ferrite nanocomposite material (the mass ratio of graphite oxide to copper ferrite is 1:10) with a nitrogen doping amount of 2%, specifically includes the following steps:

[0038] The first step is to ultrasonicate 100 mg of graphite oxide in 100 mL of mixed solvent (1:4) for 3 hours to obtain a uniformly dispersed graphene oxide solution;

[0039] In the second step, 3.3777g of ferric nitrate and 1.0099g of copper nitrate were added to the above mixture, and stirred and dispersed for 30 minutes;

[0040] In the third step, 20 g of urea is added to the obtained uniformly dispersed mixed solution, and stirred and dispersed for 60 minutes to make it evenly mixed;

[0041] The fourth step is to transfer the uniformly mixed mixed solution to a hydrothermal kettle for solvothermal reaction, the reaction temperature is 200°C, and the reaction time is 12h;

[0042] Step 5: Centrifuge the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com