Inside spin type high-temperature-resisting ultra-quiet drainage pipe and manufacturing method thereof

A manufacturing method and high-temperature-resistant technology, which is applied to hoses, pipes, rigid pipes, etc., can solve the problems of high-temperature-resistant cost and high noise of drainage pipes, and achieve the effects of long service life, reduced friction, and improved impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

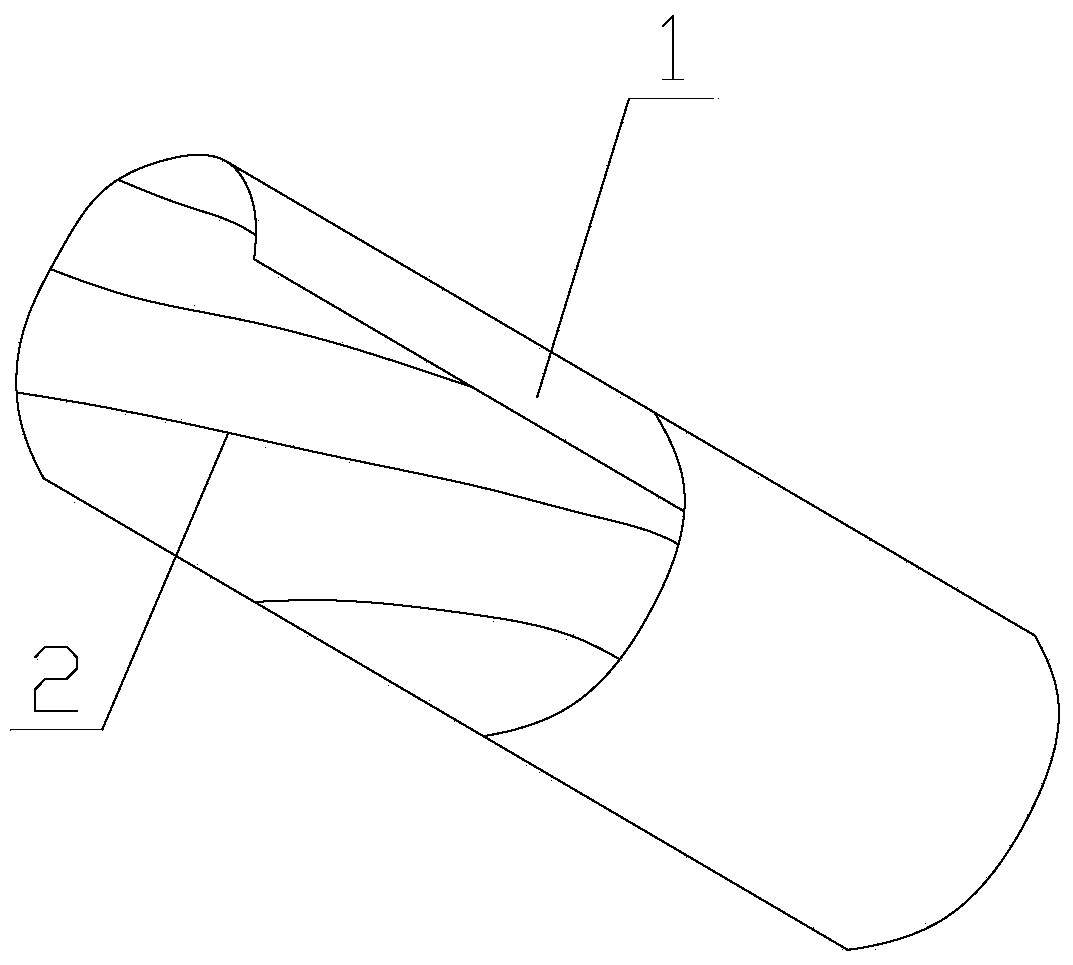

[0041] See attached figure 1 , attached figure 2 And attached image 3 , 35% by weight of block copolymer polypropylene (PP-B), 10% by weight of viscous polymer elastomer, 50% by weight of barium sulfate, 2% by weight of dispersant, 1.5% by weight of even Joint agent, 1.5% by weight lubricant, fully stirred and mixed in a mixer, the mixing temperature is 70 ° C; the uniformly mixed material is extruded and granulated by a co-rotating twin-screw extruder to make silent material granules; Extrude the obtained pellets with a single-screw extruder through a head die with a rotatable threaded mandrel to form a tube blank with a single-layer structure of a noise reduction layer 1. The resulting tube blank is sized and cooled in a vacuum , traction, cutting and turning, and packaged into finished products. In this way, the noise reduction layer 1 single-layer inner spiral high temperature resistant and ultra-quiet is obtained, which is composed of PP-B35%, viscous polymer elastom...

Embodiment 2

[0045] See attached Figure 4 , 25% by weight of block copolymer polypropylene (PP-B), 5% by weight of 1,1,2,2-tetraphenylethylene (TPE), 64.5% by weight of BaSO 4 , the dispersant of 2.5% by weight, the coupling agent of 2% by weight, the stearic acid of 1% by weight, fully stir and mix in the kneader, mixing temperature 90 ℃; The twin-screw extruder is extruded and granulated to make silent material granules; the obtained granules and block copolymerized polypropylene raw materials are respectively passed through a composite co-extrusion head with a rotatable threaded mandrel by two single-screw extruders Die extruded to form a tube blank with a double-layer structure. The tube blank is sequentially composed of a noise reduction layer 1 made of a quiet material and a block copolymerized polypropylene resin layer, which is the first resin layer 3, from the inside to the outside; the obtained tube blank is passed through Vacuum sizing, cooling, pulling, cutting and turning, a...

Embodiment 3

[0049] See attached Figure 5 , 20% by weight of PP-B, 10% by weight of thermoplastic elastomer (POE), 65% by weight of BaSO 4 , the mixture of zinc stearate and polyethylene wax of 2% by weight, the coupling agent of 1% by weight, the white oil of 2% by weight, fully stir and mix in mixer, mixing temperature 110 ℃, will The uniformly mixed material is extruded and granulated by a co-rotating twin-screw extruder to make silent material granules; the above-mentioned granules and block copolymerized polypropylene raw materials are respectively passed through two single-screw extruders with rotatable screw threads. The three-layer composite co-extrusion die of the mandrel is extruded to form a tube blank with a three-layer structure of the inner layer, the noise reduction layer 1 and the outer layer; the obtained tube blank is subjected to vacuum sizing, cooling, traction, cutting and turning, and Packaged into a finished product. Thus, a three-layer inner spiral high temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com