A kind of semiconductor cds/cdsse heterojunction nanowire and preparation method thereof

A nanowire and heterojunction technology, applied in semiconductor devices, chemical instruments and methods, crystal growth, etc., can solve problems such as difficult steam control, inaccurate growth control, and difficulty in high-quality heterojunction nanowires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

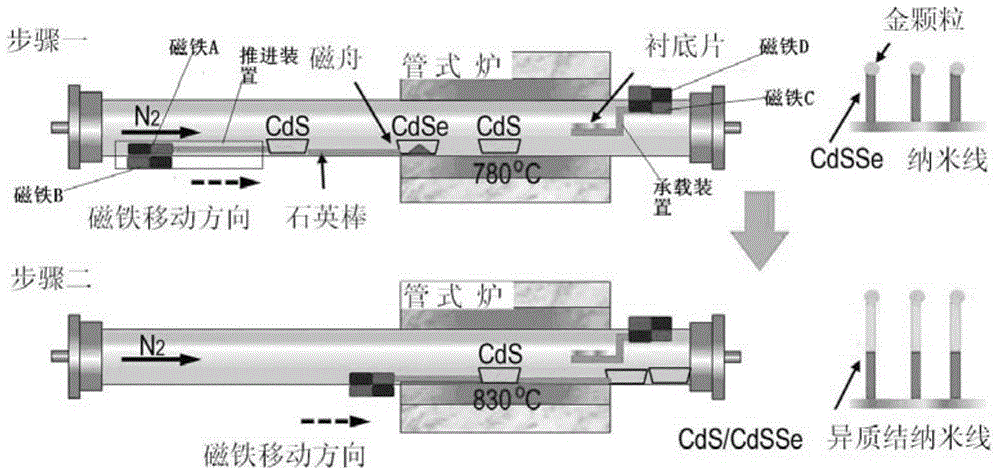

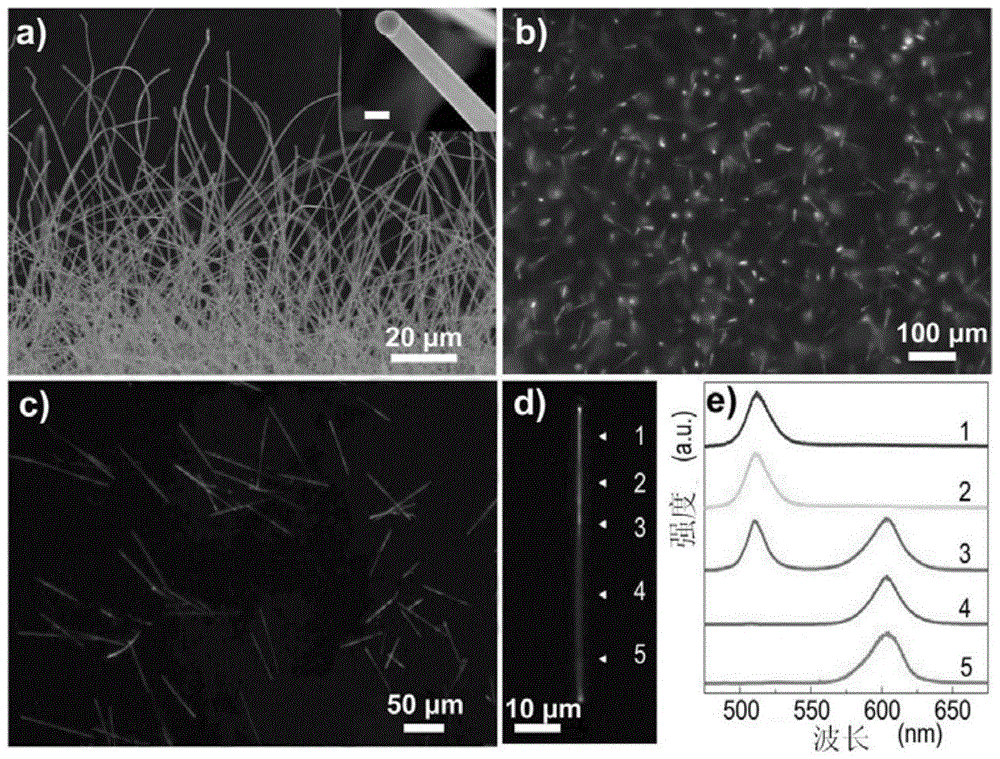

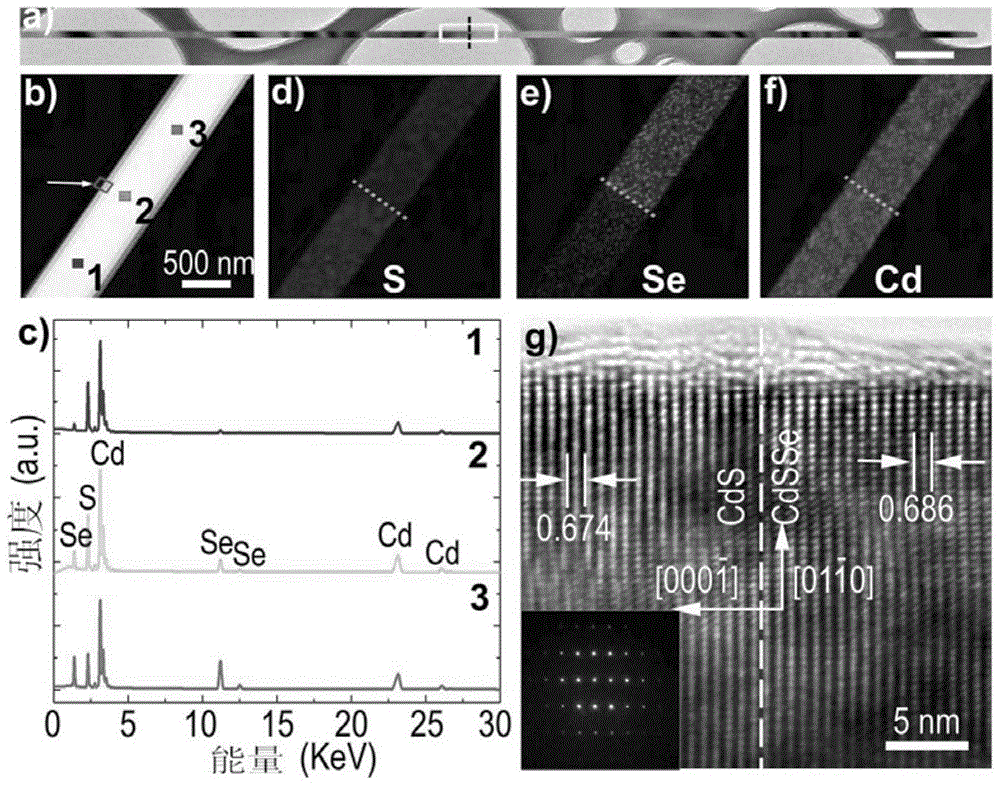

[0097] Example 1 Preparation of CdS / CdSSe heterojunction nanowires

[0098] like figure 1 As shown, a quartz tube with a length of 150 cm and an inner diameter of 45 microns is placed in a horizontal tube furnace, and then No. 1 magnetic boats filled with high-purity cadmium sulfide (Alfa Aesar, greater than 99.99%) are placed in the furnace for heating At the center position, place No. 2 magnetic boat containing cadmium selenide (Alfa Aesar, more than 99.99%) powder in the evaporation area, and place No. 3 magnetic boat containing cadmium sulfide powder outside the upstream heating area before heating, and No. 3 magnetic boat A quartz rod is set between the boat and the No. 2 magnetic boat, and the No. 3 magnetic boat is connected with the propulsion device; the propulsion device is composed of a synchronous motor and a quartz rod fixed on the synchronous motor, which is used to push the No. The purpose of the react source. A silicon wafer with a 10nm thick gold film on the s...

Embodiment 2

[0101] Example 2 Preparation of CdS / CdSSe / CdS heterojunction nanowires

[0102] use as figure 1 As shown in the device, a quartz tube with a length of 150 cm and an inner diameter of 45 microns is placed in a horizontal tube furnace, and then the No. 3 magnetic boat filled with high-purity cadmium sulfide (Alfa Aesar, greater than 99.99%) is placed in the furnace for heating At the center, place No. 1 magnetic boat filled with high-purity cadmium sulfide (Alfa Aesar, greater than 99.99%) between the air inlet and No. 3 magnetic boat, and outside the heating zone of the horizontal tube furnace. No. 1 magnetic boat Quartz rods are set between the No. 3 magnetic boat and the No. 2 magnetic boat; the No. 2 magnetic boat is placed between the air inlet and the No. 1 magnetic boat, and the quartz rod is set between the No. 1 magnetic boat and the No. 2 magnetic boat. The device is connected, and the propulsion device is composed of a synchronous motor and a quartz rod fixed on the ...

Embodiment 3

[0104] use as figure 1 As shown in the device, a quartz tube with a length of 150 cm and an inner diameter of 45 microns is placed in a horizontal tube furnace, and then No. 1 magnetic boats filled with high-purity cadmium sulfide (Alfa Aesar, greater than 99.99%) are placed in the furnace At the center of heating, place No. 2 magnetic boat containing cadmium selenide (Alfa Aesar, greater than 99.99%) powder in the evaporation area, and place No. 3 magnetic boat containing cadmium sulfide powder outside the upstream heating area before heating. No. 3 A quartz rod is set between the magnetic boat and the No. 2 magnetic boat, and the No. 3 magnetic boat is connected with the propulsion device; The purpose of replacing the reactive source. A silicon wafer with a 5nm thick gold film on the surface was placed downstream of the evaporation zone (that is, the deposition zone) to collect samples. Before heating, pass nitrogen gas at a rate of 100SCCM, remove the oxygen in the cavity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com