Preparation and application of carbon nanotube membrane electrode cnt-ti electrode as catalyst carrier

A carbon nanotube film, catalyst carrier technology, applied in electrolytic coatings, electrochemical water/sewage treatment, coatings, etc., can solve the problems of CNTs layer damage, difficult separation operation, unfavorable practical application, etc., and achieve good film forming effect. , the effect of large specific surface area and optimal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

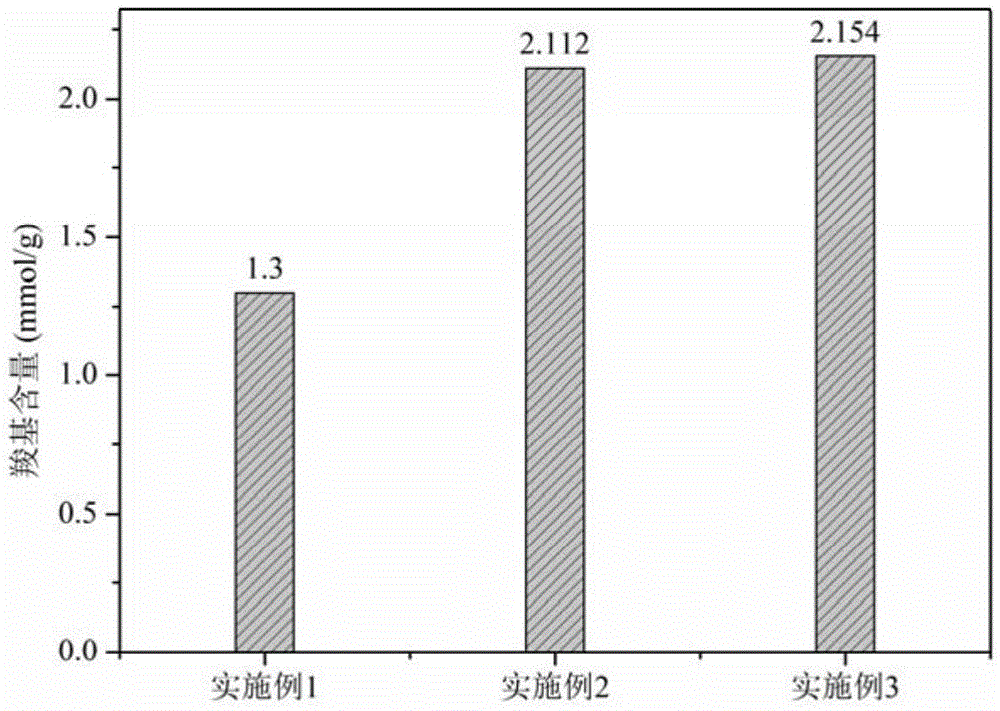

Embodiment 1

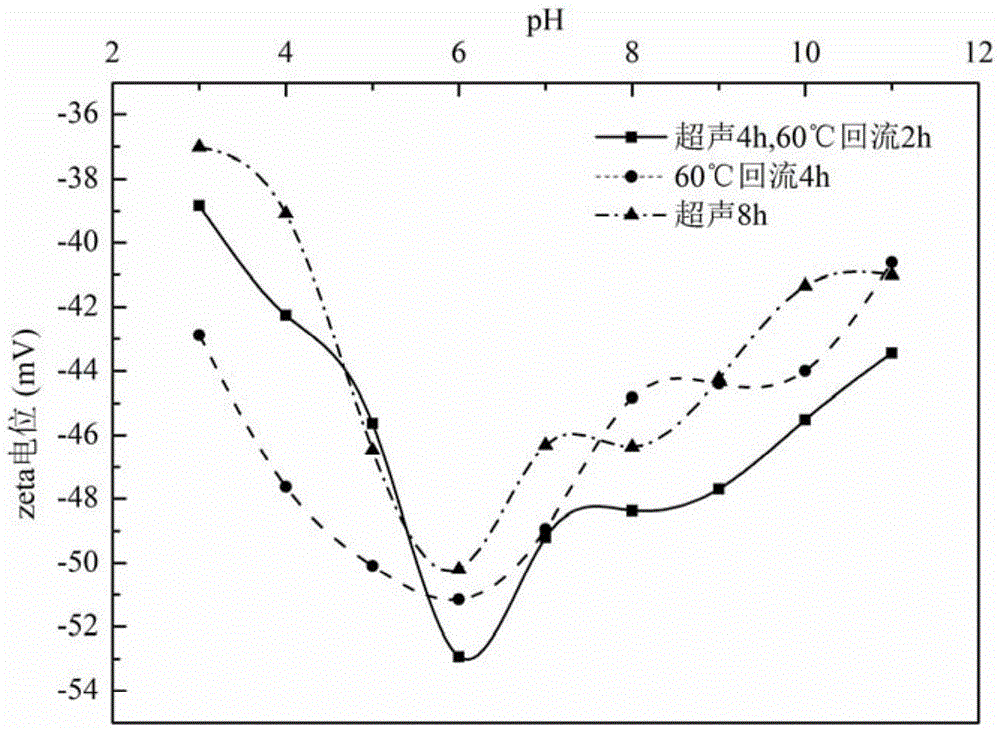

[0029] 1. Weigh 800mg of CNTs, add 25mL of concentrated nitric acid and 75mL of concentrated sulfuric acid After using an ultrasonic cleaner at room temperature for 8 hours, centrifuge to remove most of the acid, filter and wash the CNTs with deionized water until neutral, and dry them for later use;

[0030] 2. Weigh 10 mg of CNTs prepared in step 1, add 20 mL of deionized water, and ultrasonically disperse for 0.5 h to prepare a 0.5 mg / mL CNTs dispersion. Adjust the pH value to 6 with 0.05mol / L NaOH solution, and place it for later use.

[0031] 3. Cut the 150-mesh Ti net into a size of 2cm×2cm, soak it in 40% NaOH solution at 80°C for 2 hours to remove surface oil, wash it with distilled water until it is neutral, then soak it in 15% oxalic acid solution to remove the surface Oxides, kept at 98°C for 2 hours, rinsed with distilled water, and dried with nitrogen for later use;

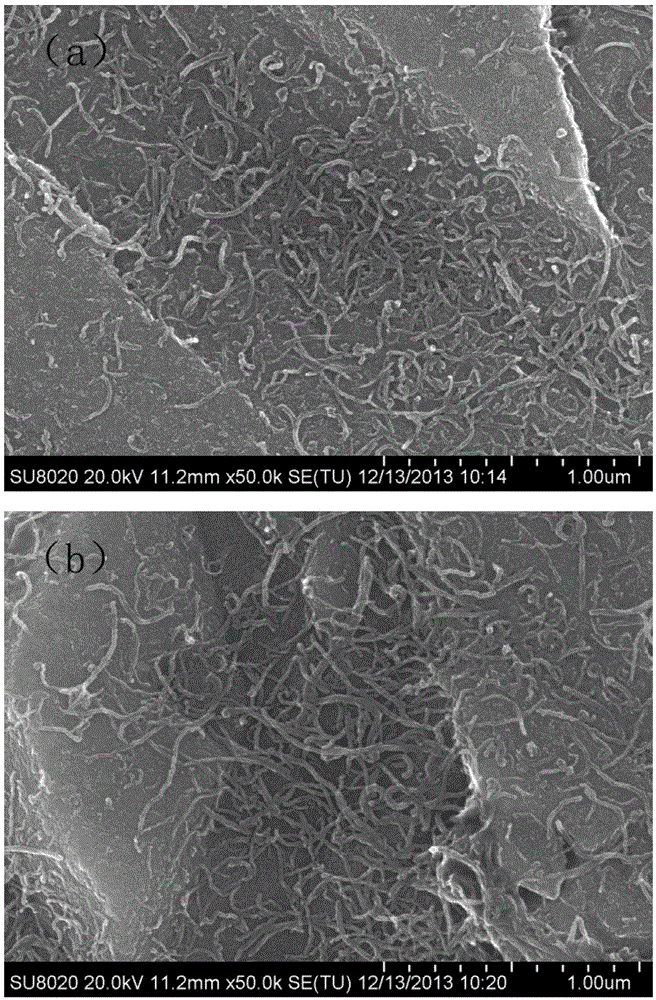

[0032] 4. Use the CNTs dispersion liquid configured in step 2 as the electrophoretic depositio...

Embodiment 2

[0035] 1. Weigh 800mg of CNTs, add 25mL of concentrated nitric acid and 75mL of concentrated sulfuric acid After refluxing at 60°C for 4 hours, centrifuge to remove most of the acid, filter and wash the CNTs with deionized water until neutral, and dry them for later use;

[0036] 2. Weigh 10 mg of CNTs prepared in step 1, add 20 mL of deionized water, and ultrasonically disperse for 0.5 h to prepare a 0.5 mg / mL CNTs dispersion. Adjust the pH value to 6 with 0.05mol / L NaOH solution, and place it for later use.

[0037] 3. Cut the 150-mesh Ti net into a size of 2cm×2cm, soak it in 40% NaOH solution at 80°C for 2 hours to remove surface oil, wash it with distilled water until it is neutral, then soak it in 15% oxalic acid solution to remove the surface Oxides, kept at 98°C for 2 hours, rinsed with distilled water, and dried with nitrogen for later use;

[0038] 4. Use the CNTs dispersion liquid configured in step 2 as the electrophoretic deposition liquid, use the Ti mesh trea...

Embodiment 3

[0041] 1. Weigh 800mg of CNTs, add 25mL of concentrated nitric acid and 75mL of concentrated sulfuric acid After 4 hours of ultrasonic cleaning at room temperature, reflux at 60°C for 2 hours, centrifuge to remove most of the acid, filter and wash the CNTs with deionized water until neutral, and dry them for later use;

[0042] 2. Weigh 10 mg of CNTs prepared in step 1, add 20 mL of deionized water, and ultrasonically disperse for 0.5 h to prepare a 0.5 mg / mL CNTs dispersion. Adjust the pH value to 6 with 0.05mol / L NaOH solution, and place it for later use.

[0043] 3. Cut the 150-mesh Ti net into a size of 2cm×2cm, soak it in 40% NaOH solution at 80°C for 2 hours to remove surface oil, wash it with distilled water until it is neutral, then soak it in 15% oxalic acid solution to remove the surface Oxides, kept at 98°C for 2 hours, rinsed with distilled water, and dried with nitrogen for later use;

[0044] 4. Use the CNTs dispersion liquid configured in step 2 as the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com