Method for making silica film on surface of quartz substrate

A technology of silicon dioxide film and quartz substrate, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of inability to prepare, poor controllability of sputtering method, slow rate of thermal oxidation method, etc. Achieve the effects of avoiding precipitation and improving film production efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

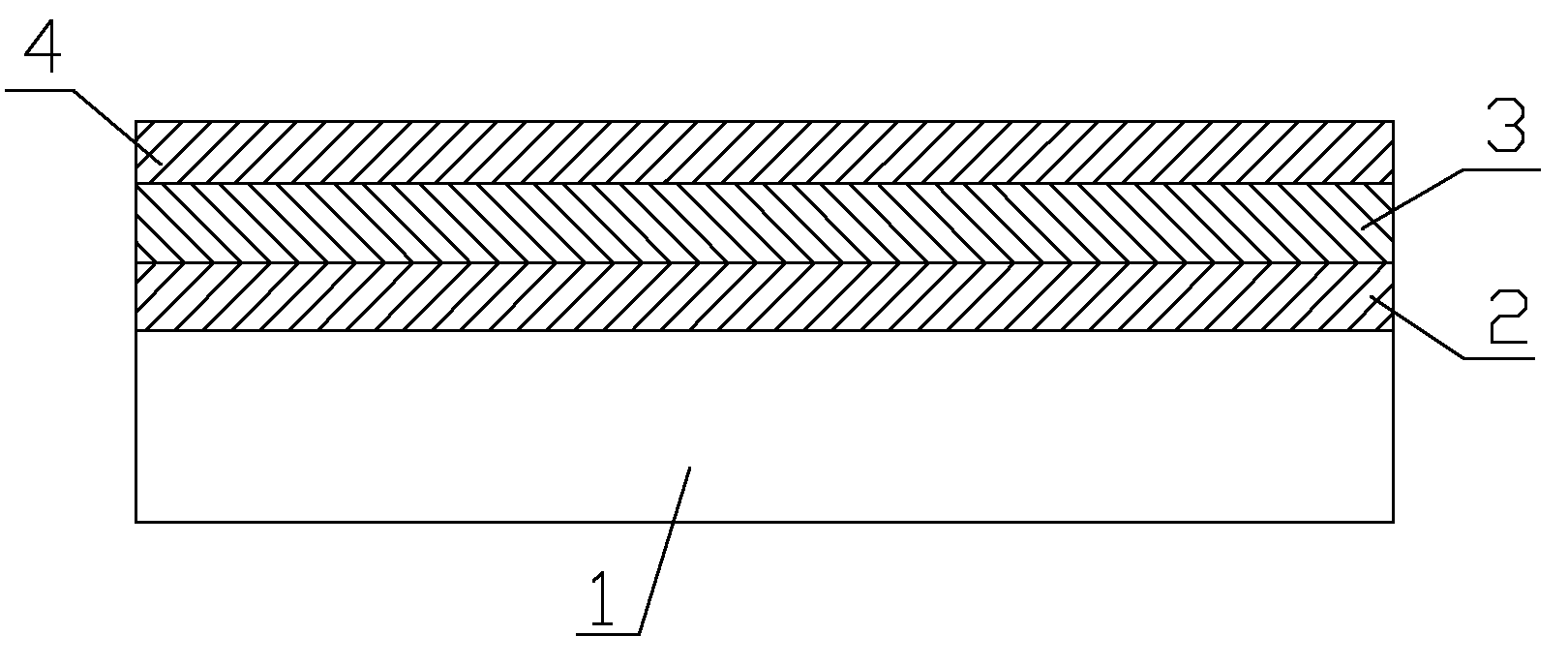

Image

Examples

Embodiment Construction

[0018] The method for preparing silicon dioxide film on the surface of quartz substrate of the present invention comprises the following steps:

[0019] Step 1. Place the quartz substrate on a rotating and temperature-controlled stage, and use a hydrogen-oxygen flame at a high temperature of 2500-3000 ° C to generate a lower cladding on the surface of the quartz substrate through a hydrolysis reaction. SiCl 4 、H 2 , O 2 gas, the ventilation volume is SiCl respectively 4 8-15sccm, H 2 25-35 sccm, O 2 12-20sccm, control stage temperature 450-500℃, growth rate 5-6um / m, lower cladding growth thickness 15-20um;

[0020] Step 2. After the growth of the lower cladding layer is completed, put the sample into the vacuum rapid annealing furnace. The heating rate of the annealing furnace is 40-50°C / s. / s rises to 1380-1430°C, keeps for 4-5 hours, then cools down to 25°C at 40-50°C / s, takes out the sample, washes the surface of the lower cladding with acetone, ethanol, and wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com