Black plum extract, preparation method for same and application of extract to cigarette

A technology of extract and black brin, which is applied in the field of black brin extract and its preparation, can solve problems such as cigarettes that have not yet been applied, and achieve the effects of no irritating aftertaste, improved internal quality, and soft smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

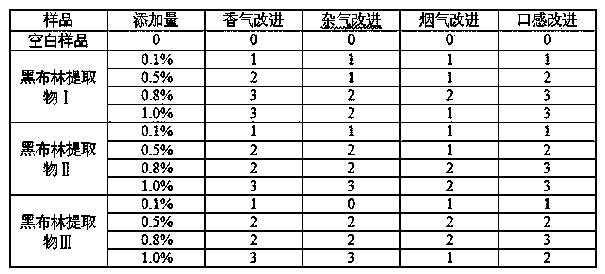

Image

Examples

Embodiment 1

[0021] Take 300 grams of Heibulin, put it into a distillation bottle, add 2400 grams of water, soak for 4 hours, distill at 50°C for 3 hours, after cooling, filter the filtrate with a 200-mesh filter, and concentrate the filtrate to 300 grams to obtain crude Extract. The content of starch and pectin in the crude extract was determined. The starch content was determined by the hydrochloric acid hydrolysis-copper reduction direct titration method, and the pectin content was determined by the carbazole colorimetric method. Add amylase and pectinase respectively according to 0.5% and 1.0% of starch and pectin content in the crude extract (the stated percentage is by weight). The activity units of the two enzymes used are respectively: amylase activity 10,000 u / ml, pectinase activity 40,000 u / ml (both international standard units). Enzymolysis was stirred at 45°C for 24 hours. Then, heat the enzymatic hydrolysis solution to 80° C. and keep the temperature for 15 minutes. After ...

Embodiment 2

[0023] Take 300 grams of Heibulin, put it into a distillation bottle, add 3000 grams of water, soak for 4 hours, distill at 60°C for 4 hours, after cooling, filter the filtrate with a 200-mesh filter, and concentrate the filtrate to 300 grams to obtain crude Extract. The content of starch and pectin in the crude extract was determined. The starch content was determined by the hydrochloric acid hydrolysis-copper reduction direct titration method, and the pectin content was determined by the carbazole colorimetric method. Add amylase and pectinase respectively according to 1.0% and 2.0% of the content of starch and pectin in the crude extract (the stated percentage is by weight), and the activity units of the two enzymes used are: ml, pectinase enzyme activity 50,000 u / ml (both international standard units). Enzymolysis was stirred at 50°C for 48 hours. Then, heat the enzymatic hydrolyzate to 85° C. and keep the temperature for 20 minutes. After cooling, the enzymolyzate is c...

Embodiment 3

[0025] Take 300 grams of Heibulin, put it into a distillation bottle, add 3600 grams of water, soak for 4 hours, distill at 70°C for 5 hours, after cooling, filter the filtrate with a 150-mesh filter, and concentrate the filtrate to 300 grams to obtain crude Extract. The content of starch and pectin in the crude extract was determined. The starch content was determined by the hydrochloric acid hydrolysis-copper reduction direct titration method, and the pectin content was determined by the carbazole colorimetric method. Add amylase and pectinase respectively according to 1.5% and 3.0% of the content of starch and pectin in the crude extract (the stated percentage is by weight), and the activity units of the two enzymes used are: ml, pectinase activity 60,000 u / ml (both international standard units). Enzymolysis was stirred at 55°C for 72 hours. Then, heat the enzymatic hydrolyzate to 90° C. and keep the temperature for 30 minutes. After cooling, the enzymolyzate is concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com