Copper molybdenum separation flotation agent and using method thereof

A flotation agent, copper and molybdenum technology, applied in flotation, solid separation, etc., can solve the problems of chemical wastewater COD exceeding the standard, environmental problems, etc., achieve the effect of small impact, good effect, and reduce usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

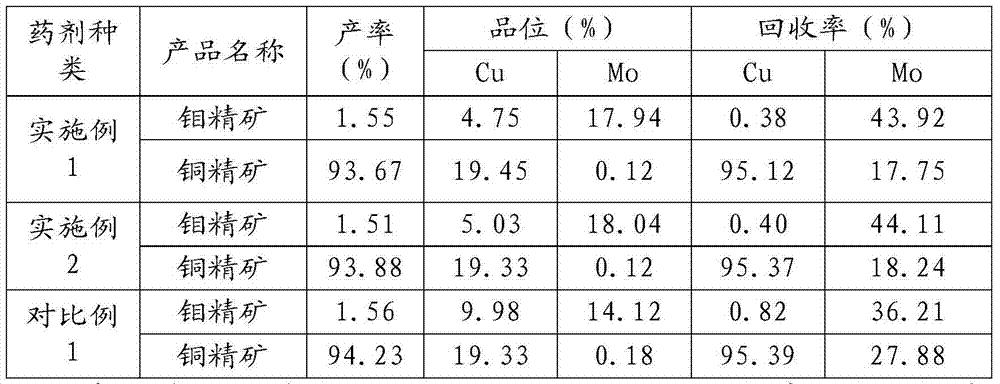

Embodiment 1

[0026] Carry out copper molybdenum separation to obtain the technological process of copper concentrate and molybdenum concentrate as follows:

[0027] (A) Prepare inhibitors and collectors respectively, wherein the inhibitors are prepared from the following components: 3kg of sodium carbonate, 3kg of sulfate, 10kg of copper compound, 15kg of sulfide, and 15kg of hydrosulfide;

[0028] The collector is prepared from the following components: 1 kg of oleic acid, 15 kg of 2-butyloctyl oleate, and 40 kg of petroleum cracking products.

[0029] (B) The raw ore is 100 tons of mixed flotation to get 3 tons of copper-molybdenum mixed concentrate slurry, and then 50kg inhibitor and 800g collector are added to 3 tons of copper-molybdenum mixed concentrate slurry for separation and roughing to obtain molybdenum rough concentrate 0.35 tons of pulp and 2.65 tons of copper coarse concentrate pulp, the liquid-solid mass ratio in the copper-molybdenum mixed concentrate pulp is 4:1, and the s...

Embodiment 2

[0033] Carry out copper molybdenum separation to obtain the technological process of copper concentrate and molybdenum concentrate as follows:

[0034] (A) Prepare inhibitors and collectors respectively, wherein the inhibitors are prepared from the following components: 5kg sodium carbonate, 5kg sulfate, 15kg copper compound, 20kg sulfide, 20kg hydrosulfide, and 650kg water;

[0035] The collector is prepared from the following components: 3kg of oleic acid, 25kg of 2-butyloctyl oleate, and 50kg of petroleum cracking products.

[0036] (B) 3 tons of copper-molybdenum mixed concentrate slurry is obtained from 100 tons of mixed flotation of raw ore, and 40kg of inhibitor and 1200g collector are added to 3 tons of copper-molybdenum mixed concentrate slurry for separation and roughing to obtain rough concentrate of molybdenum 0.40 tons of pulp and 2.60 tons of copper coarse concentrate pulp, the liquid-solid mass ratio in the copper-molybdenum mixed concentrate pulp is 6:1, and th...

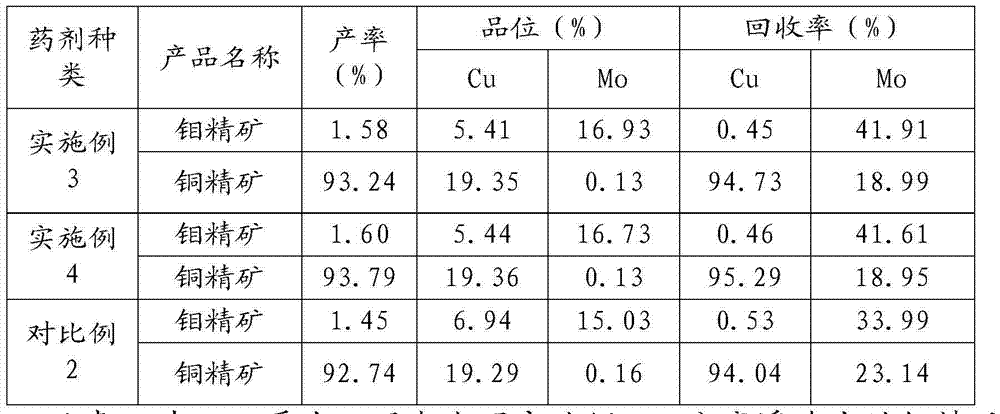

Embodiment 3

[0041] Carry out copper molybdenum separation to obtain the technological process of copper concentrate and molybdenum concentrate as follows:

[0042] (A) Prepare inhibitors and collectors respectively, wherein the inhibitors are prepared from the following components: sodium carbonate 4kg, sulfate 4kg, copper compound 12kg, sulfide 18kg, hydrosulfide 18kg, water 560kg;

[0043]The collector is prepared from the following components: 2kg of oleic acid, 20kg of 2-butyloctyl oleate, and 45kg of petroleum cracking products.

[0044] (B) The raw ore is 100 tons of mixed flotation to get 3 tons of copper-molybdenum mixed concentrate pulp, 46kg inhibitor and 1000g collector are added to 3 tons of copper-molybdenum mixed concentrate pulp for separation and roughing to obtain molybdenum coarse concentrate pulp 0.44 tons and 2.56 tons of copper coarse concentrate slurry, the liquid-solid mass ratio in the copper-molybdenum mixed concentrate slurry is 5:1, and the separation and roughi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com