Fabrication method for laminated-type secondary battery

A secondary battery and manufacturing method technology, applied in the direction of secondary batteries, batteries, battery pack components, etc., can solve the problems of shortening the forming cycle, shortening the production cycle, increasing costs, etc., and achieve the effect of promoting cooling and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

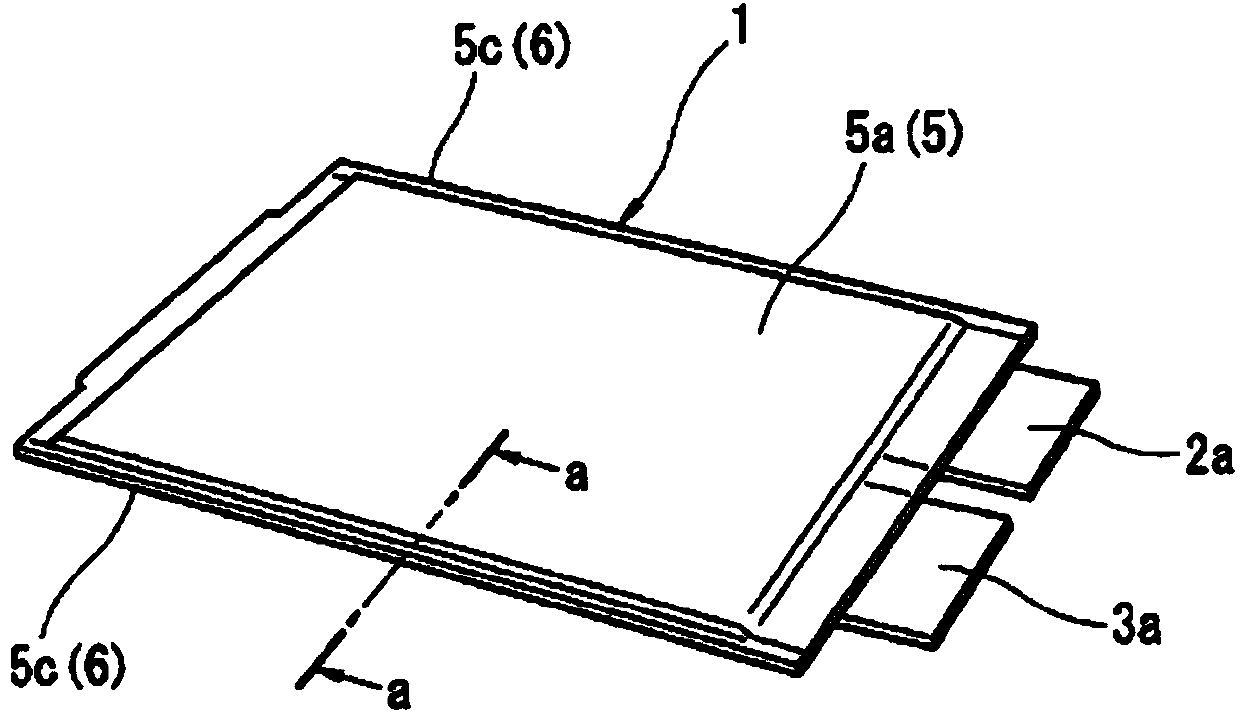

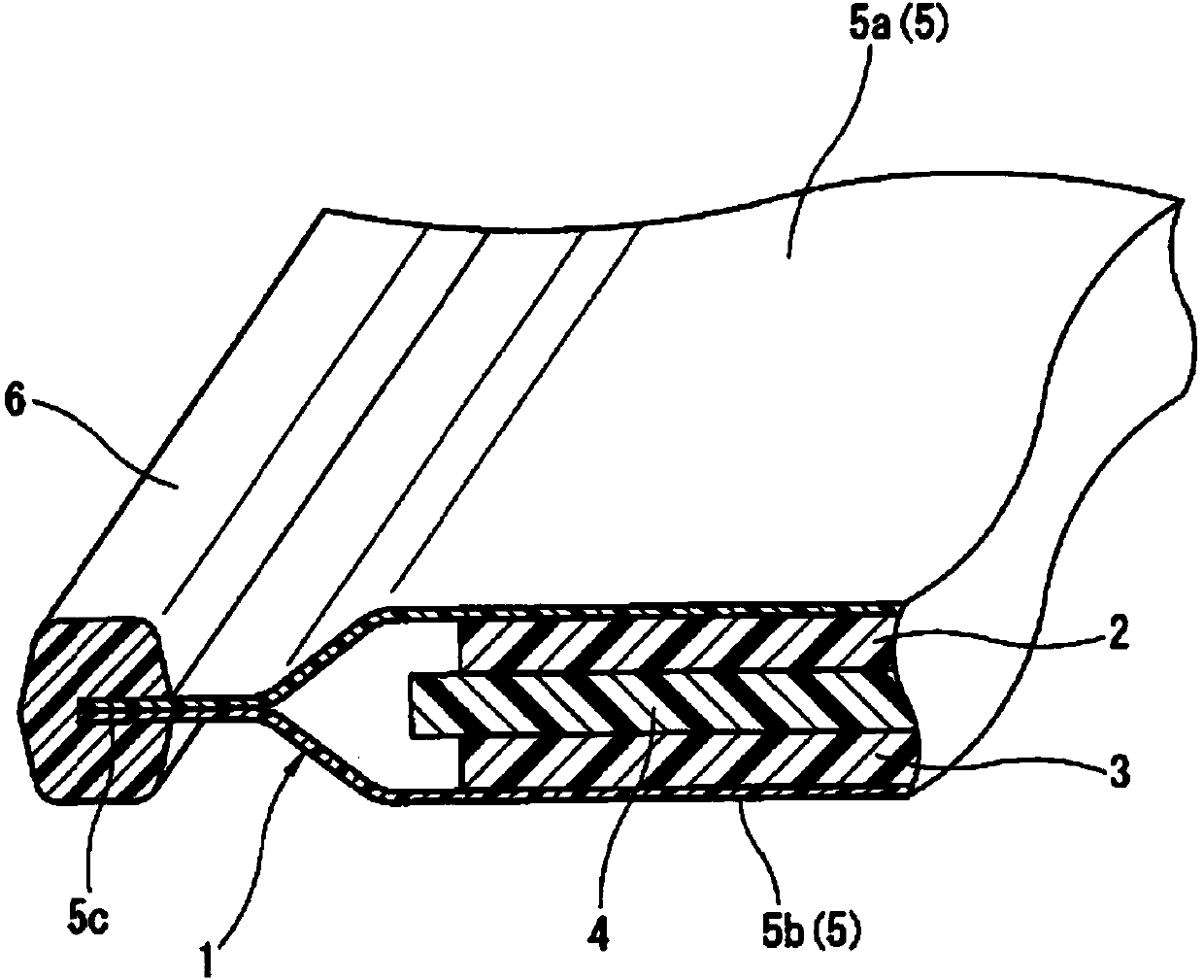

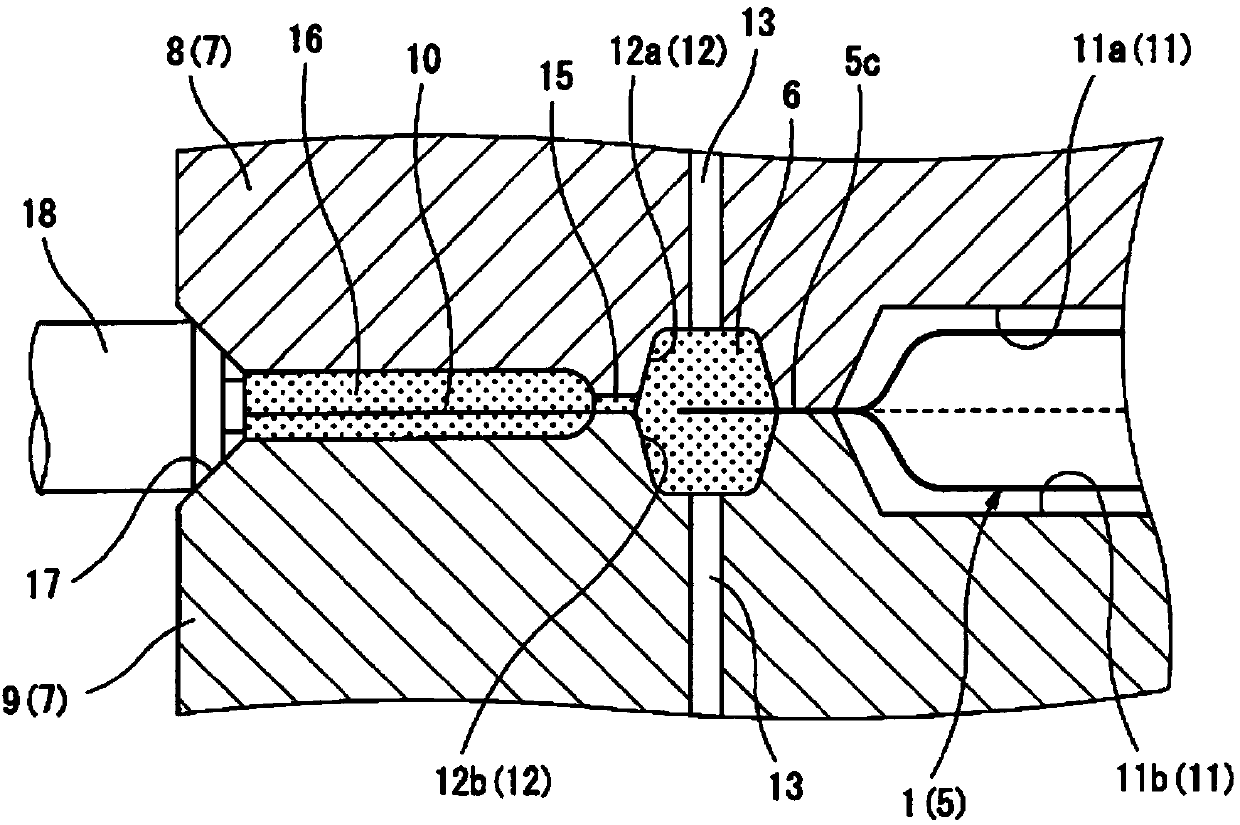

[0018] figure 1 The following drawings represent more specific embodiments for carrying out the present invention, especially figure 1 It shows the appearance shape of a thin laminated lithium ion secondary battery (hereinafter referred to as "battery") as an example of a laminated secondary battery to be manufactured, figure 2 yes means figure 1 An enlarged cross-sectional view along line a-a of . Furthermore, the battery described above is used, for example, as a battery cell of a lithium-ion storage battery for an electric vehicle.

[0019] Such as figure 1 , figure 2 As shown, the battery 1 is packaged by a rectangular-shaped laminated film outer case 5, and the laminated film outer case 5 is formed from upper and lower sides so that the positive terminal 2a and the negative terminal 3a protrude outward. Composed of laminated films 5a, 5b, the positive electrode 2, negative electrode 3, and separator 4 as battery elements are packaged inside the laminated film o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com