Three-core power line visual deconcentrating system detected by optical fiber sensor

A fiber optic sensor and power cord technology, applied in the direction of circuits, electrical components, circuit/collector components, etc., can solve the problems of power cord wiring errors, product scrapping, low efficiency, etc., and achieve the effect of preventing misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content, structural features, goals and effects of the present invention in detail, the following examples are given to describe the embodiments in conjunction with the accompanying drawings.

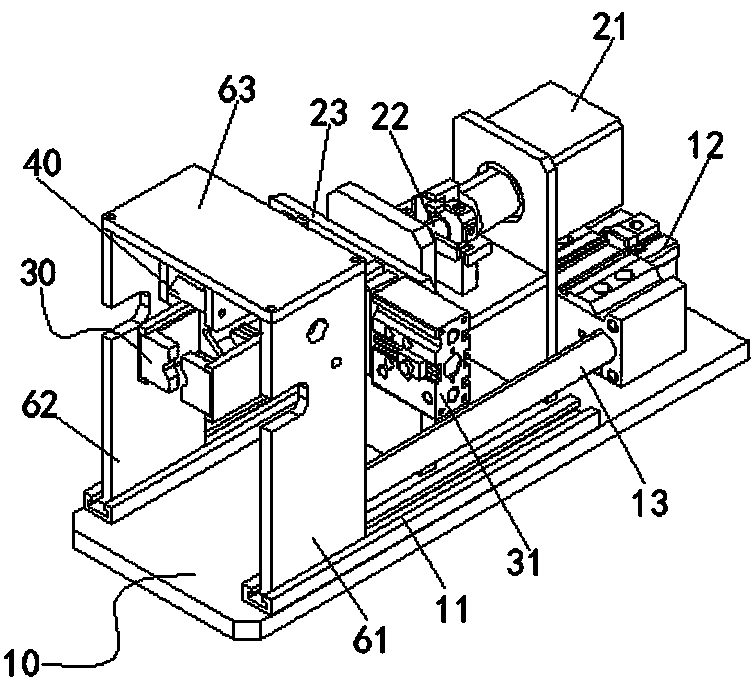

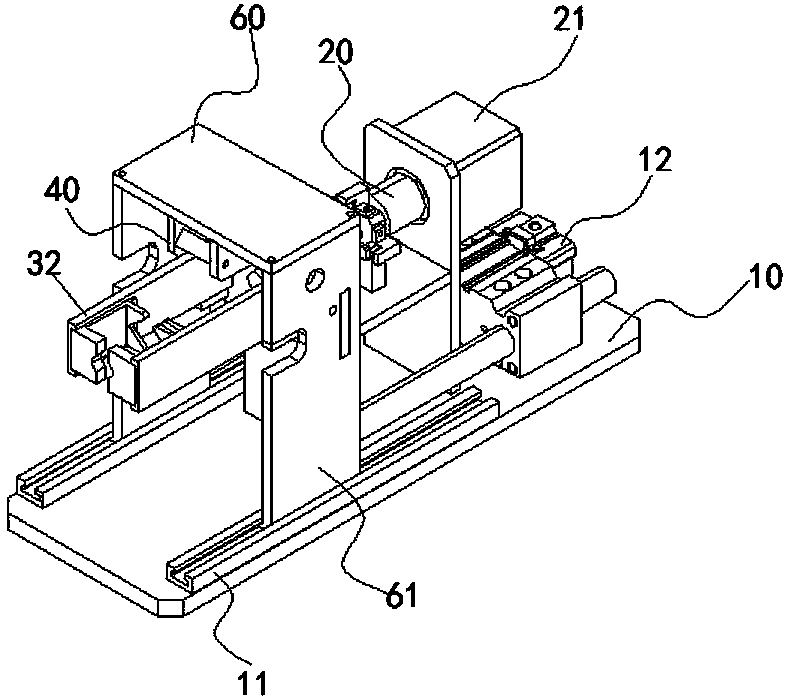

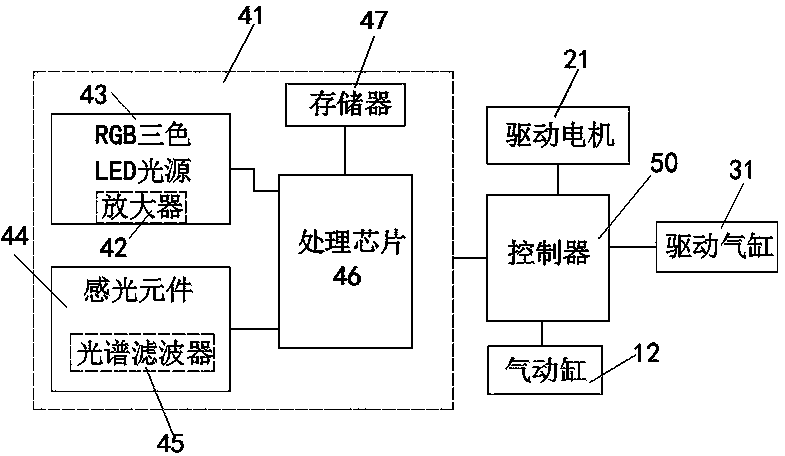

[0022] see figure 1 , and see in conjunction with figure 2 and image 3 As shown, the present invention provides a rotating device 20 using an optical fiber transmission 40, a clamping device 30 for clamping a power cord, a visual line divider 40 and a controller 50, and the clamping device 30 is fixedly installed on the rotating device 20 , and the rotating device 20 can drive the thread clamping device 30 to rotate. The rotating device 20 includes a drive motor 21 for driving the thread clamping device 30 to rotate. The drive motor 21 is electrically connected to the controller 50, wherein the bottom plate 10 Equipped with a mounting frame 60 for installing the visual line divider 40, the mounting frame 60 is movably arranged on the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com