Sintering method for rear earth tungsten electrode billets

A sintering method, rare earth tungsten technology, applied in the field of powder metallurgy, can solve the problems of reduced yield, large temperature gradient of tungsten billet, high sintering cost, etc., and achieve the effect of high yield and high efficiency physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

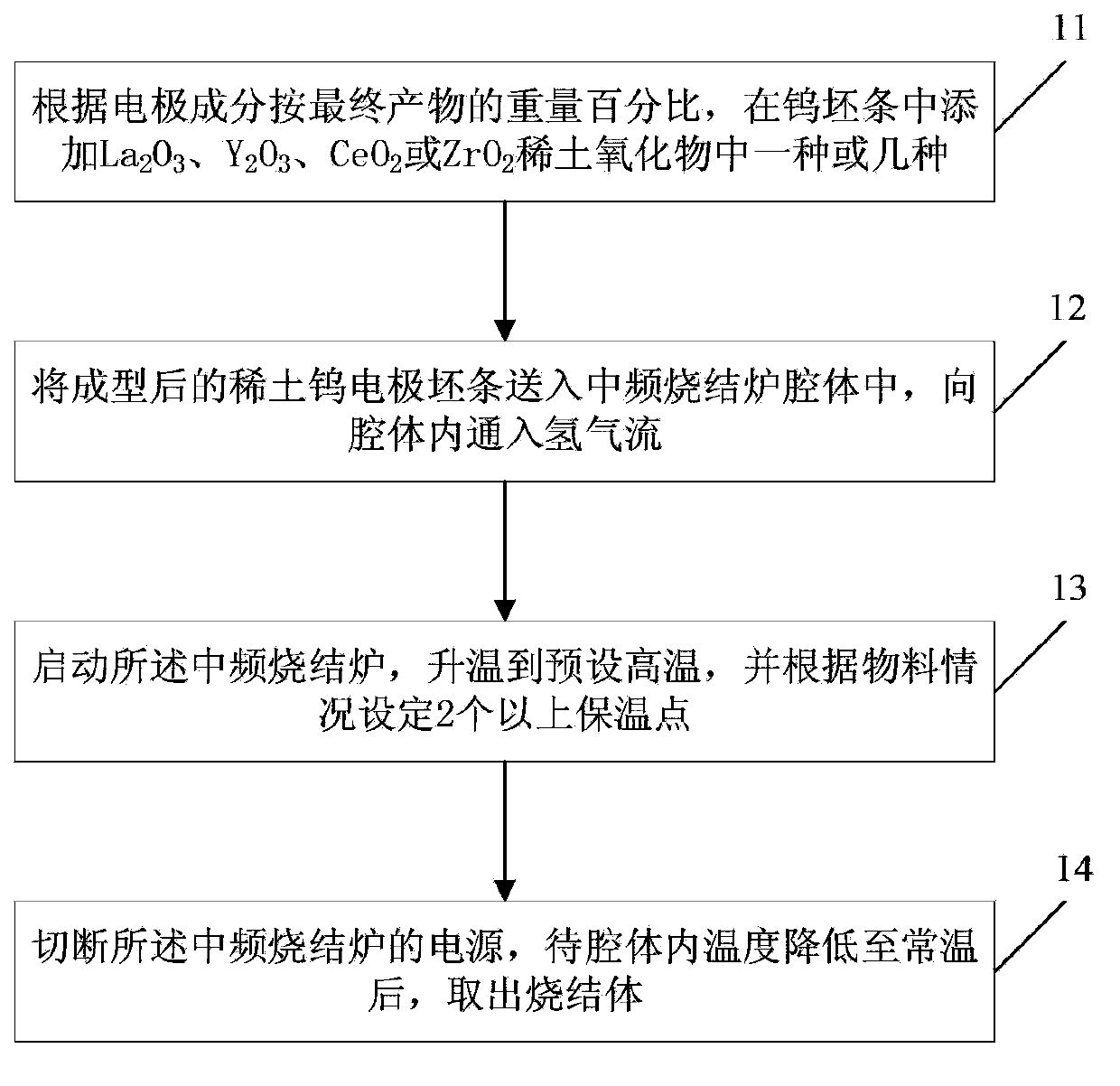

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: first La 2 o 3 The content is 1.5%, the weight after isostatic pressing is 500g, and the tungsten billet with a length of 200mm is sent into the cavity of the intermediate frequency induction furnace, and the hydrogen flow is introduced into the cavity; Raise the temperature at a rate of 1200°C, keep the temperature for 2 hours, continue to heat up to 2000°C, and keep the temperature for 4 hours; then cut off the power supply, and take out the sintered body after the temperature in the cavity reaches normal temperature.

Embodiment 2

[0029] Embodiment 2: at first CeO 2 The content is 2%, the weight after isostatic pressing is 1000g, and the tungsten billet with a length of 500mm is sent into the cavity of the intermediate frequency induction furnace, and the hydrogen flow is introduced into the cavity; Raise the temperature at a rate of 1400°C, keep it warm for 2 hours, continue to raise the temperature to 2400°C, and keep it warm for 2 hours; cut off the power supply, and take out the sintered body after the temperature in the cavity reaches normal temperature.

Embodiment 3

[0030] Embodiment 3: first La 2 o 3 , Y 2 o 3 , CeO 2 The total content of three kinds of rare earth oxides is 2.2%, the weight after isostatic pressing is 1500g, and the tungsten billet with a length of 400mm is sent into the cavity of the intermediate frequency induction furnace, and the hydrogen flow is introduced into the cavity; start the intermediate frequency sintering furnace , heat up at a rate of 200°C per hour, heat up to 1200°C, keep warm for 2 hours, continue to heat up to 2200°C, keep warm for 3 hours; cut off the power supply, and take out the sintered body after the temperature in the cavity reaches normal temperature.

[0031] According to the rare earth tungsten electrode billets obtained in the above three embodiments, the test density of the rare earth tungsten electrode billets obtained in the above three embodiments is shown in the following table:

[0032] Table 1

[0033]

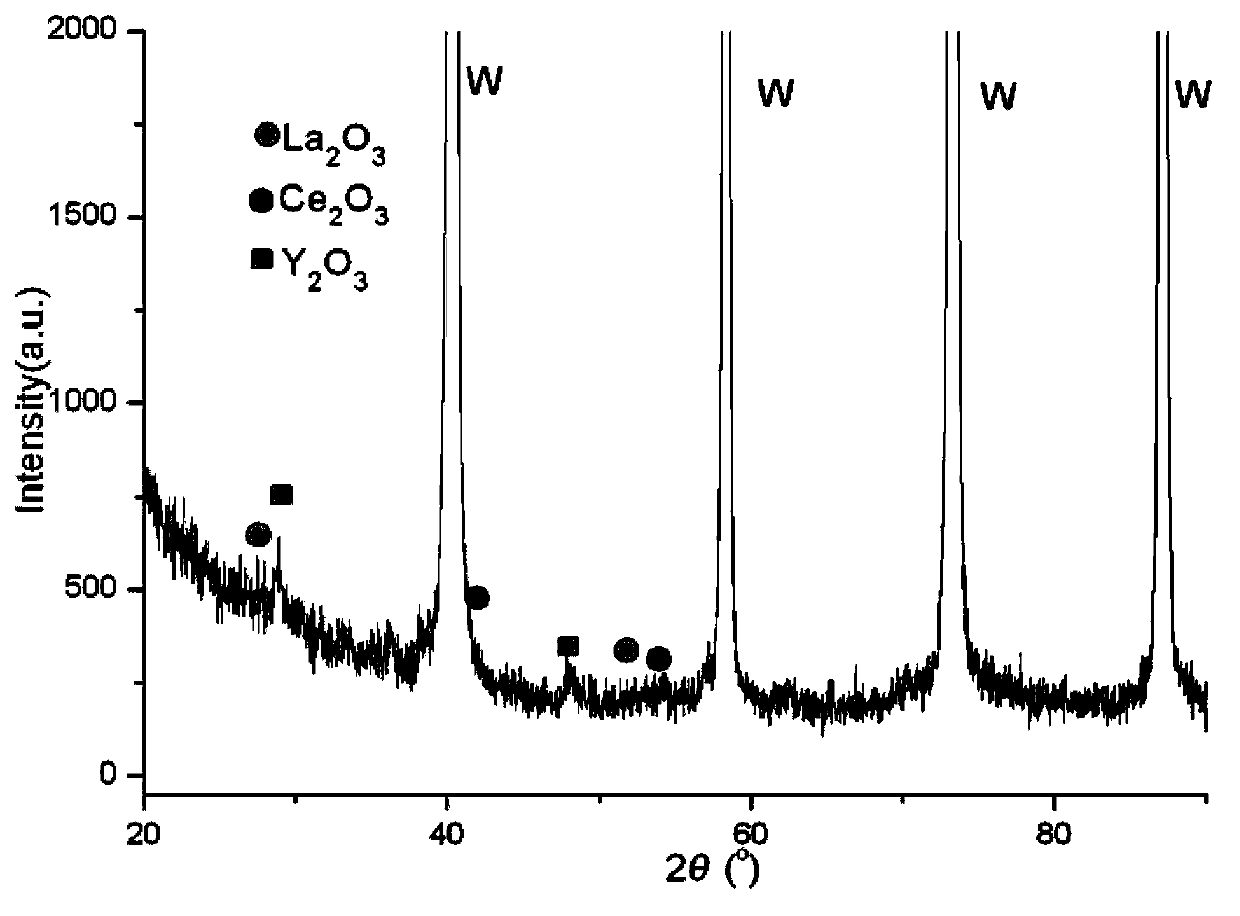

[0034] like figure 2 The schematic diagram of the XRD result of the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com