Recycling method of CdTe solar cell module

A technology of solar cells and recycling methods, applied in the direction of electronic waste recycling, recycling technology, chemical instruments and methods, etc., can solve the problems of easy pollution of ion exchange columns, low treatment efficiency of low-concentration acid etching solution, and blockage, and achieve easy Achieve amplification, avoid clogging, and simplify the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1) Immerse 1 kg of CdTe solar cell glass assembly from which the EVA encapsulant has been removed in an acid etching solution containing sulfuric acid and hydrogen peroxide. The equilibrium concentrations of Cd and Te after two acid etching were 2274ppm and 2720ppm, respectively. figure 1 shown.

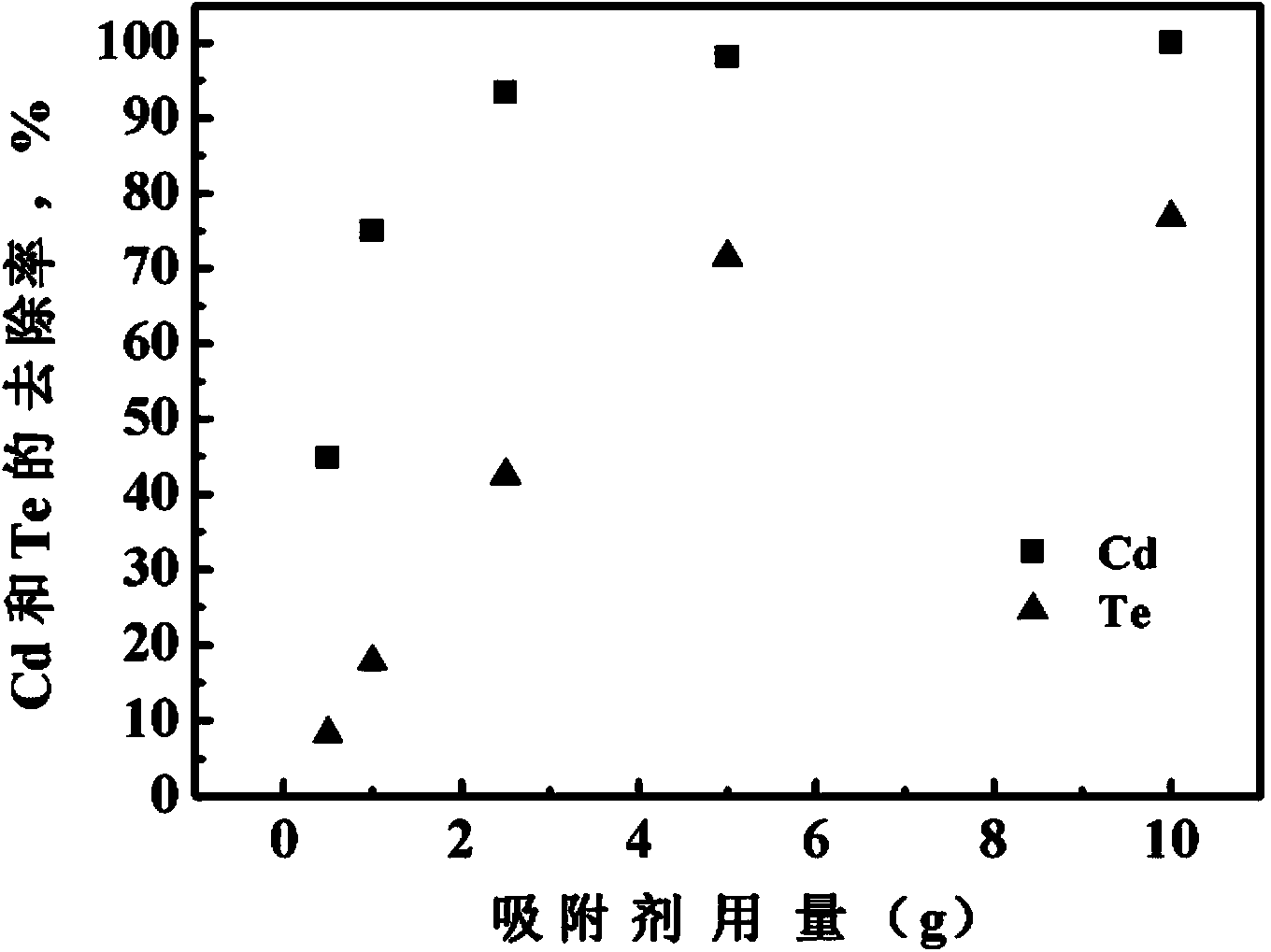

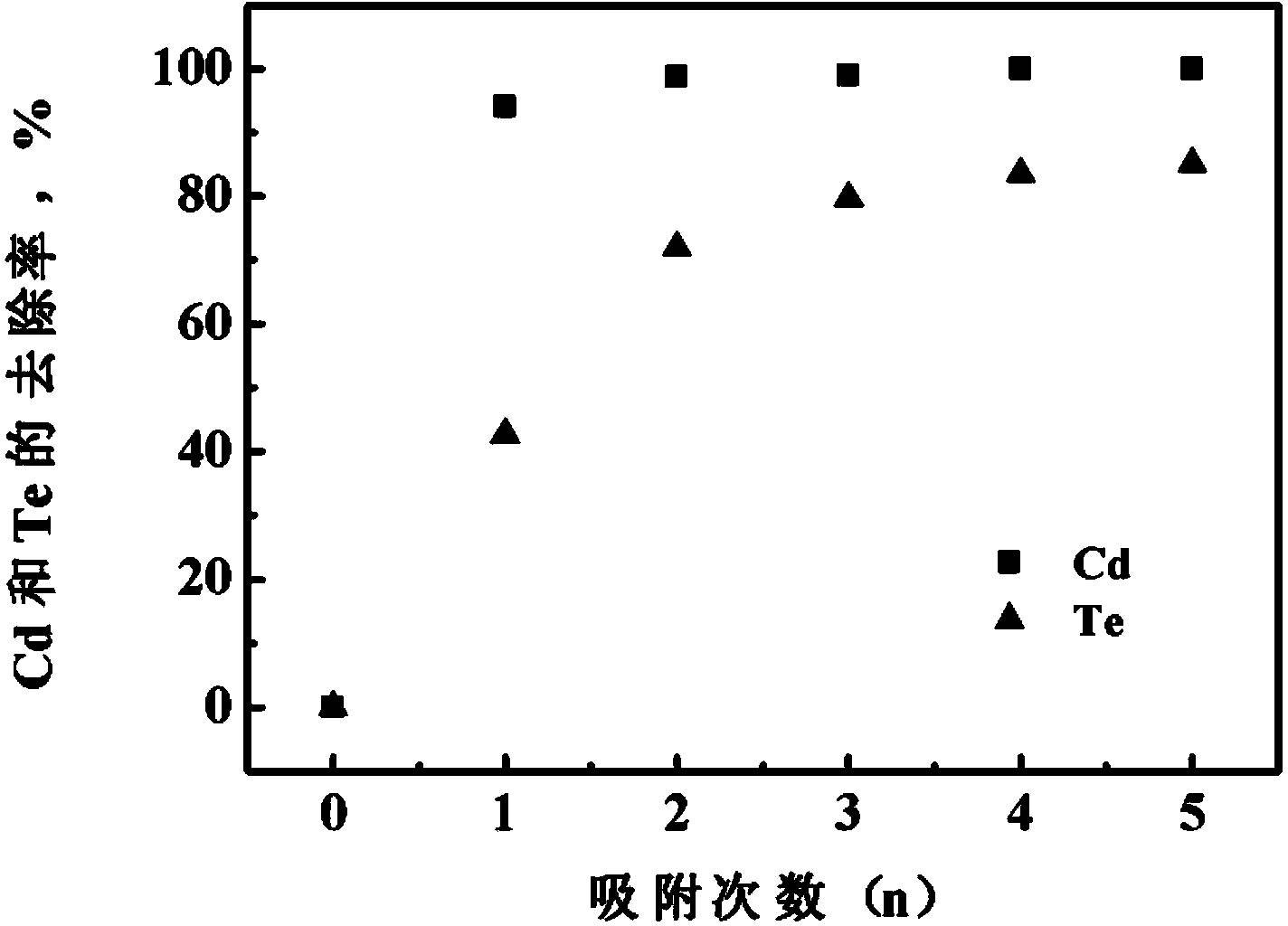

[0020] 2) Add the magnetic polymer microspheres into the secondary acid etching solution of CdTe, and after fully stirring for 10 minutes, use a magnetic separation device to separate the magnetic polymer microspheres whose surface has adsorbed Cd and Te elements. Investigating the removal ability of magnetic polymer microspheres to Cd and Te in 5mL CdTe secondary acid etching solution, it can be seen that: with the increase of the amount of adsorbent, the removal rate of Cd and Te is significantly improved; 100% Cd and 80% Te can be adsorbed separate, see figure 2 shown. After diluting the 5mL CdTe secondary acid etching solution 5 times with deionized water, add 2.5g mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com