Polygeneration system and method for refractory iron ore magnetization roasting

A magnetic roasting and iron ore technology, which is applied in the polygeneration system field of magnetic roasting of refractory iron ore, can solve the problems of long roasting time, slow heat and mass transfer speed, large ore feeding granularity, etc., to improve the comprehensive Utilization rate, pollution avoidance, effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

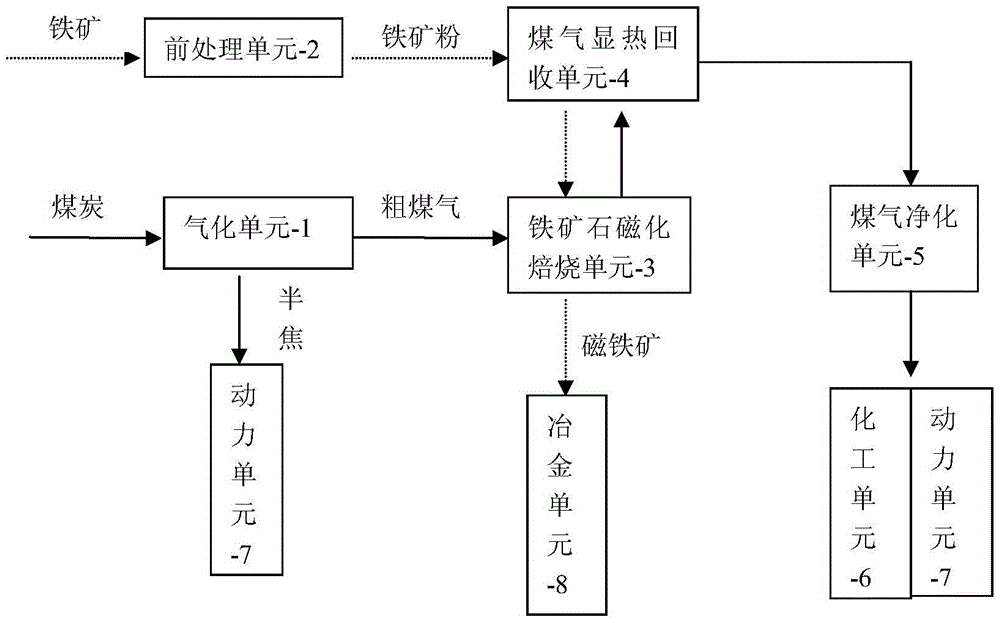

[0036] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings.

[0037] figure 1 The structure diagram of the metallurgy, chemical industry and power polygeneration system of refractory iron ore magnetization roasting provided by the present invention, the system includes gasification unit 1, iron ore pretreatment unit 2, iron ore magnetization roasting unit 3, coal gas Sensible heat recovery unit 4, gas purification unit 5, chemical industry unit 6, power unit 7, and metallurgy unit 8. The power unit includes a gas-fired power generation unit that gasifies coal gas, and also includes a semi-coke coal-fired power generation unit.

[0038] The gasification unit 1 is used to partially gasify coal in the gasifier to produce raw gas, and output the obtained raw gas to the iron ore magnetization roasting unit 3 as reducing roasting g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com