Preparation method of fluorinated acrylate emulsion

A technology of fluorine-containing alkyl acrylic acid and acrylate, which is applied in the direction of coating, etc., can solve the problems of latex particle collision coagulation, polymer film water resistance decline, etc., and achieve narrow particle size distribution, excellent chemical resistance, and excellent storage stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

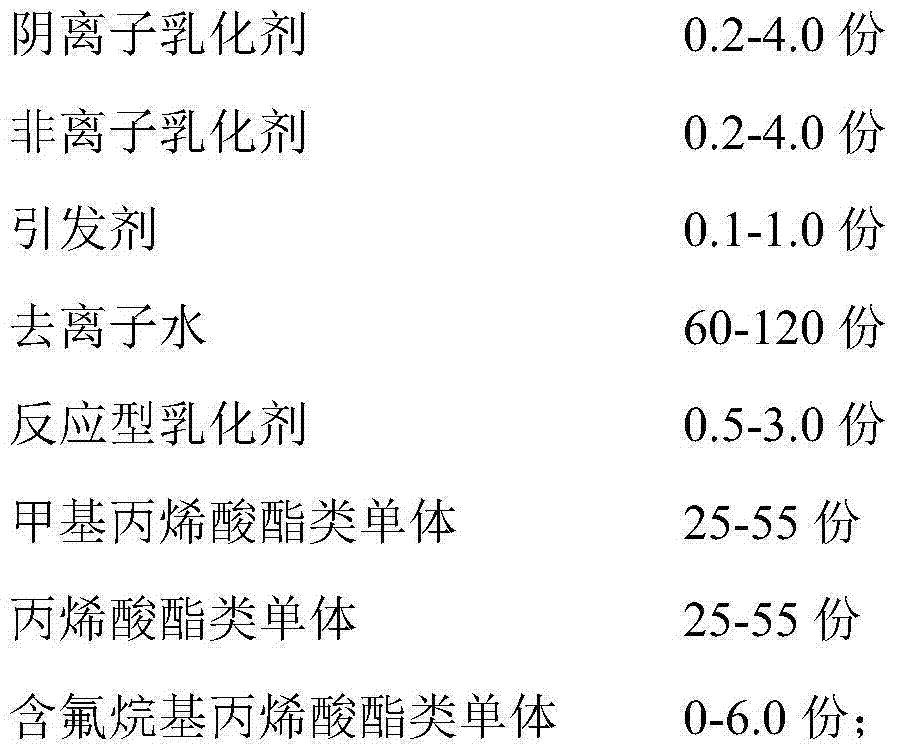

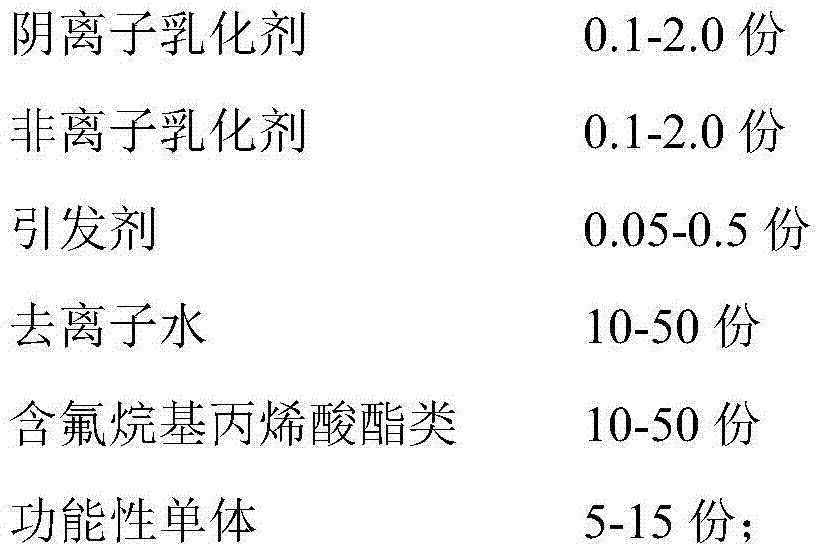

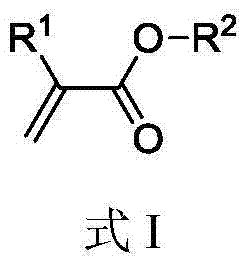

Method used

Image

Examples

Embodiment 1

[0040] Deionized water 125.0g, sodium lauryl sulfate 1.0g, octylphenol polyoxyethylene ether 2.0g, 2-propenyl ether-3-hydroxypropane-1-sodium sulfonate 1.5g, potassium persulfate 0.5g After stirring and dissolving, slowly add a mixture of 58.0 g of methyl methacrylate and 58.0 g of butyl acrylate, and perform pre-emulsification with high-speed mechanical stirring for 45 minutes to obtain 246.0 g of pre-emulsion I;

[0041] After stirring and dissolving 53.0g of deionized water, 0.4g of sodium lauryl sulfate, 0.8g of octylphenol polyoxyethylene ether, and 0.25g of potassium persulfate, slowly add 40.0g of trifluoroethyl methacrylate and methacrylic acid The mixed solution of 7.5 g of hydroxyethyl ester was pre-emulsified with high-speed mechanical stirring for 30 minutes to obtain 93.7 g of pre-emulsion II.

[0042]While maintaining the nitrogen atmosphere of the reaction device, take 80.0 g of pre-emulsion I, stir at 200 rpm, turn on the condensed water, and heat up to 80°C. ...

Embodiment 2

[0045] Stir 340.0g of deionized water, 4.8g of sodium dodecylbenzenesulfonate, 4.8g of fatty alcohol polyoxyethylene ether, 6.4g of 2-acrylamide-2-methylpropanesulfonic acid sodium salt, and 2.25g of potassium persulfate After dissolving, slowly add a mixture of 170.0 g of ethyl methacrylate, 138.0 g of ethyl acrylate and 22.0 g of hexafluorobutyl acrylate, and perform pre-emulsification with high-speed mechanical stirring for 1 hour to obtain 666.25 g of pre-emulsion I.

[0046] After stirring and dissolving 70 g of deionized water, 0.68 g of sodium dodecylbenzenesulfonate, 1.36 g of fatty alcohol polyoxyethylene ether, and 1.0 g of potassium persulfate, slowly add 58.0 g of hexafluorobutyl acrylate and 19.2 g of methacrylonitrile g of the mixed solution was pre-emulsified with high-speed mechanical agitation for 45 minutes to obtain 149.24 g of pre-emulsion II.

[0047] In the nitrogen atmosphere of the reaction device, 225.0 g of the pre-emulsion I was taken, stirred at 250...

Embodiment 3

[0050] 165.0g of deionized water, 1.6g of disodium 1,2-dodecyl diether disulfonate, 2.0g of nonylphenol polyoxyethylene ether, 2.2g of alkylphenol allyl polyether sulfate, persulfuric acid After stirring and dissolving 1.35 g of sodium, slowly add a mixture of 70.0 g of butyl methacrylate, 90.0 g of hexadecyl acrylate and 10.0 g of trifluorooctyl acrylate, and pre-emulsify with high-speed mechanical stirring for 30 minutes to obtain 332.15 g of pre-emulsion I.

[0051] After stirring and dissolving 40.0g of deionized water, 0.7g of disodium 1,2-dodecyl diether disulfonate, 0.7g of nonylphenol polyoxyethylene ether, and 0.40g of sodium persulfate, slowly add tridecafluoroacrylate A mixture of 28.0 g of octyl ester, 8.5 g of N-methylolacrylamide and 3.0 g of methacrylic acid was pre-emulsified with high-speed mechanical stirring for 45 minutes to obtain 80.9 g of pre-emulsion II.

[0052] In the nitrogen atmosphere of the reaction device, 100.0 g of the pre-emulsion I was taken...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com