A kind of ultraviolet light stabilizer based on polyvinyl chloride and preparation method thereof

A technology of ultraviolet light and stabilizer, which is applied in the field of polyvinyl chloride-based ultraviolet light stabilizer and its preparation, can solve the problems of non-uniform dispersion, decreased mechanical properties of polymers, and easy volatilization, etc., and achieves easy large-scale industrial production, The effect of avoiding environmental pollution problems and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

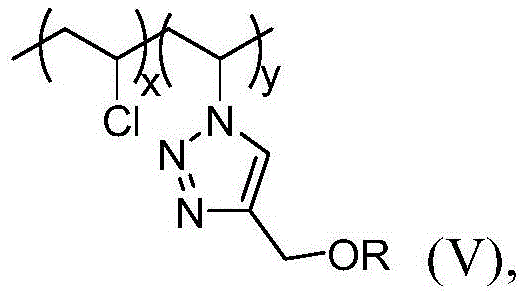

[0084] The preparation method of ultraviolet stabilizer of the present invention comprises the following steps:

[0085]

[0086] (i) providing a compound of formula 1 and a compound of formula 3, wherein,

[0087] Polyvinyl chloride and sodium azide react under the effect of a phase transfer catalyst to obtain a compound of formula 1,

[0088] Formula 2 compound and 2-bromopropyne reflux reaction under the effect of alkali to obtain formula 3 compound;

[0089]

[0090] (ii) the compound of formula 1 reacts with the compound of formula 3 to obtain the UV light stabilizer shown in formula V,

[0091] Among them, n=x+y;

[0092] x, y and R are defined as previously described.

[0093] The phase transfer catalyst is selected from the group consisting of tetrabutylammonium bromide, tetra-n-octylammonium bromide and benzyltriethylammonium chloride.

[0094] In another preferred example, the molar ratio of polyvinyl chloride, sodium azide and phase transfer catalyst is 1:...

Embodiment 1

[0126] Synthesis of azide-substituted polyvinyl chloride (compound of formula 1)

[0127]

[0128] Add polyvinyl chloride (3g, 0.14mmol, number average molecular weight is 22000g / mol), sodium azide (3.8g, 58.46mmol), tetrabutylammonium bromide (0.77g, 2.38mmol) and 30mL THF was reacted at 50°C for different times, as shown in Table 1.

[0129] After stopping the reaction, precipitate in methanol and dry to obtain white polyvinyl chloride powders with different azide molar substitution ratios.

[0130] 1 HNMR, (ppm): 2.0, 4.0, 4.5.

[0131] The results of the azide molar substitution ratio y / n at different reaction times are shown in Table 1.

[0132] The result of the azide molar substitution ratio y / n of different reaction times in table 1

[0133] Compound No. of Product Formula 1

[0134] *Note: Product number 1-1 refers to the compound of formula 1 corresponding to the reaction time of 6 hours, and so on.

Embodiment 2

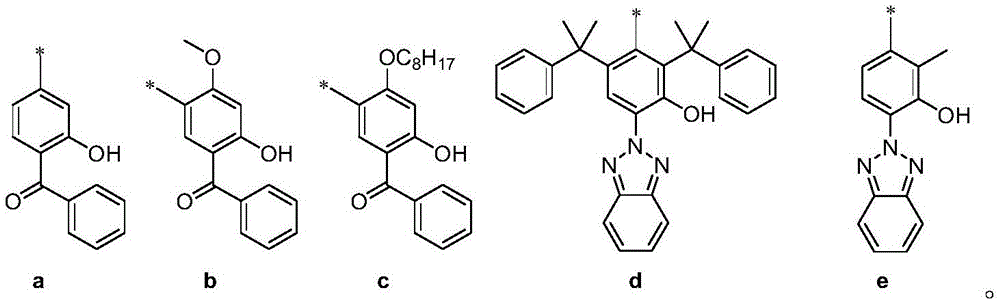

[0136] Synthesis of Alkyne Substituted Ultraviolet Light Antiseptic (Compound of Formula 3)

[0137]

[0138]

[0139] Add ultraviolet absorber (compound of formula 2) (10mmol), potassium carbonate (2.8g, 20mmol), 3-bromopropyne (0.8mL, 11mmol) and 25mL acetone into the reaction flask, and reflux for 24 hours. Stop the reaction, and perform flash column chromatography to obtain an alkynyl-substituted ultraviolet absorber (compound of formula 3). The reaction results are shown in Table 2.

[0140] Table 2 embodiment 2 reaction result

[0141]

[0142] * Note: product number 3a refers to the compound of formula 3 where R is corresponding to formula a, and so on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com