Solid-phase synthesis method for liraglutide

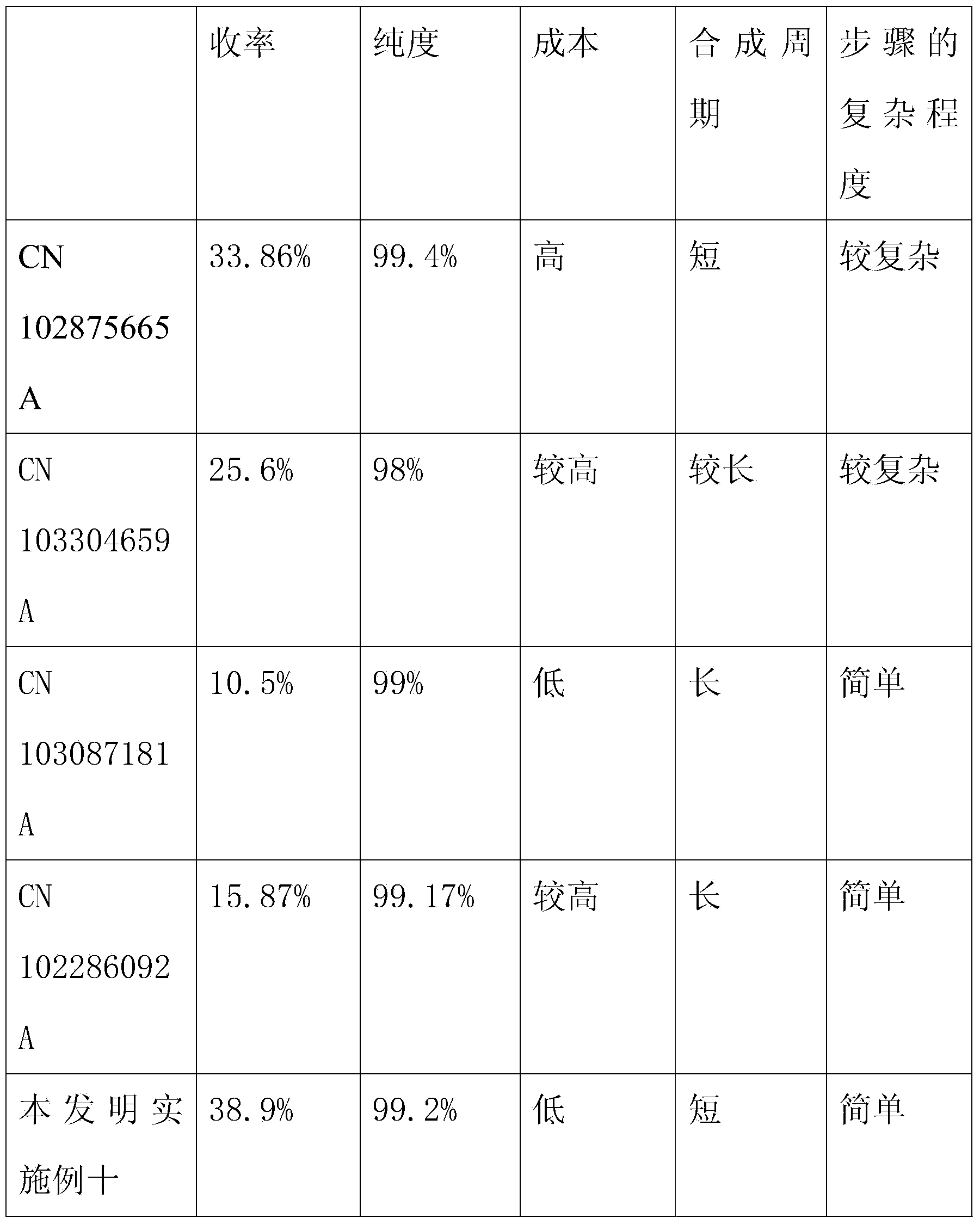

A technology of liraglutide and solid-phase synthesis, which is applied to the preparation method of peptides, chemical instruments and methods, peptides, etc., can solve the problems of many fragments, large resin consumption, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: Synthesis of Fragment 1

[0057] Weigh 10g of Wang resin with a substitution degree of 1.08mmol / g, add it to a solid-phase reaction column, and swell the resin with DMF for 30 minutes, weigh 3.21g Fmoc-Gly-OH, 1.46gHOBt and 0.13gDMAP and dissolve them with DMF, add 1.84 mL of DIC was activated for 5 minutes, and added to the above-mentioned reaction column filled with resin. After 3 hours of reaction, 20 mL of pyridine and 20 mL of acetic anhydride were added to block for 8 hours. Washed 6 times with DMF and 2 times with methanol, the detection substitution degree was 0.35mmol / g.

[0058] Use 25% piperidine / DMF to remove FMOC in FMOC-Gly-King resin, 10 minutes each time, twice in total, and wash with DMF 6 times after deprotection. , weigh

[0059] Fmoc-Arg(Pbf)-OH6.81g, HOBt1.42g, dissolved in 40ml of DMF, added DIC1.63ml to activate for 5 minutes, added to the reaction column for 2 hours to obtain

[0060] Fmoc-Arg(Pbf)-Gly-Wang resin. Repeat the ste...

Embodiment 2

[0062] Embodiment 2: the synthesis of fragment 2

[0063] Weigh 20g of CTC resin with a substitution degree of 1.0mmol / g, add it to a solid-phase reaction column, swell the resin with DMF for 30 minutes, dissolve 12.44g of Fmoc-Ala-OH with DMF, add 26.4mL of DIEA to activate, add the above In the reaction column equipped with the resin, after reacting for 2 hours, 20 mL of anhydrous methanol was added to block for 1 hour, and washed 6 times with DMF to obtain Fmoc-Ala-CTC.

[0064] Use 25% piperidine / DMF to remove FMOC in Fmoc-Ala-CTC, 10 minutes each time, twice in total, and wash 6 times with DMF after deprotection. , Weighed Fmoc-Ala-OH18.68g, HOBt8.1g, dissolved in 80ml DMF, added DIC9.3ml to activate for 5 minutes, added to the reaction column and reacted for 2 hours to obtain Fmoc-Ala-Ala-CTC. Repeat the above steps of de-FMOC and amino acid coupling, followed by Fmoc-Gln(trt)-OH, Fmoc-Gly-OH, Fmoc-Glu(Otbu)-OH, Fmoc-Leu-OH, Fmoc-Tyr(tbu)- OH, Fmoc-Ser(tbu)-OH, Fmoc-Se...

Embodiment 3

[0067] Embodiment 3: the synthesis of fragment 2

[0068]Weigh 20g of CTC resin with a substitution degree of 1.0mmol / g, add it to a solid-phase reaction column, swell the resin with DMF for 30 minutes, dissolve 12.44g of Fmoc-Ala-OH with DMF, add 26.4mL of DIEA to activate, add the above In the reaction column equipped with the resin, after reacting for 2 hours, 20 mL of anhydrous methanol was added to block for 1 hour, and washed 6 times with DMF to obtain Fmoc-Ala-CTC.

[0069] Use 25% piperidine / DMF to remove FMOC in Fmoc-Ala-CTC, 10 minutes each time, twice in total, and wash 6 times with DMF after deprotection. , Weighed Fmoc-Ala-OH18.68g, TBTU19.26g, dissolved in 80ml DMF, added DIEA19.8ml to activate for 5 minutes, added to the reaction column and reacted for 2 hours to obtain Fmoc-Ala-Ala-CTC. Repeat the above steps of de-FMOC and amino acid coupling, followed by Fmoc-Gln(trt)-OH, Fmoc-Gly-OH, Fmoc-Glu(Otbu)-OH, Fmoc-Leu-OH, Fmoc-Tyr(tbu)- OH, Fmoc-Ser(tbu)-OH, Fmoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com