Technology for treating inorganic fluorine-organic fluorine industrial waste water

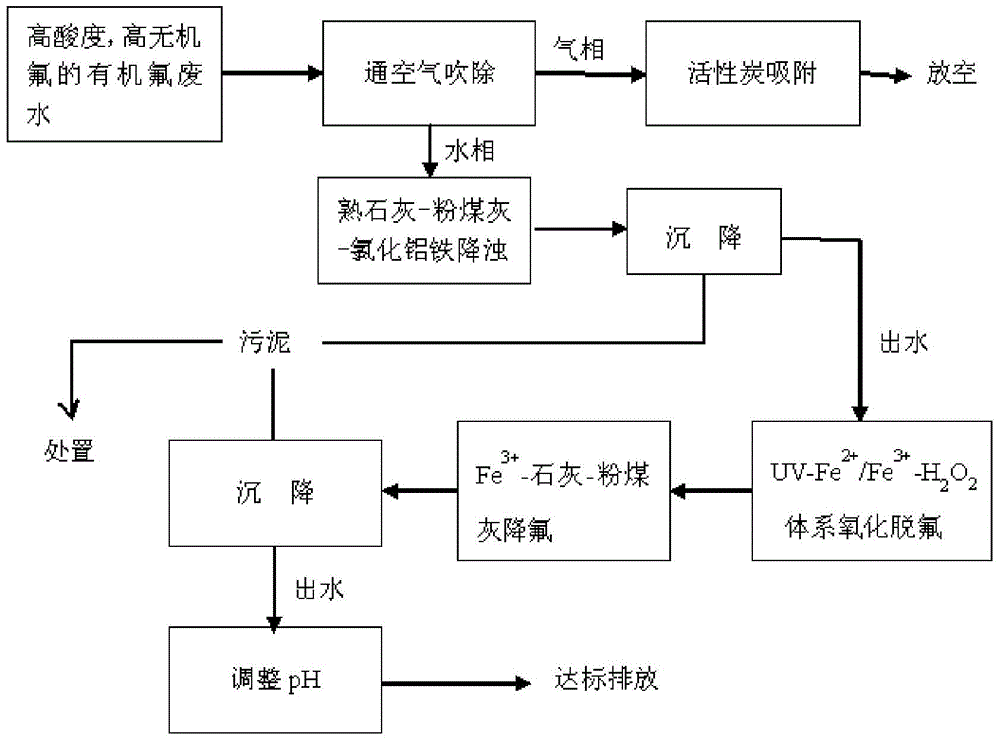

A technology for industrial wastewater and organic fluorine, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc. To achieve the effect of cost saving, load reduction and consumption saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] 1) According to the conventional process, air is introduced into the industrial wastewater containing high concentration of inorganic fluorine-organic fluorine to blow off volatile substances, and the waste water after volatile matter removal is obtained; after measurement, the waste water after volatile matter removal is low-turbidity waste water; collect The escaped gas can be directly discharged after being adsorbed by the activated carbon adsorption column;

[0067] 2) UV-Fe 2+ / Fe 3+ - Oxidative defluorination of hydrogen peroxide system

[0068] Press Fe 2+ with Fe 3+ The molar ratio of the substance is 1:4, ferric sulfate and ferrous sulfate are dissolved in the sulfuric acid solution of pH=2, obtain the mixed solution of ferric sulfate and ferrous sulfate, namely obtain the Fe-containing 2+ / Fe 3+ solutions of mixed ions;

[0069] Using a 185nm-254nm ultraviolet lamp as a light source, first adjust the pH value of the wastewater after removing volatiles, t...

Embodiment 2

[0073] 1) According to the conventional process, air is introduced into the industrial wastewater containing high concentration of inorganic fluorine-organic fluorine to blow off volatile substances, and the waste water after volatile matter removal is obtained; after measurement, the waste water after volatile matter removal is low-turbidity waste water; collect The escaped gas can be directly discharged after being adsorbed by the activated carbon adsorption column;

[0074] 2) UV-Fe 2+ / Fe 3+ - Oxidative defluorination of hydrogen peroxide system

[0075] Press Fe 2+ with Fe 3+ The molar ratio of the substance is 2:3, dissolving ferric nitrate and ferrous nitrate in the sulfuric acid solution of pH=2, obtains the mixed solution of ferric nitrate and ferrous nitrate, promptly obtains Fe-containing 2+ / Fe 3+ solutions of mixed ions;

[0076] Using a 185nm-254nm ultraviolet lamp as the light source, first adjust the pH value of the wastewater after removing volatiles, th...

Embodiment 3

[0080] 1) According to the conventional process, air is introduced into the industrial wastewater containing high concentration of inorganic fluorine-organic fluorine to blow off volatile substances, and the waste water after volatile matter removal is obtained; after measurement, the waste water after volatile matter removal is low-turbidity waste water; collect The escaped gas can be directly discharged through the adsorption of activated carbon adsorption column;

[0081] 2) UV-Fe 2+ / Fe 3+ - Oxidative defluorination of hydrogen peroxide system

[0082] Press Fe 2+ with Fe 3+ The molar ratio of the substance is 1:2, and ferric ammonium sulfate and ferrous ammonium sulfate are dissolved in the sulfuric acid solution of pH=2 to obtain a mixed solution of ferric ammonium sulfate and ferrous ammonium sulfate, that is, to obtain Fe-containing ammonium 2+ / Fe 3+ solutions of mixed ions;

[0083] Using a 185nm-254nm ultraviolet lamp as the light source, first adjust the pH v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com