Dry and wet type cyclic magnetic separation method

A dry-wet type, magnetic separation technology, applied in the field of magnetic separation, can solve the problems of large footprint, inconvenient management, and long process, and achieve the effect of small footprint, easy management, and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

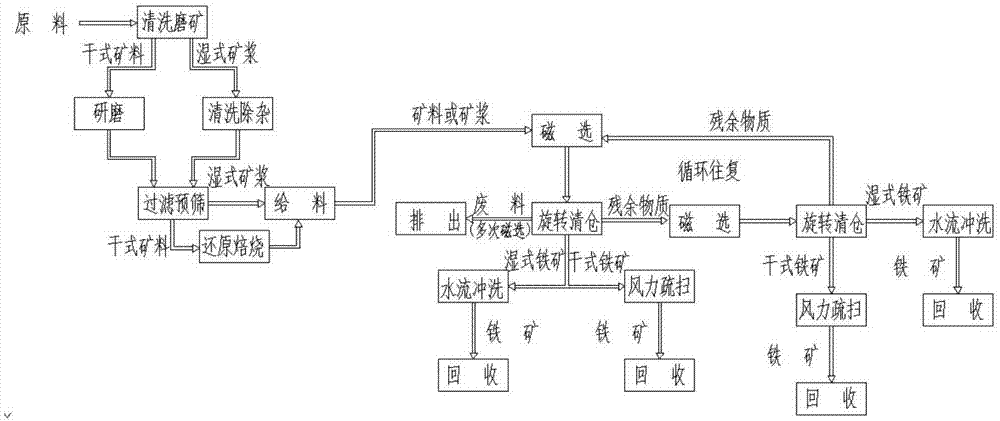

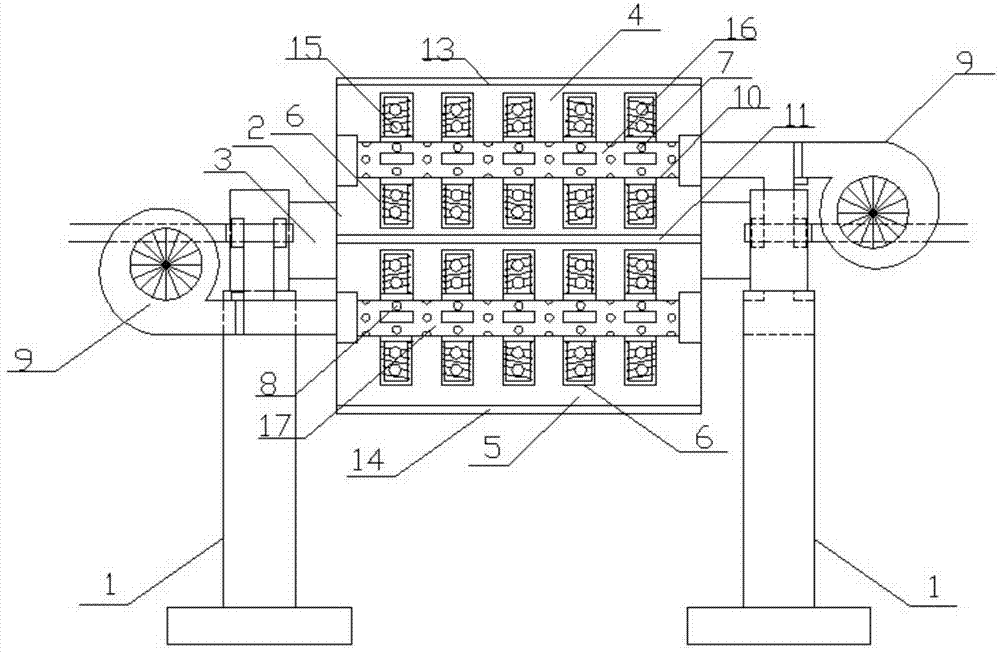

[0031] Referring to the accompanying drawings, a dry-wet circulating magnetic separation method includes the following steps:

[0032] 1) Grinding, cleaning and removing impurities. If it is dry ore, the ore should be put into a ball mill, and at least 80% of the mineral particle size is less than 0.08mm. If it is a wet slurry, it should be cleaned and removed first. The visible impurity content in the pulp should be controlled below 10%;

[0033] 2) Filter and pre-screen, pass the mineral material or pulp through the 60-400 mesh sieve in advance, and select the finer particle mineral powder or pulp;

[0034] 3), reduction roasting, for dry ore, the roasting temperature is 700-750 ℃, the added weight of reducing agent is 13-15% of the dry ore, and the roasting time is 70-90 minutes, so that the weak magnetic iron minerals become Strong magnetic magnetite;

[0035] 4) Feeding, inject the mixed mineral material or mixed pulp into the magnetic separator;

[0036] 5) Magnetic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com