High accuracy (resistance-capacitance) RC calibration circuit

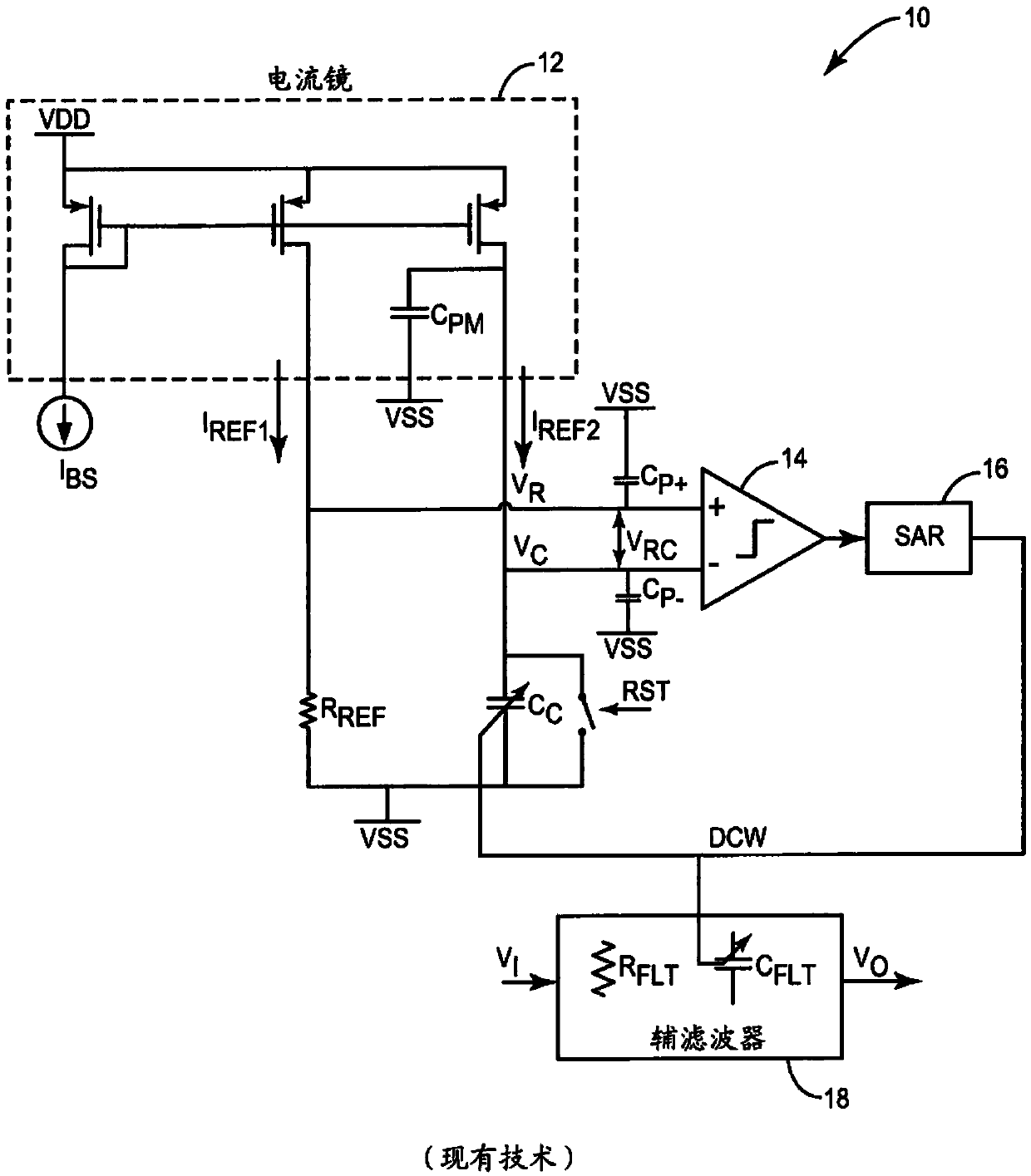

A resistance-capacitor, calibration circuit technology, applied in impedance networks, electrical components, multi-terminal-pair networks, etc., can solve the problems of RC time constant calibration error, calibration error, RC calibration circuit 10 can not be optimized and high calibration accuracy, etc., to ensure Current matching performance, effect of eliminating current source matching requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] figure 2 A functional schematic diagram of the RC calibration circuit 20 according to one embodiment of the present invention is depicted. In this embodiment, a current steering structure is implemented to remove current sources matching requirements. Compared with the conventional RC calibration circuit 10, figure 2 The circuit in 20 generates V from the same current source M1 R and V C , so the structure ensures excellent current matching performance.

[0026] During the initial reset phase, the RC calibration circuit 20 precharges the parasitic capacitance to I REF *R REF . This process will cancel out the parasitic capacitance, which eliminates the connection with the parasitic capacitance C at the output of the current source PM and the loading capacitance C from the comparator input P associated loss of precision. This is described more fully in this article.

[0027] Such as figure 2 The illustrated RC calibration circuit 20 according to one embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com