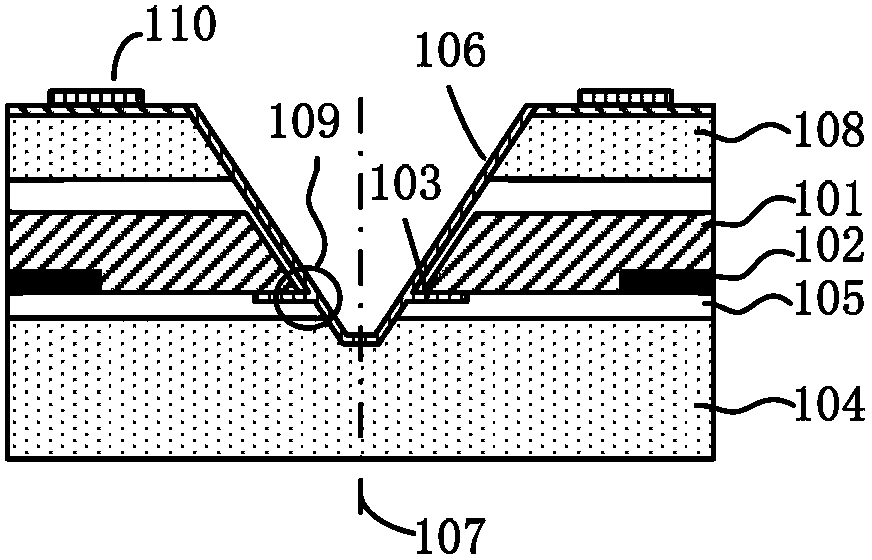

Wafer level packaging method and packaging structure for image sensor

A wafer-level packaging and image sensor technology, applied in radiation control devices, etc., can solve problems such as poor reliability of T-shaped connections, radiation damage to devices, and large capacitance values, and overcome poor reliability, small signal delay, and small capacitance. value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

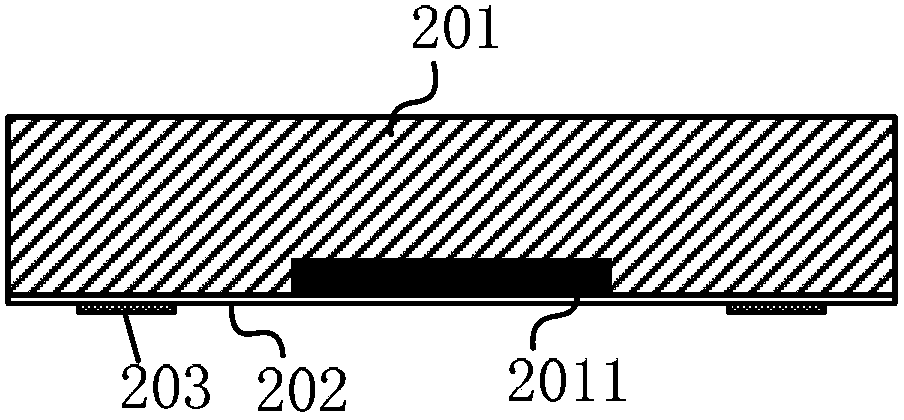

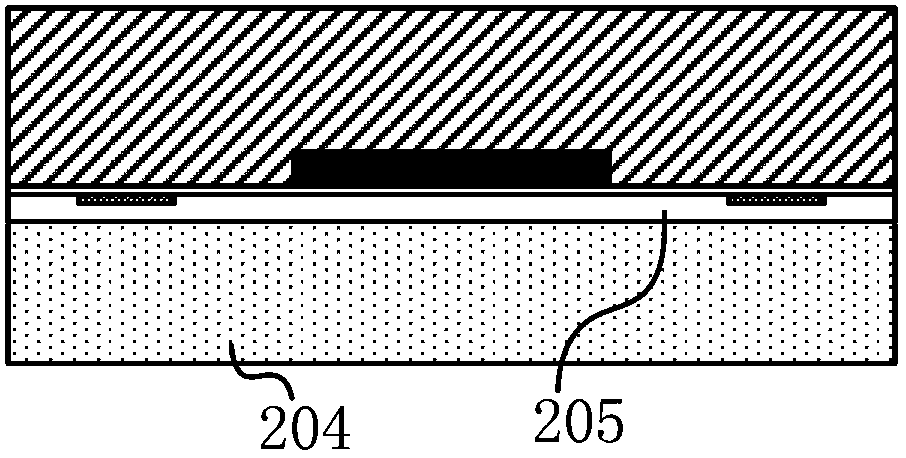

[0068] This embodiment provides a wafer-level packaging method for an image sensor, such as Figure 2a to Figure 2k As shown, the flow of this method is:

[0069] A) Fabricate a sensing wafer 201, and form a first passivation layer 202 on the active surface of the sensing wafer 201; wherein, the preset manufacturing process of the sensing wafer 201 includes: setting a Wafer; image sensing unit 2011 is formed on the front side of each chip; so far, the wafer constitutes a sensing wafer.

[0070] Specifically, the wavelength band used by the image sensing unit is in the visible light range, the standard thickness of the sensing wafer is preferably 350um, and the material of the sensing wafer is preferably gallium arsenide GaAs.

[0071] B) Depositing at least one metal fanning electrode 203 on the first passivation layer 202 ; the metal fanning electrode 203 is distributed around the image sensing unit 2011 .

[0072] Specifically, the metal fanning electrodes 203 are distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com