Copper alloy wire used for semiconductor devices

A copper alloy and semiconductor technology, applied in the field of copper alloy wires with manganese and/or zinc elements, can solve the problems of material cost reduction, achieve improved physical and chemical properties, high heat softening degree, improved oxidation resistance and corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be practiced.

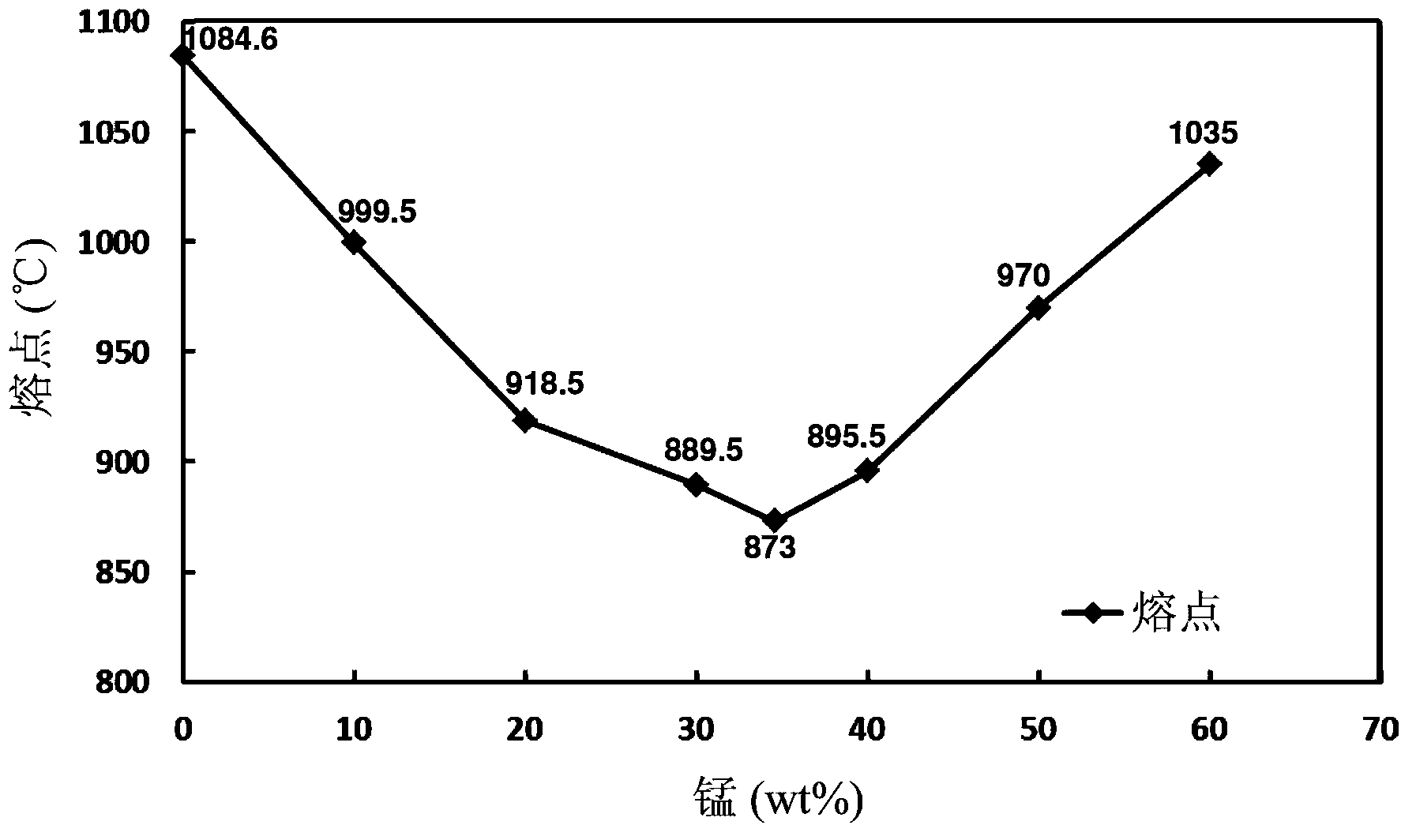

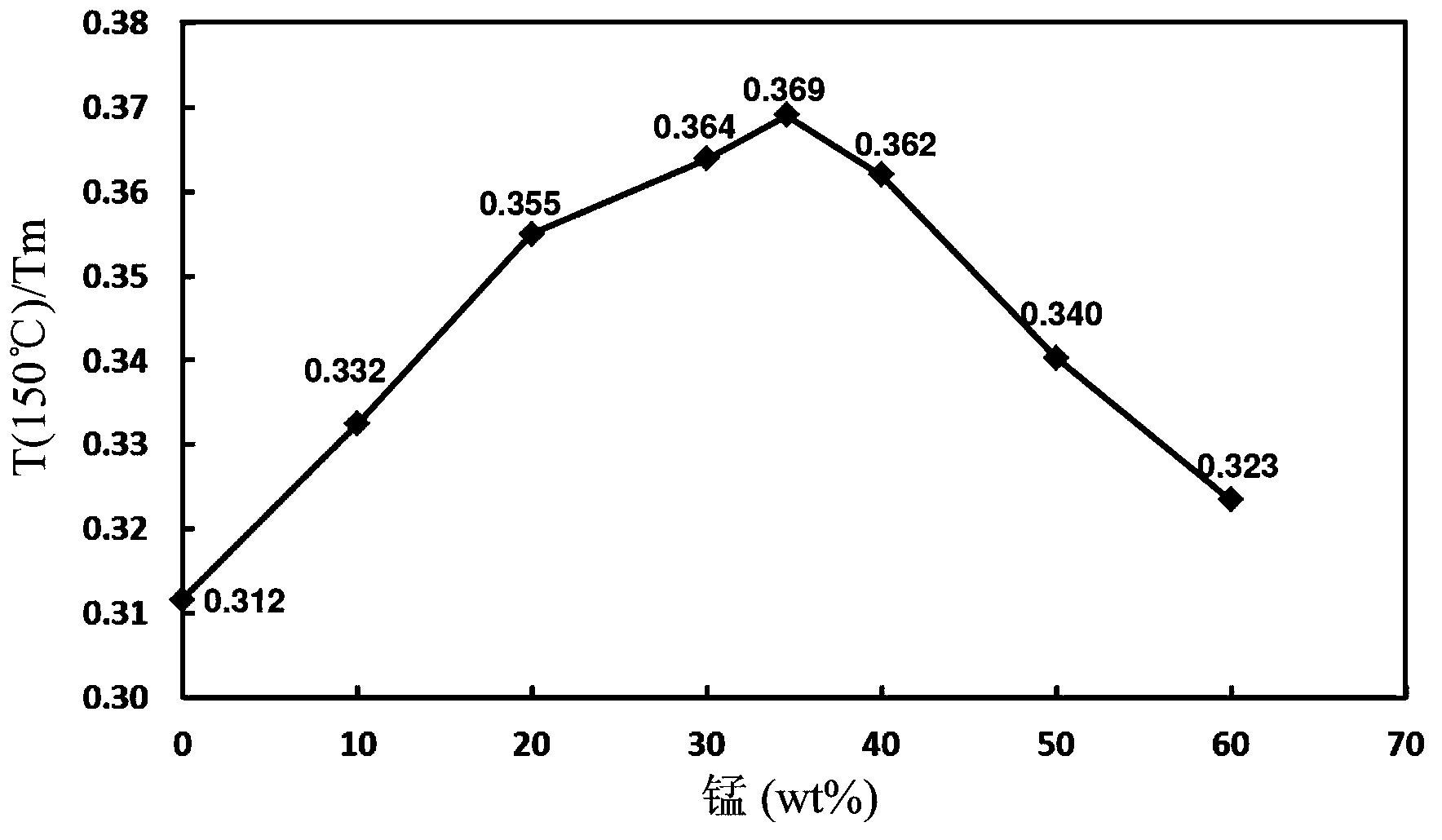

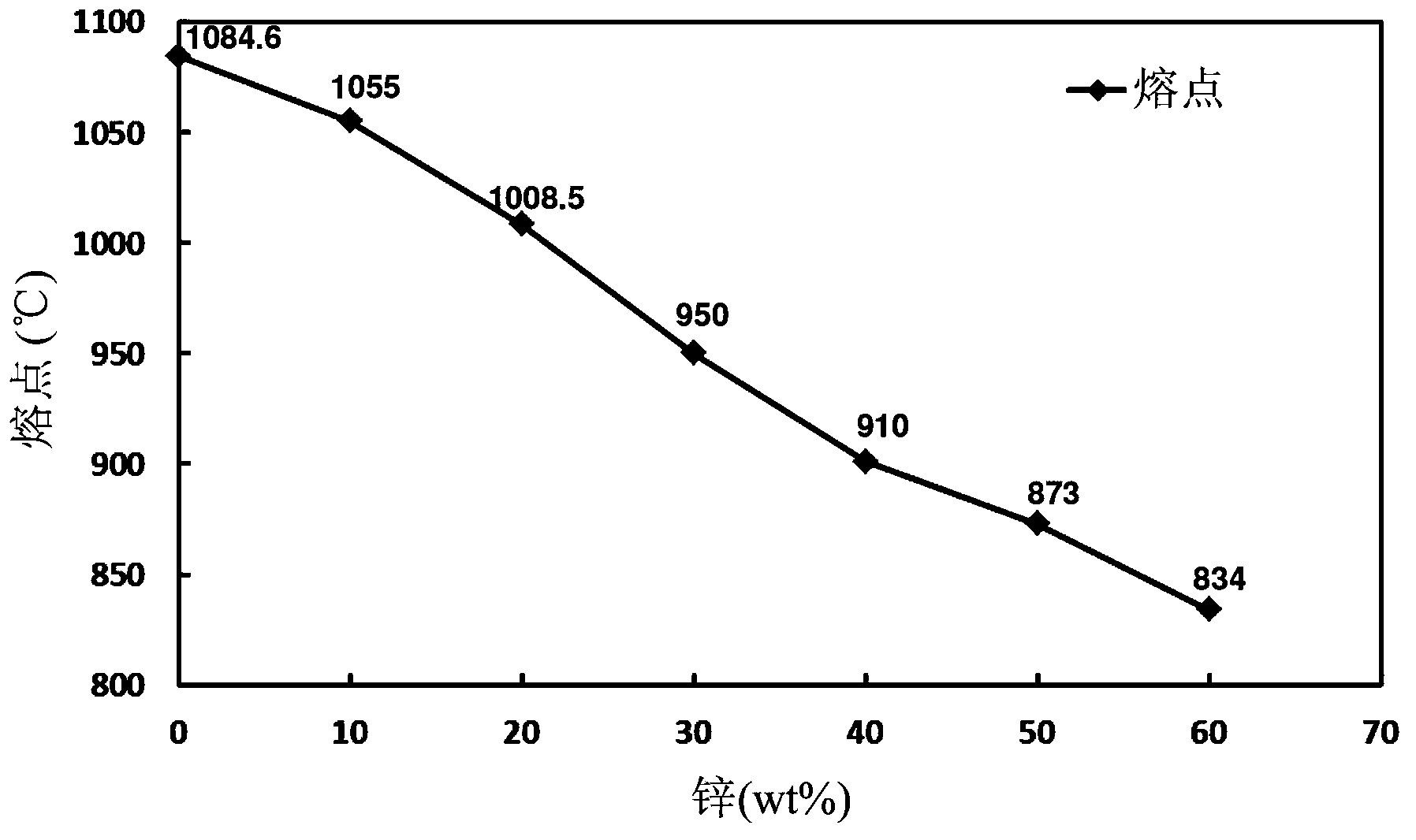

[0021] First, in an embodiment of the present invention, the present invention can provide a copper / manganese alloy wire, which is mainly used in the packaging and bonding process of semiconductor chips, to be electrically connected to an aluminum pad and a carrier of a semiconductor chip. Between the welding pads of the board, wherein the copper / manganese alloy wire of the present embodiment mainly comprises copper (Cu) base material, and the manganese (Mn) element of a specific weight ratio (wt%) is mixed, and above-mentioned specific weight ratio can be 20wt% to 40wt% manganese, with the balance being copper, for example comprising 22wt% to 38wt% manganese, 34wt% to 35wt% manganese, or 34.6wt% manganese. In the copper alloy wire of this embodiment, the manganese element is completely dissolved i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com