Preparation method of high-viscosity and high-elasticity asphalt and high-viscosity and high-elasticity asphalt

A highly elastic, asphalt technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

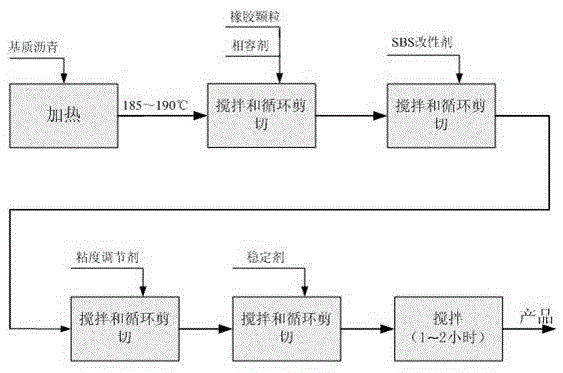

[0032] as per figure 1 The technological process for preparing high-viscosity and high-elasticity asphalt:

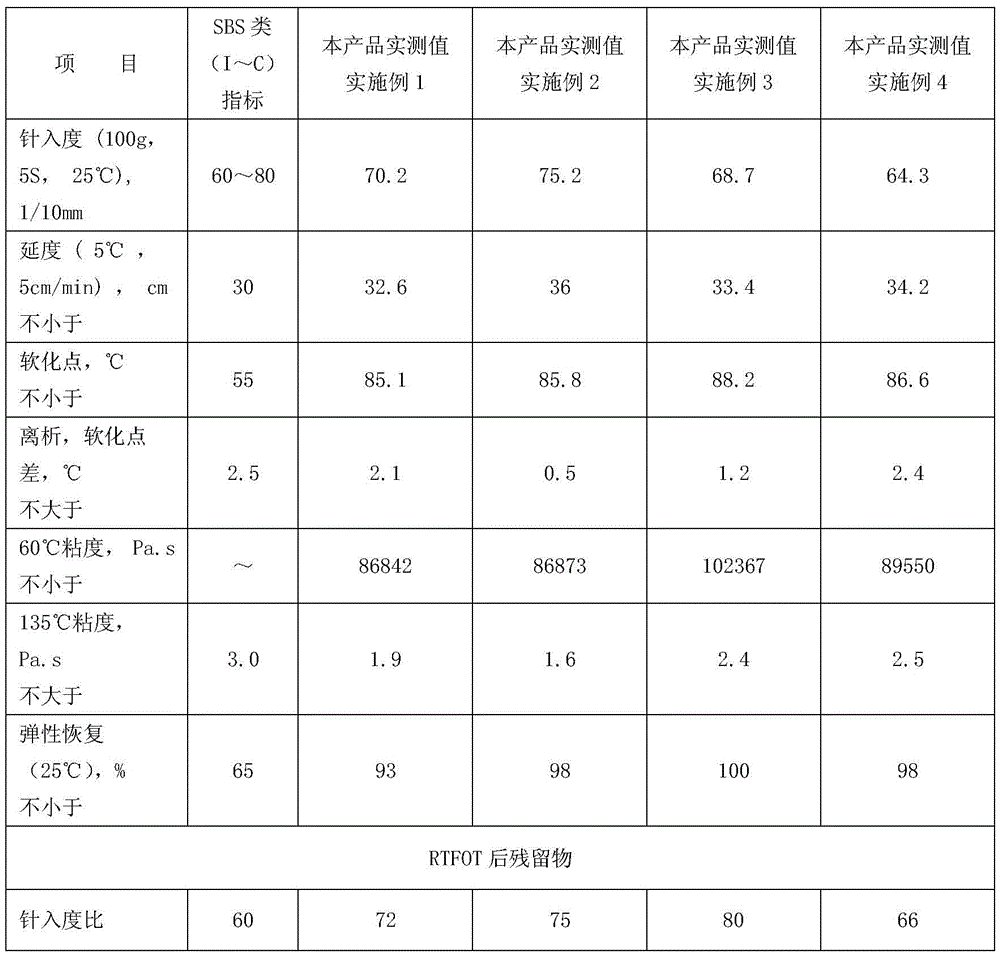

[0033] 1) select raw materials: select each raw material and its percentage by weight are: 6% compatibilizer, 4% rubber granules, 5% SBS, 2% viscosity regulator, 0.4% stabilizer, and others are matrix asphalt;

[0034] 2) Heat the base asphalt measured in proportion to 185-190°C;

[0035] 3) Add compatibilizer and rubber particles into the above base asphalt in proportion, control the temperature at 185-190°C, stir and circularly shear the above mixture until the rubber particles are fine and uniform;

[0036] 4) Add the SBS modifier to the above mixture in proportion, control the temperature at 185-190°C, stir and shear until there are no obvious particles;

[0037] 5) Add the viscosity modifier to the above mixture in proportion, control the temperature at 185-190°C, stir and shear until there are no obvious particles;

[0038] 6) Divide the appropriate proportion ...

Embodiment 2

[0040] Keep the preparation method of embodiment 1 unchanged, wherein choose the raw material of high-viscosity high-elasticity asphalt and its percentage by weight to be: 6% compatibilizer, 5% rubber particles, 7% SBS modifier, 3% viscosity Regulator, 0.3% stabilizer, the others are base asphalt.

Embodiment 3

[0042] Keep the preparation method of embodiment 1 unchanged, wherein choose the raw material of high-viscosity high-elasticity bitumen and its percentage by weight to be: 7% compatibilizer, 4% rubber particle, 6% SBS modifier, 3% viscosity Regulator, 0.3% stabilizer, the others are base asphalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com