Preparation method of nanometer microporous thermal insulation material

A technology for thermal insulation materials and manufacturing methods, which is applied in the field of manufacturing nano-microporous thermal insulation materials, and can solve problems such as damaging the high-temperature performance of thermal insulation materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The design specifications of the nano-microporous insulation material products are 300mm (length) × 300mm (width) × 30mm (height). It is composed of nano-silica, infrared shading agent, refractory and ceramic fiber. Accurately weigh the above raw materials, first disperse the ceramic fibers with a high-speed mixer, then add other raw materials and the dispersed ceramic fibers in turn into the mixer, and continue stirring until the mixture is uniform. Composition bulk density 40Kg / m 3 , The average particle size of the powder is 30-50 nanometers, the diameter of the ceramic fiber is 6 microns, and the length is 5mm.

[0027] The cavity size is 309mm (length) × 309mm (width) × 186mm (height). The diameter of the small holes through the die bottom plate and the punch plate is 1mm, and they are distributed equidistantly in a 10mm square. Lay a 320-mesh screen on the bottom of the mold, load the material, and then cover the surface of the powder with a 320-mesh screen. S...

Embodiment 2

[0030] The design specifications of the nano-microporous insulation material products are 300mm (length) × 300mm (width) × 20mm (height). Its composition and raw material processing method are with embodiment 1.

[0031] The cavity size is 309mm (length) × 309mm (width) × 124mm (height). The diameter of the small holes through the die bottom plate and the punch plate is 1mm, and they are distributed equidistantly in a 12mm square. Lay a mesh of less than 320 mesh on the bottom of the mold, load the material, and then cover the surface of the powder with a mesh of 320 mesh. Start the press, the pressure is 2MPa. When it is compressed to a cavity height of 24mm, stop the punch from descending, keep the pressure for 1 minute, and then unload. Stay for a while, waiting for the green body to rebound. Then press again to the cavity height of 20mm (overpressure 3%), keep the pressure for 1 minute again, demould, the green body rebounds to a height of 20.6mm, that is, the size of ...

Embodiment 3

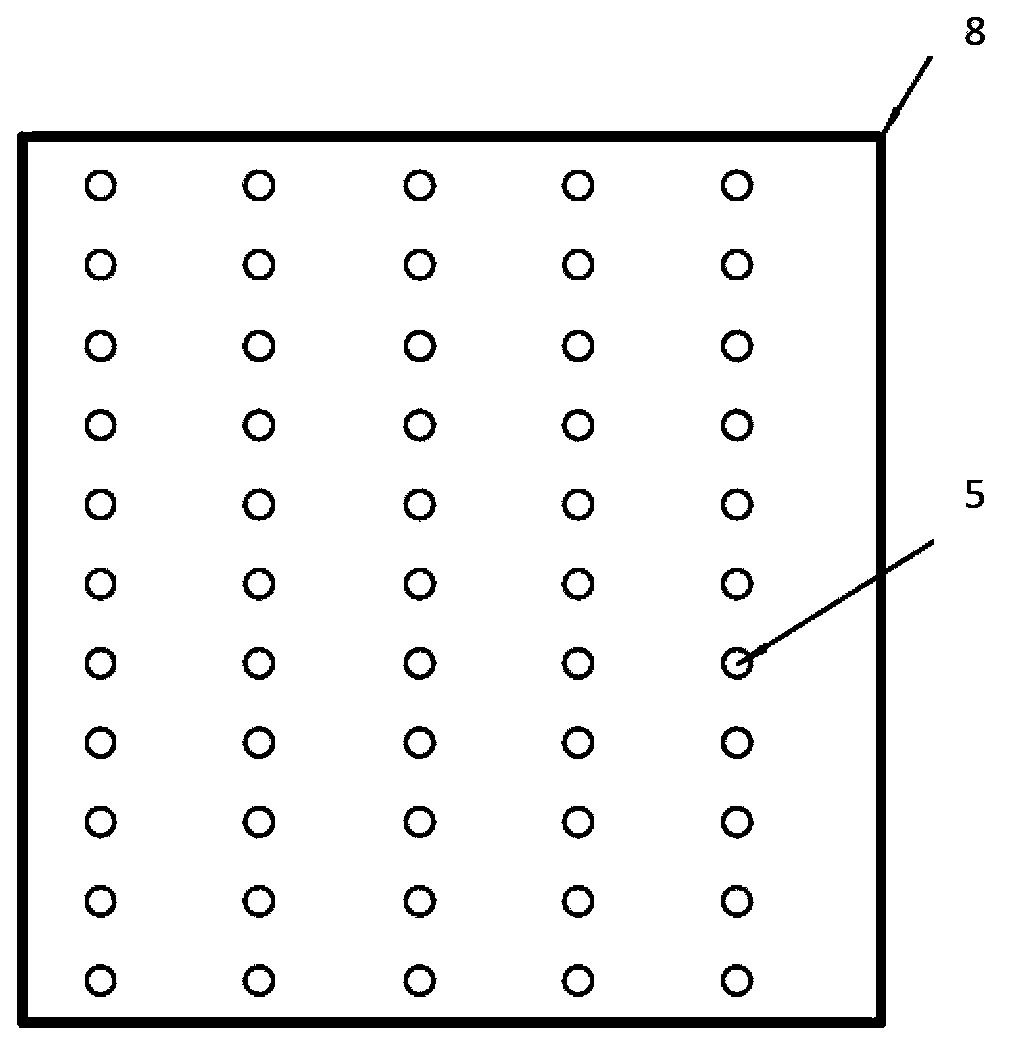

[0034] figure 1 It is a schematic diagram of the distribution of the exhaust holes on the bottom plate of the mold and the upper punch panel. The diameter of the exhaust holes is 0.5-1mm, and they are distributed equidistantly in a square of 8-12mm. The size and spacing of the holes can be adjusted according to the exhaust requirements. For compression For ceramic materials with a ratio of 500-800%, the above vent holes are suitable.

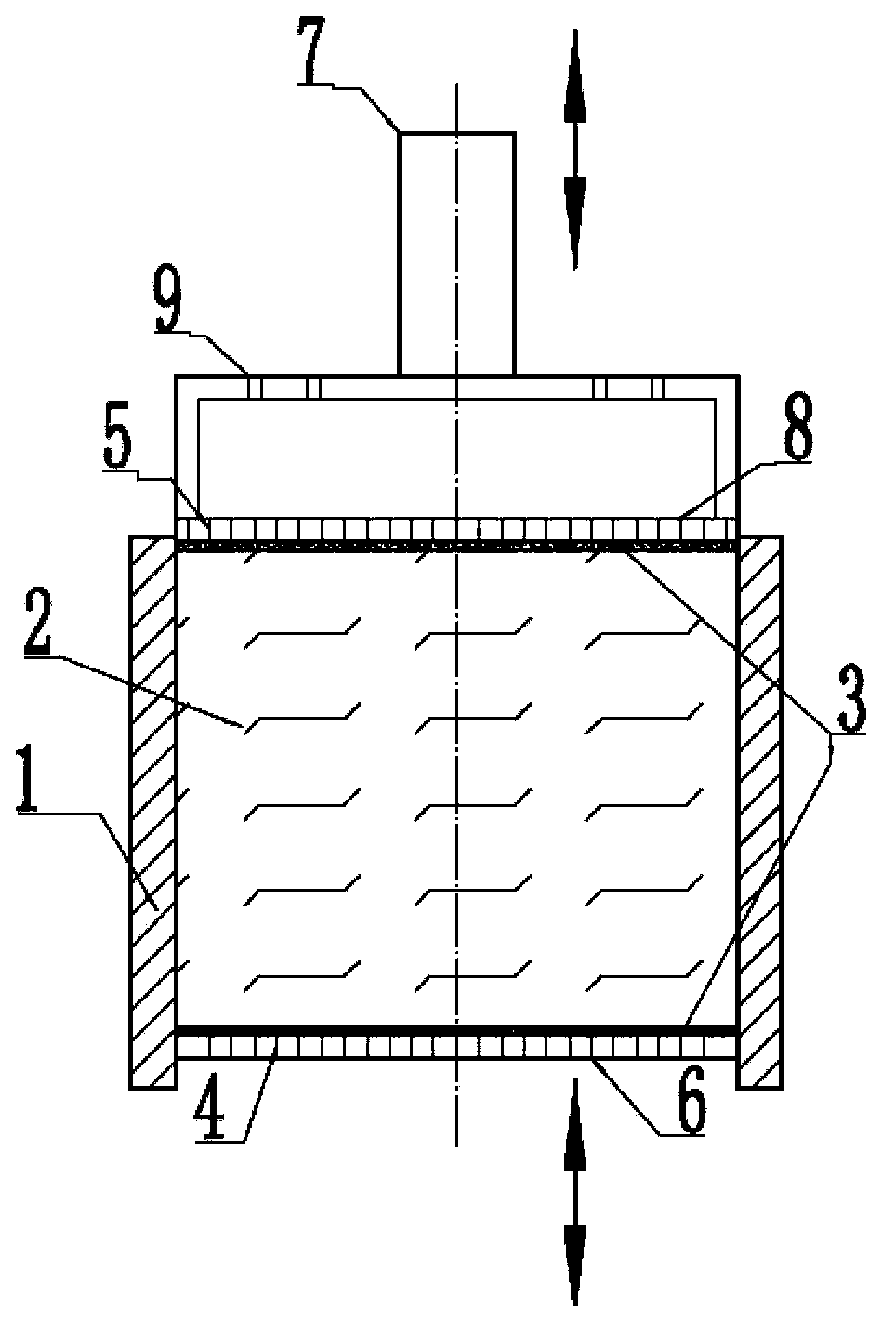

[0035] figure 2It is a schematic diagram of double-sided press molding. In the figure, 1. Die wall, 2. Composition powder, 3. Sand net, 4. Lower vent hole, 5. Upper vent hole, 6. Movable mold bottom plate, 7. Punch Head, 8. Punch panel, 9. Punch vent.

[0036] Using double-sided pressure and opening through holes on the bottom plate of the mold and the upper punch panel ( figure 1 shown) is suitable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Average granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com