Secondary cooling method and secondary cooling device for continuous casting machine

A secondary cooling and casting machine technology, which is applied in the field of secondary cooling devices, can solve problems such as the decrease in the rigidity of the backing roll, the inability to fully support the slab, and the possibility of bulging, etc., to achieve the effect of improving cooling uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

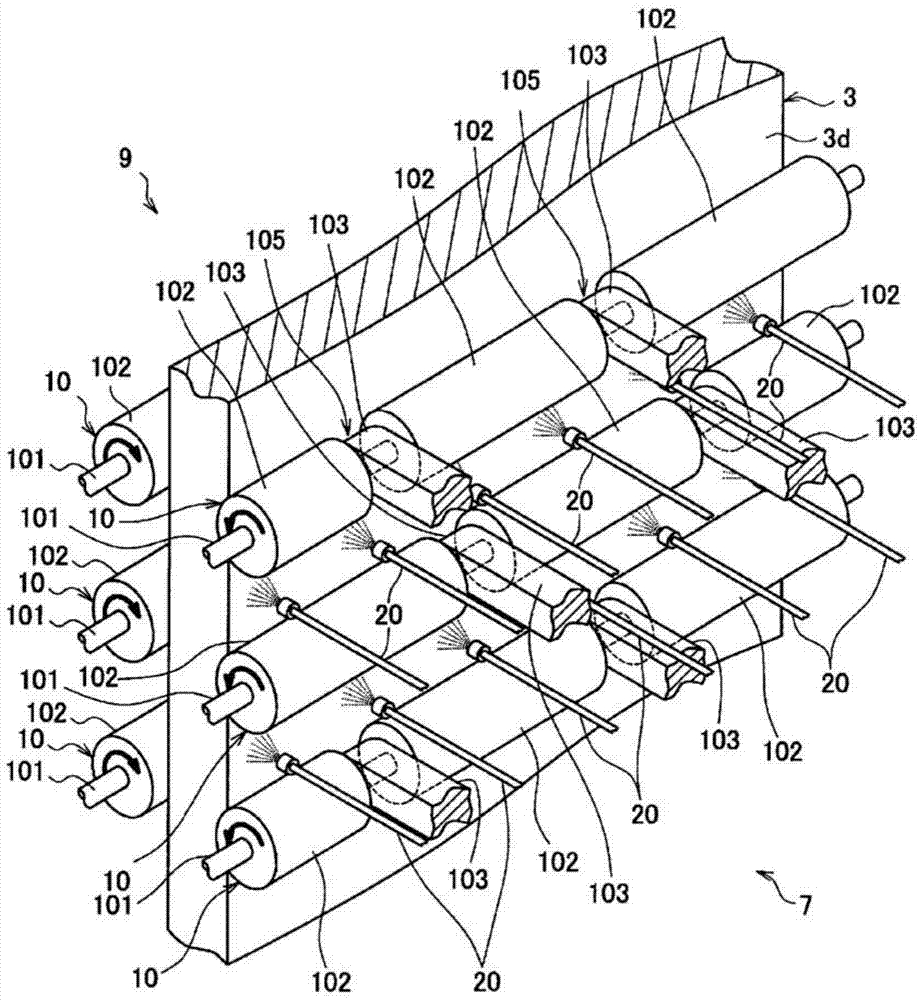

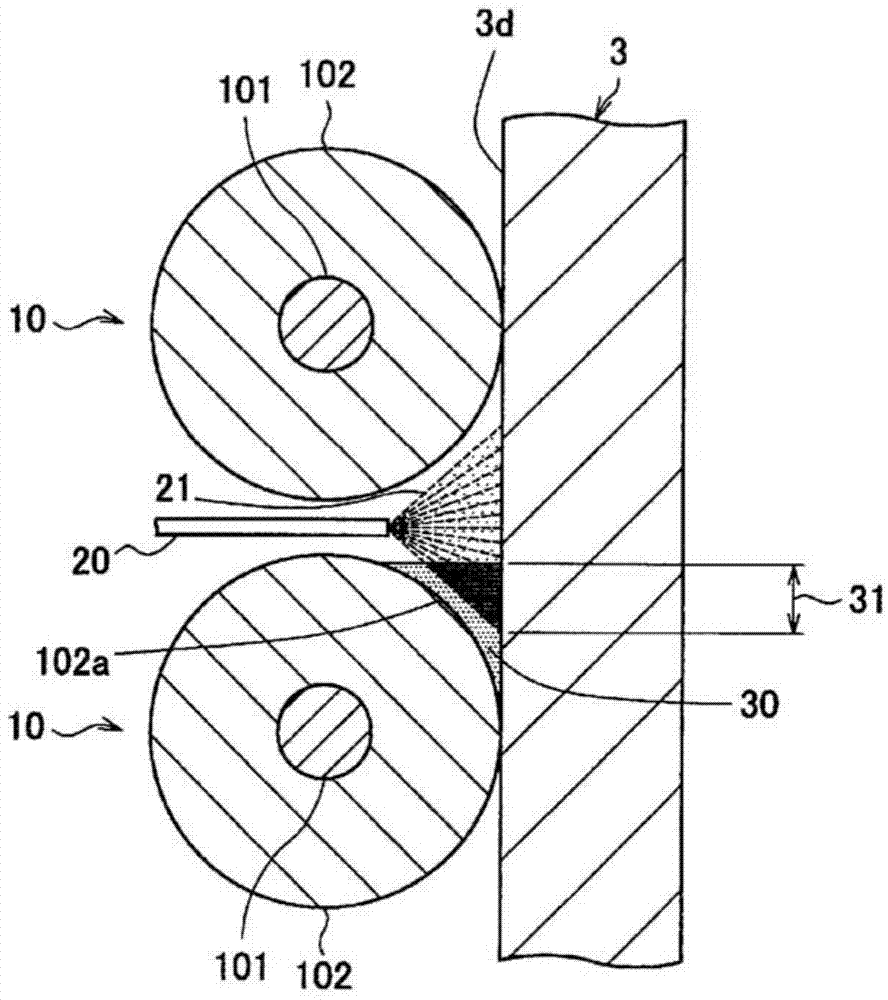

[0052] 1.1. Overall structure of continuous casting machine

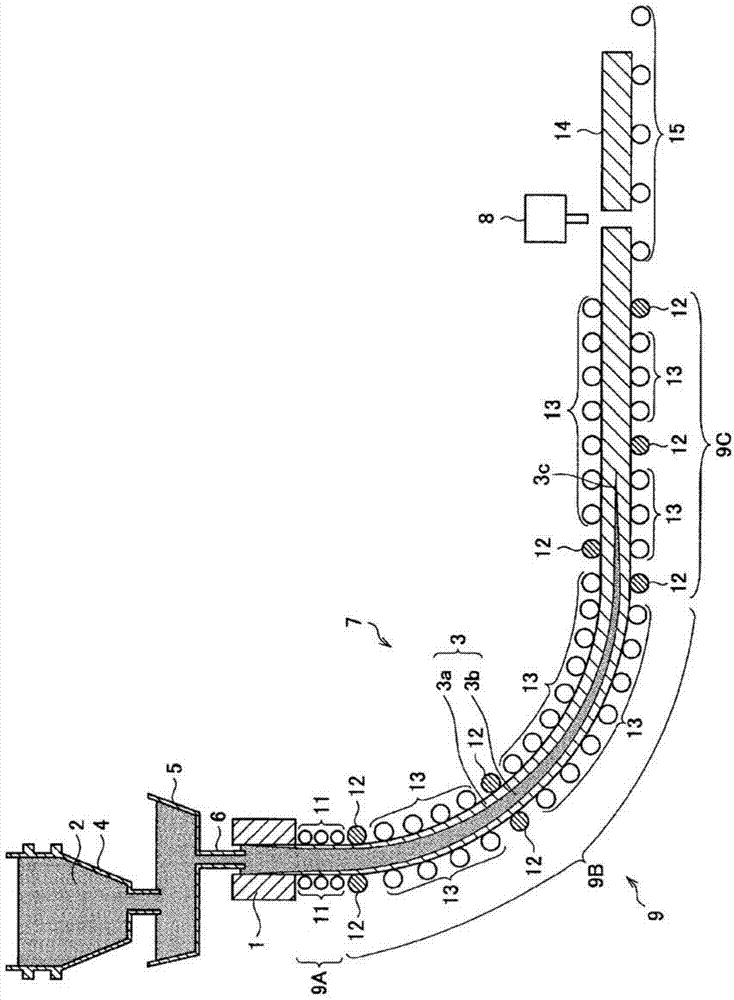

[0053] First, refer to figure 1 , the overall structure of the continuous casting machine according to the first embodiment of the present invention will be described. figure 1 It is a side sectional view showing the continuous casting machine of this embodiment.

[0054] Such as figure 1 As shown, the continuous casting machine is an apparatus for continuously casting a molten metal 2 (for example, molten steel) using a continuous casting mold 1 to manufacture a slab 3 such as a slab. The above-mentioned continuous casting machine has a casting mold 1 , a ladle 4 , a tundish 5 , a dipping nozzle 6 , a secondary cooling device 7 , and a billet cutter 8 .

[0055] The ladle 4 is a movable container for transferring the molten metal 2 to the tundish 5 from the outside. The ladle 4 is arranged above the tundish 5 , and the molten metal 2 inside the ladle 4 is supplied to the tundish 5 . The tundish 5 is disposed a...

no. 2 approach

[0136] Next, the roll shape and nozzle arrangement of the secondary cooling device 7A of the continuous casting machine according to the second embodiment of the present invention will be described. Compared with the first embodiment, the second embodiment is different in that two split rolls are used, and the grooves of the back-up roll 10 through which the cooling water can flow In addition to the bearing part 103 between them, there are slits for water passage formed on the peripheral surface of each divided roller part 102, and other functional structures are the same as those of the above-mentioned first embodiment.

[0137] Figure 11 It is a front view showing the arrangement of the backup roll 10 and the nozzle 20 of the secondary cooling device 7A of the second embodiment. Such as Figure 11 As shown, each backup roll 10 is composed of two divided rolls, and has two divided roll parts 102A, 102B and one bearing part 103 provided between the two divided roll parts 102A...

no. 3 approach

[0148] Next, the roll shape and nozzle arrangement of the secondary cooling device 7B of the continuous casting machine according to the third embodiment of the present invention will be described. Compared with the first embodiment, the third embodiment is different in that two split rolls are used, and a plurality of thin slits for water passage are formed on the peripheral surface of the split roll portion 102 of the backup roll 10, and other functional structures It is the same as the first embodiment described above.

[0149] Figure 12 It is a front view showing the arrangement of the backup roll 10 and the nozzle 20 of the secondary cooling device 7B of the third embodiment. Such as Figure 12 As shown, each backup roll 10 is composed of two divided rolls, and has two divided roll parts 102A, 102B and one bearing part 103 provided between these two divided roll parts 102A, 102B. The bearings 103 respectively provided on the upstream backup roll 10 (upper roll) and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com