Agave americana fiber-reinforced environment-friendly friction material and preparation method thereof

A technology of safflower fiber and friction material, applied in the field of safflower fiber reinforced environment-friendly friction material and its preparation, can solve problems such as reducing density and material friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

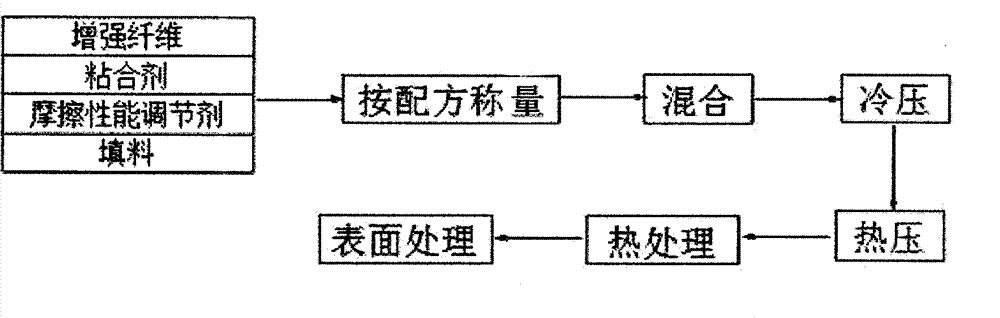

[0034] Safflower fiber reinforced environment-friendly friction material adopts high temperature resistant polyimide modified epoxy resin as binder, three kinds of fibers as hemp fiber, high-strength high-modulus polyethylene fiber and basalt fiber are used as hybrid reinforcement fibers, and corundum is added Friction-increasing materials, copper powder, and artificial graphite are used as friction performance regulators to improve and enhance the friction performance of friction materials. In order to improve the production efficiency and the qualification rate of friction materials, the friction materials were prepared by a process of 2-step heating, 3-time degassing, and temperature-controlled curing. The product has simple molding process, good physical and mechanical properties, small attenuation of friction coefficient with temperature rise, good comprehensive performance, safe and effective braking, comfortable and stable ride, and meets the humanized design requirement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com