Flame retardant acrylate adhesive

An acrylate and adhesive technology, applied in the direction of ester copolymer adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve problems such as hidden quality problems, adhesive layer burning, and debonding of load-bearing parts , to achieve the effect of increasing the flash point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Proportion Curing agent component Main agent component

[0022] Methyl Methacrylate 26%Wt 21%Wt

[0023] Hydroxyethyl Methacrylate 22%Wt 40%Wt

[0024] Methacrylic acid 14%Wt 6%Wt

[0025] 2-Hydroxyethyl methacrylate phosphate 5%Wt -

[0026] ABS 5.5%Wt 4.5%Wt

[0027] Nitrile Rubber 12%Wt 12%Wt

[0028] Substituted Thiourea 3%Wt -

[0029] Amines 2.5%Wt -

[0030] 1,4-Hydroquinone - 0.2% Wt

[0031] Flame Retardant 10%Wt 10%Wt

[0032] Cumene Hydroperoxide - 4.8%Wt

[0033] Benzoyl Peroxide - 1.5% Wt.

[0034] Preparation:

[0035] (1) Main agent: put monomethacrylate monomer and methacrylic acid into the reaction kettle, add elastomer, stir until the elastomer is completely dissolved, add epoxy resin, stabilizer, stir evenly, add cumene over Hydrogen peroxide, benzoyl peroxide, stir well.

[0036] (2) Curing agent components: Put monomethacrylate monomer and methacrylic acid into the reaction kettle, add elastomer, stir until the elastomer is complete...

Embodiment 2

[0043] Proportion Curing agent component Main agent component

[0044] Methyl Methacrylate 23%Wt 20%Wt

[0045] Hydroxyethyl Methacrylate 25%Wt 40%Wt

[0046] Methacrylic acid 11%Wt 5%Wt

[0047] 2-Hydroxyethyl methacrylate phosphate 5%Wt -

[0048] ABS 5.5%Wt 4.5%Wt

[0049] Nitrile Rubber 12%Wt 12%Wt

[0050] Substituted Thiourea 3%Wt -

[0051] Amines 2.5%Wt -

[0052] 1,4-Hydroquinone - 0.2% Wt

[0053]Flame Retardant 13%Wt 12%Wt

[0054] Cumene Hydroperoxide - 4.8%Wt

[0055] Benzoyl Peroxide - 1.5% Wt.

[0056] The preparation method is the same as in Example 1.

[0057] The performance test is the same as in Example 1.

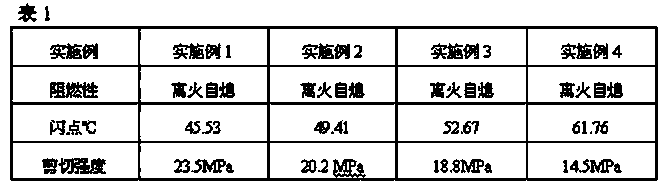

[0058] The test results are shown in Table 1.

Embodiment 3

[0060] Proportion Curing agent component Main agent component

[0061] Methyl Methacrylate 20%Wt 19%Wt

[0062] Hydroxyethyl Methacrylate 28%Wt 41%Wt

[0063] Methacrylic acid 8%Wt 5%Wt

[0064] 2-Hydroxyethyl methacrylate phosphate 5%Wt -

[0065] ABS 5.5%Wt 4.5%Wt

[0066] Nitrile Rubber 12%Wt 12%Wt

[0067] Substituted Thiourea 3.5%Wt -

[0068] Amines 3%Wt -

[0069] 1,4-Hydroquinone - 0.2% Wt

[0070] Flame Retardant 15%Wt 12%Wt

[0071] Cumene Hydroperoxide - 4.8%Wt

[0072] Benzoyl Peroxide - 1.5% Wt.

[0073] The preparation method is the same as in Example 1.

[0074] The performance test is the same as in Example 1.

[0075] The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com