Polyurea wear-resistant coating material with anti-static function and preparation method thereof

A wear-resistant coating and anti-static technology, applied in the direction of conductive coatings, can solve the problems of sensitive equipment damage, no consideration, etc., and achieve the effects of excellent electrical conductivity, good construction, good surface effect and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

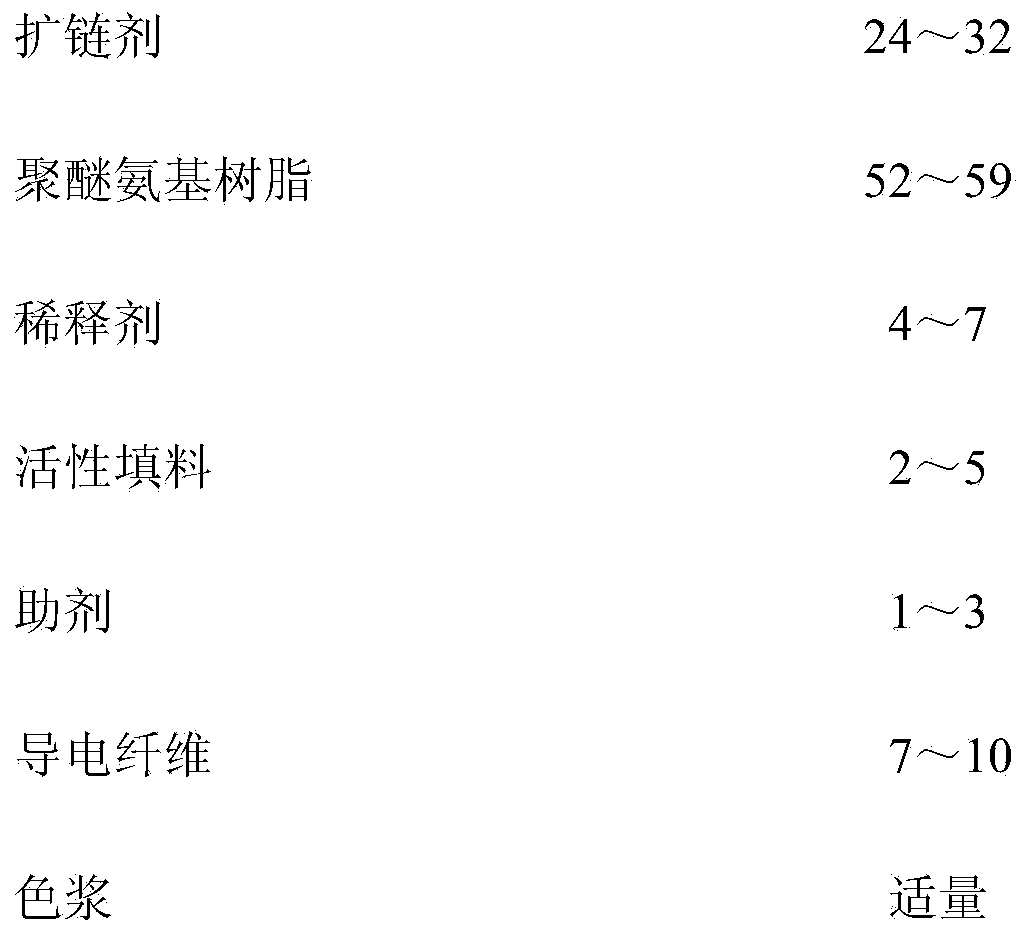

Method used

Image

Examples

Embodiment 1

[0046] Preparation of component A of polyurea wear-resistant coating material with antistatic function:

[0047] Pump 41 parts of polyether diol into the reaction kettle, heat up to about 90°C (85°C-95°C) for dehydration for 1-2 hours, stop dehydration when the moisture content reaches below 0.08%; cool to about 80°C to react Add 55 parts of diphenylmethane diisocyanate to the kettle while stirring to react, the reaction temperature is controlled at 80±5°C, and keep warm for 3 hours; then cool down to 60°C and add 4 parts of phthalic acid diisocyanate to the above reaction kettle while stirring Isononyl ester, measure the NCO content after 15 minutes, and thus prepare the A component.

[0048] Preparation process of component B of polyurea wear-resistant coating material with antistatic function:

[0049] 17 parts of 3,5-diethyltoluenediamine, 8 parts of 4,4'-bis-sec-butylaminodiphenylmethane, 53 parts of Huntsman's D2000, 4 parts of Huntsman's T5000, 5 parts of o-benzene Ad...

Embodiment 2

[0052] Preparation of component A of polyurea wear-resistant coating material with antistatic function:

[0053] Pump 42 parts of polyether diol into the reaction kettle, heat up to about 90°C (85°C-95°C) for dehydration for 1-2 hours, stop dehydration when the moisture content reaches below 0.08%; cool to about 80°C to react Add 54 parts of diphenylmethane diisocyanate to the kettle for reaction while stirring. The reaction temperature is controlled at 80±5°C and kept for 3 hours; then the temperature is lowered to 60°C and 4 parts of phthalic acid di Isononyl ester, measure the NCO content after 15 minutes, and thus prepare the A component.

[0054] Preparation process of component B of polyurea wear-resistant coating material with antistatic function:

[0055]15 parts of 3,5-diethyltoluenediamine, 10 parts of 4,4'-bis-sec-butylaminodiphenylmethane, 51 parts of Huntsman's D2000, 5 parts of Huntsman's T5000, 5 parts of o-benzene Add dimethyl diisononyl ester and 3 parts of ...

Embodiment 3

[0058] Preparation of component A of polyurea wear-resistant coating material with antistatic function:

[0059] Pump 41 parts of polyether diol into the reaction kettle, heat up to about 90°C (85°C-95°C) for dehydration for 1-2 hours, stop dehydration when the moisture content reaches below 0.08%; cool to about 80°C to react Add 55 parts of diphenylmethane diisocyanate to the kettle while stirring to react, the reaction temperature is controlled at 80±5°C, and keep warm for 3 hours; then cool down to 60°C and add 4 parts of phthalic acid diisocyanate to the above reaction kettle while stirring Isononyl ester, measure the NCO content after 15 minutes, and thus prepare the A component.

[0060] Preparation process of component B of polyurea wear-resistant coating material with antistatic function:

[0061] 20 parts of 3,5-diethyltoluenediamine, 7 parts of 4,4'-bis-sec-butylaminodiphenylmethane, 52 parts of Huntsman's D2000, 3 parts of Huntsman's T5000, 5 parts of o-benzene Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com