Anti-static reflective coating

A reflective coating and anti-static technology, applied in reflective/signal coatings, conductive coatings, polyurea/polyurethane coatings, etc., can solve problems such as protection and energy saving, unsatisfactory anti-static effect, and unstable coating performance. , to achieve good light reflection performance, excellent anti-static effect, and stable coating performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

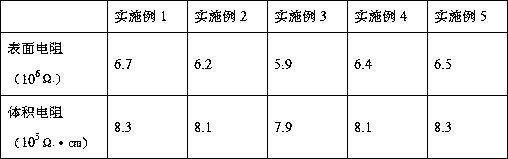

Embodiment 1

[0014] An antistatic reflective coating, which consists of the following components in parts by weight: 25 parts of water-based acrylic emulsion, 12 parts of barium sulfate, 4 parts of superfine aluminum silicate, 10 parts of tin oxide, 5 parts of sunfast yellow, and 5 parts of titanium dioxide , 0.5 parts of propylene glycol methyl ether, 0.5 parts of coupling agent, and 12 parts of water. The color of the finished coating is yellow.

Embodiment 2

[0016] An antistatic reflective coating, which is composed of the following components by weight: 40 parts of water-based acrylic emulsion, 18 parts of barium sulfate, 7 parts of ultrafine aluminum silicate, 15 parts of tin oxide, 8 parts of fast yellow, and 10 parts of titanium dioxide , 1.5 parts of propylene glycol methyl ether, 2 parts of coupling agent, and 22 parts of water. The color of the finished coating is yellow.

Embodiment 3

[0018] An antistatic reflective coating, which is composed of the following components by weight: 32 parts of water-based acrylic emulsion, 15 parts of barium sulfate, 5 parts of superfine aluminum silicate, 12 parts of tin oxide, 6 parts of fast yellow, and 8 parts of titanium dioxide , 1 part of propylene glycol methyl ether, 1 part of coupling agent, and 18 parts of water. The color of the finished coating is yellow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com